- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

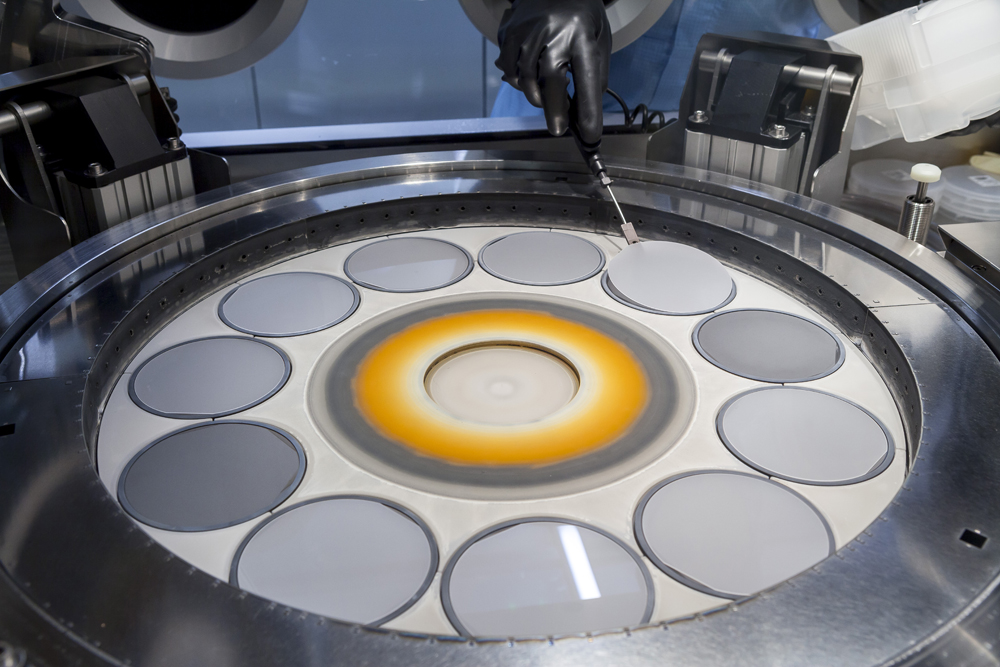

CVD TaC Coated Susceptor

Semicorex CVD TaC Coated Susceptor is a premium solution designed for MOCVD epitaxial processes, providing outstanding thermal stability, purity, and corrosion resistance under extreme process conditions. Semicorex focuses in precision-engineered coating technology that ensures consistent wafer quality, extended component lifetime, and reliable performance in every production cycle.*

Send Inquiry

In an MOCVD system, the susceptor is the core platform upon which the wafers are placed during epitaxial growth. It is critical that accurate temperature control, chemical stability, and mechanical stability in reactive gases are maintained at temperatures above 1200 °C. The Semicorex CVD TaC coated susceptor is capable of accomplishing that by combining an engineered graphite substrate with a dense, uniform coating of tantalum carbide (TaC) made via chemical vapor deposition (CVD).

The quality of TaC includes its exceptional hardness, corrosion resistance, and thermal stability. TaC has a melting point of greater than 3800 °C, and as such is one of the most temperature-resistant materials today, making it suitable for use in MOCVD reactors, w

ith precursors that may be much hotter and highly corrosive. The CVD TaC coating provides a protective barrier between the graphite susceptor and reactive gases, for example, ammonia (NH₃), and highly reactive, metal-organic precursors. The coating prevents the chemical degradation of the graphite substrate, the formation of particulates in the deposition environment, and diffusion of impurities into the deposited films. These actions are critical for high quality, epitaxial films, since they may impact film quality.

Wafer susceptors are critical components for wafer preparation and epitaxial growth of Class III semiconductors, such as SiC, AlN, and GaN. Most wafer carriers are made of graphite and coated with SiC to protect against corrosion from process gases. Epitaxial growth temperatures range from 1100 to 1600°C, and the corrosion resistance of the protective coating is crucial to the wafer carrier's longevity. Research has shown that TaC corrodes six times slower than SiC in high-temperature ammonia and over ten times slower in high-temperature hydrogen.

Experiments have demonstrated that TaC-coated carriers exhibit excellent compatibility in the blue GaN MOCVD process without introducing impurities. With limited process adjustments, LEDs grown using TaC carriers exhibit performance and uniformity comparable to those grown using conventional SiC carriers. Therefore, TaC-coated carriers have a longer lifespan than both bare graphite and SiC-coated graphite carriers.

Using tantalum carbide (TaC) coatings can address crystal edge defects and improve crystal growth quality, making it a core technology for achieving "faster, thicker, and longer growth." Industry research has also shown that tantalum carbide-coated graphite crucibles can achieve more uniform heating, thereby providing excellent process control for SiC single crystal growth, thereby significantly reducing the probability of polycrystalline formation at the edge of the SiC crystal.

The CVD layer deposition method of TaC results in an extremely dense and adherent coating. CVD TaC is molecularly bonded to the substrate, in contrast to sprayed or sintered coatings, from which the coating would be subject to delamination. This translates into better adhesion, a smooth surface finish, and high integrity. The coating will withstand erosion, cracking, and peeling even while repeatedly thermally cycled in an aggressive process environment. This facilitates a longer service life of the susceptor and reduced maintenance and replacement costs.

The CVD TaC Coated Susceptor can be customized to suit a range of MOCVD reactor configurations, which include horizontal, vertical, and planetary systems. Customization includes coating thickness, substrate material, and geometry, allowing for optimization depending on the process conditions. Whether for GaN, AlGaN, InGaN or for other compound semiconductor materials, the susceptor provides stable and repeatable performance, both of which are essential to high-performance device processing.

The TaC coating offers greater durability and purity, but it also strengthens the mechanical properties of the susceptor with resistance to thermal deformation from repeated thermal stress. The mechanical properties ensure sustained wafer support and rotating balance during long deposition runs. Furthermore, the enhancement facilitates consistent reproducibility and equipment uptime.