- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China thin wafer handling Manufacturers, Suppliers, Factory

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for thin wafer handling,Porous Ceramic,vacuum chuck,black alumina,wafer transportation, Our business has already setup a professional, creative and responsible workforce to develop purchasers together with the multi-win principle.

thin wafer handling, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to offer our clients sincerely with qualified solutions, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Hot Products

Silicon Epitaxial Deposition In Barrel Reactor

If you need a high-performance graphite susceptor for use in semiconductor manufacturing applications, the Semicorex Silicon Epitaxial Deposition In Barrel Reactor is the ideal choice. Its high-purity SiC coating and exceptional thermal conductivity provide superior protection and heat distribution properties, making it the go-to choice for reliable and consistent performance in even the most challenging environments.PSS Etching Carrier Plate for Semiconductor

Semicorex PSS Etching Carrier Plate for Semiconductor is specially engineered for high-temperature and harsh chemical cleaning environments required for epitaxial growth and wafer handling processes. Our ultra-pure PSS Etching Carrier Plate for Semiconductor is designed to support wafers during thin-film deposition phases like MOCVD and epitaxy susceptors, pancake or satellite platforms. Our SiC coated carrier has high heat and corrosion resistance, excellent heat distribution properties, and a high thermal conductivity. We provide cost-effective solutions to our customers, and our products cover many European and American markets. Semicorex looks forward to being your long-term partner in China.TaC Coating Jig

Semicorex TaC Coating Jig stands as a pivotal component within the semiconductor manufacturing process, crafted meticulously from graphite and fortified with a resilient layer of tantalum carbide coating. This crucial equipment element embodies a fusion of cutting-edge materials science and precision engineering, designed to uphold stringent operational demands and exacting standards prevalent in semiconductor fabrication. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Coated Support Ring

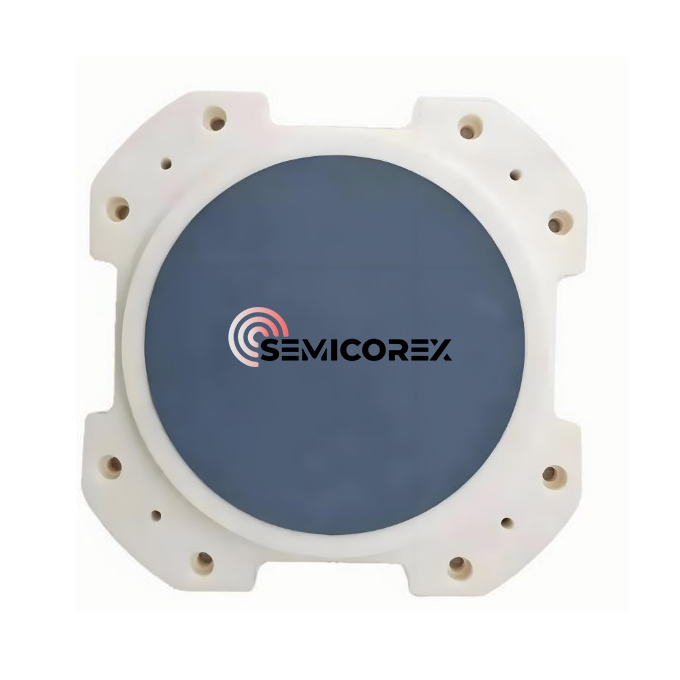

Semicorex SiC Coated Support Ring is an essential component used in the semiconductor epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC ICP Etching Disk

Semicorex SiC ICP Etching Disk is not merely components; it's essential enabler of cutting-edge semiconductor manufacturing as the semiconductor industry continues its relentless pursuit of miniaturization and performance, the demand for advanced materials like SiC will only intensify. It ensures the precision, reliability, and performance required to power our technology-driven world.We at Semicorex are dedicated to manufacturing and supplying high-performance SiC ICP Etching Disk that fuses quality with cost-efficiency.**SiC Multi Pocket Susceptor

Semicorex SiC Multi Pocket Susceptor represents a critical enabling technology in the epitaxial growth of high-quality semiconductor wafers. Fabricated through a sophisticated Chemical Vapor Deposition (CVD) process, these susceptors provide a robust and high-performance platform for achieving exceptional epitaxial layer uniformity and process efficiency.**