- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

SiC Coating Flat Susceptor

Semicorex SiC Coating Flat Susceptor is a high-performance substrate holder designed for precise epitaxial growth in semiconductor manufacturing. Choose Semicorex for reliable, durable, and high-quality susceptors that enhance the efficiency and precision of your CVD processes.*

Send Inquiry

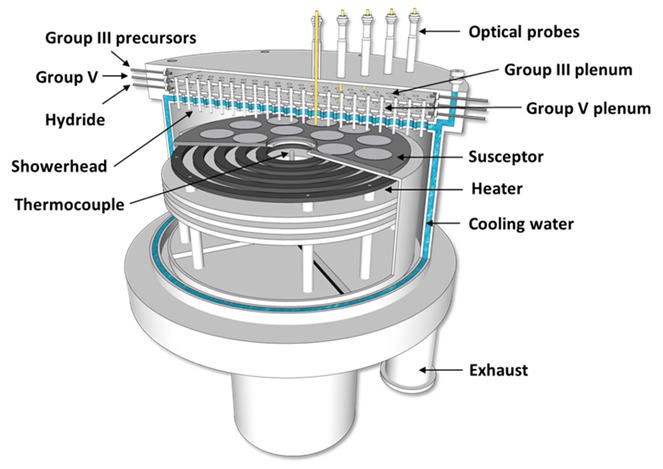

Semicorex SiC Coating Flat Susceptor is an essential waferholder designed for epitaxial growth processes in semiconductor manufacturing. Specifically engineered to support the deposition of epitaxial layers on substrates, this susceptor is ideal for high-performance applications such as LED devices, high-power devices, and RF communications technologies. By utilizing the CVD (Chemical Vapor Deposition) technique, it enables the precise growth of critical layers, such as GaAs on silicon substrates, SiC on conductive SiC substrates, and GaN on semi-insulating SiC substrates.

During the wafer manufacturing process, some wafer substrates need to further construct epitaxial layers to facilitate the manufacture of devices. Typical examples include LED light-emitting devices, which require the preparation of GaAs epitaxial layers on silicon substrates; SiC epitaxial layers are grown on conductive SiC substrates to construct devices such as SBDs and MOSFETs for high voltage, high current and other power applications; GaN epitaxial layers are constructed on semi-insulating SiC substrates to further construct HEMT and other devices for communication and other radio frequency applications. This process is inseparable from CVD equipment.

In CVD equipment, the substrate cannot be placed directly on metal or simply on a base for epitaxial deposition, because it involves various factors such as gas flow direction (horizontal, vertical), temperature, pressure, fixation, and falling contaminants. Therefore, a base is needed, and then the substrate is placed on a tray, and then epitaxial deposition is performed on the substrate using CVD technology. This base is a SiC-coated graphite base (also called a tray).

Applications

The SiC Coating Flat Susceptor is employed in various industries for different applications:

LED Manufacturing: In the production of GaAs-based LEDs, the susceptor holds silicon substrates during the CVD process, ensuring that the GaAs epitaxial layer is accurately deposited.

High-Power Devices: For devices like SiC-based MOSFETs and Schottky Barrier Diodes (SBDs), the susceptor supports the epitaxial growth of SiC layers on conductive SiC substrates, essential for high-voltage and high-current applications.

RF Communication Devices: In the development of GaN HEMTs on semi-insulating SiC substrates, the susceptor provides the stability needed to grow precise layers that are critical for high-frequency and high-performance RF applications.

The versatility of the SiC Coating Flat Susceptor makes it a vital tool in the growth of epitaxial layers for these diverse applications.

As one of the core components of MOCVD equipment, the graphite susceptor is the carrier and heating element of the substrate, which directly determines the uniformity and purity of the thin film material. Therefore, its quality directly affects the preparation of epitaxial wafers. At the same time, it is very easy to be worn out with the increase of usage times and changes in working conditions, and is a consumable.

The SiC Coating Flat Susceptor is designed to meet the stringent demands of the CVD process:

- Optimized Gas Flow: The flat design of the susceptor helps maintain consistent gas flow around the substrate, which is critical for the uniform deposition of epitaxial layers.

- Temperature Control: With its high thermal conductivity, the SiC Coating Flat Susceptor allows for precise control of the temperature during the deposition process. This ensures that the substrate remains within the required temperature range, which is essential for achieving the desired material properties.

- Easy Handling: The flat, smooth surface of the susceptor makes it easy to handle and load/unload substrates without causing damage to the delicate wafer or introducing contaminants.

By providing a stable, clean, and thermally efficient platform for epitaxial growth, the SiC Coating Flat Susceptor significantly improves the overall performance and yield of the CVD process.

Semicorex SiC Coating Flat Susceptor is engineered to meet the highest standards of precision and quality, guaranteeing outstanding performance in critical semiconductor manufacturing processes. We prove to deliver consistent products, reliable results in CVD systems, empowering the production of superior semiconductor devices. With remarkable chemical resistance, exceptional thermal management, and unparalleled durability, Semicorex SiC Coating Flat Susceptor stands out as the definitive choice for manufacturers aiming to optimize the wafer epitaxy processes.

Semicorex SiC Coating Flat Susceptor is an indispensable component in the fabrication of semiconductor devices that require epitaxial growth. Its superior durability, resistance to thermal and chemical stresses, and ability to maintain precise conditions during the deposition process make it essential for modern CVD systems. With the Semicorex SiC Coating Flat Susceptor, manufacturers gain a robust solution for achieving the highest quality epitaxial layers, guaranteeing excellent performance across numerous semiconductor applications. Partner with Semicorex to elevate your production process with products meticulously designed for optimal efficiency and reliability.