- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

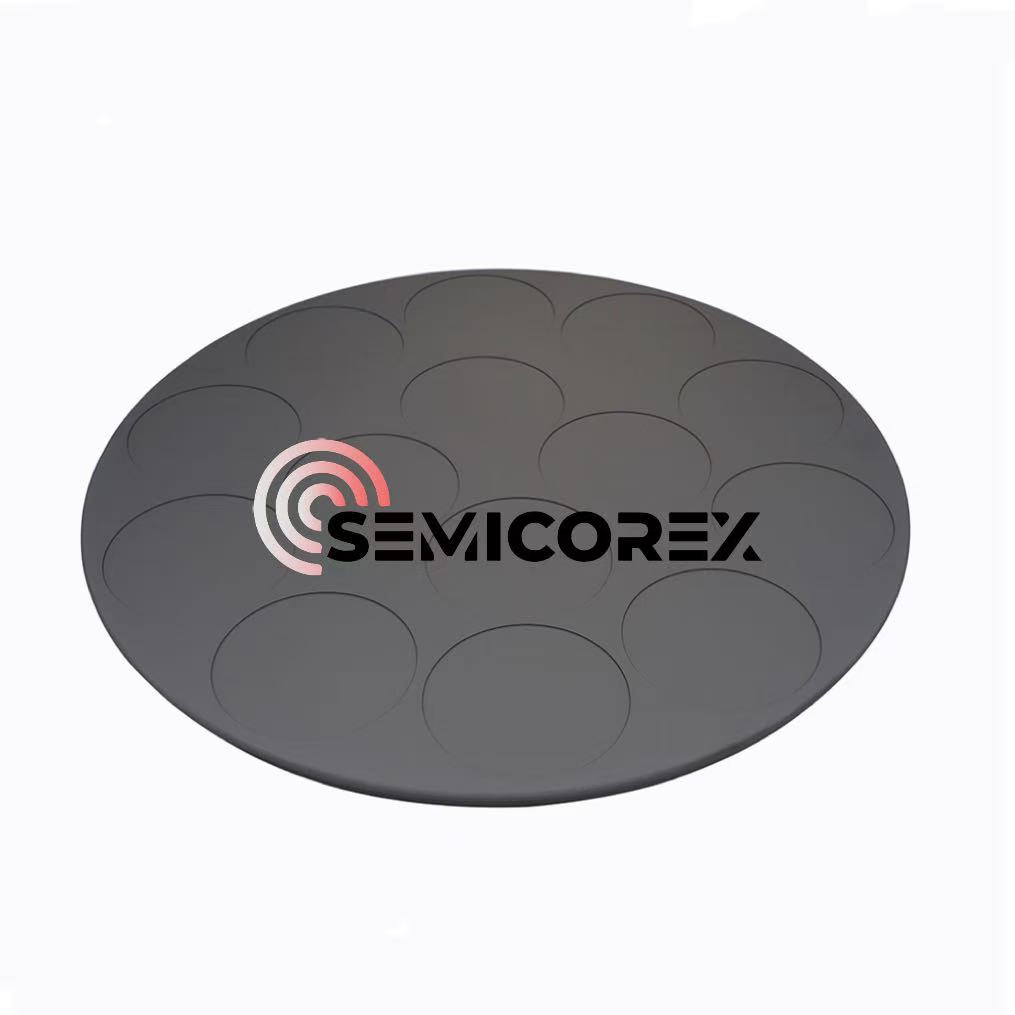

China Silicon Carbide Etching Fixture Plate Manufacturers, Suppliers, Factory

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Silicon Carbide Etching Fixture Plate,Etch Carrier(ICP/PSS),Silicon Carbide Etching Carrier,SiC processing Tray,Wafer Etching, We look forward to providing you with our goods while in the in close proximity to long term, and you will discover our quotation is extremely realistic as well as high-quality of our solutions is incredibly outstanding!

Silicon Carbide Etching Fixture Plate, We've got a good reputation for stable quality merchandise, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Hot Products

High-Temperature SiC-Coated Barrel Susceptor

When it comes to semiconductor manufacturing, the Semicorex High-Temperature SiC-Coated Barrel Susceptor is the top choice for superior performance and reliability. Its high-quality SiC coating and exceptional thermal conductivity make it ideal for use in even the most demanding high-temperature and corrosive environments.TaC Coated Plate

Semicorex TaC Coated Plate is a specialized disc designed for use in SiC epitaxial processes, crafted with precision from high-quality graphite material. Its surface is meticulously coated with tantalum carbide (TaC), a compound known for its exceptional purity and strength. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Epi-SiC Susceptor

Semicorex Epi-SiC Susceptor, a component engineered with meticulous attention to detail, is indispensable for cutting-edge semiconductor fabrication, especially in epitaxial applications. The Epi-SiC Susceptor’s design, which embodies precision and innovation, supports the epitaxial deposition of semiconductor materials on wafers, ensuring exceptional efficiency and dependability in performance. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.SiC Coating Component

Semicorex SiC Coating Component is an essential material designed to meet the demanding requirements of the SiC epitaxy process, a pivotal stage in semiconductor manufacturing. It plays a critical role in optimizing the growth environment for silicon carbide (SiC) crystals, contributing significantly to the quality and performance of the final product.*SiC Coated Plate

Semicorex SiC Coated Plate is a precision-engineered component made from graphite with a high-purity silicon carbide coating, designed for demanding epitaxial applications. Choose Semicorex for its industry-leading CVD coating technology, strict quality control, and proven reliability in semiconductor manufacturing environments.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.