- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China silicon carbide companies Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our enhancement strategy for silicon carbide companies,ball valve,silicon carbide for sale,silicon carbide ceramic,silicon carbide pump, In our efforts, we already have many shops in China and our products have won praise from customers worldwide. Welcome new and old customers to contact us for the future long term business relationships.

silicon carbide companies, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Hot Products

TaC Coating Graphite Cover

Semicorex TaC Coating Graphite Cover represents a cutting-edge solution in the realm of thermal applications for crystal growth and epitaxial (epi) processes. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Single-crystal Silicon Epi Susceptor

The Single-crystal Silicon Epi Susceptor is an essential component designed for Si-GaN epitaxy processes, which can be tailored to individualized specifications and preferences, providing a bespoke solution that aligns perfectly with specific requirements. Whether it entails modifications in dimensions or adjustments in coating thickness, we possess the capability to design and deliver a product that accommodates diverse process parameters, thereby optimizing performance for targeted applications. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.Wafer Carriers with SiC Coating

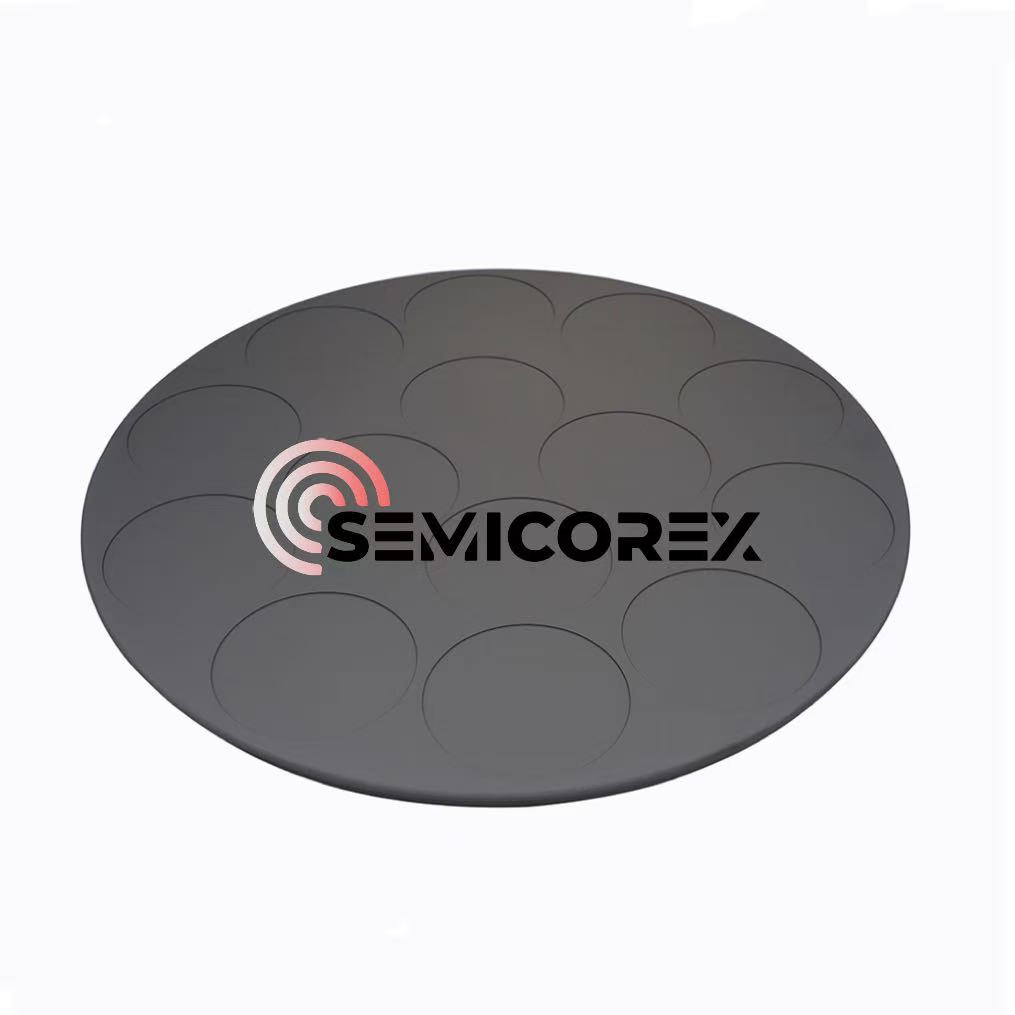

The Semicorex Wafer Carriers with SiC Coating, an integral part of the epitaxial growth system, is distinguished by its exceptional purity, resistance to extreme temperatures, and robust sealing properties, serving as tray that is essential for the support and heating of semiconductor wafers during the critical phase of epitaxial layer deposition, thereby optimizing the overall performance of the MOCVD process. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers with SiC Coating that fuse quality with cost-efficiency.8 inch EPI Bottom Ring

Semicorex 8 inch EPI Bottom Ring is a robust SiC coated graphite component essential for epitaxial wafer processing. Choose Semicorex for unmatched material purity, coating precision, and reliable performance in every production cycle.*Porous Alumina Chucks

Semicorex Porous Alumina Chucks are microporous black alumina vacuum fixture with 35–40% porosity, designed to provide uniform suction and safe wafer handling in semiconductor manufacturing. Choosing Semicorex means reliable ceramic engineering, superior material quality, and consistent performance that safeguard yield and process stability.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.