- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Quartz tank for cleaning wafers Manufacturers, Suppliers, Factory

We can constantly satisfy our respected customers with our good high quality, good price tag and good support due to we have been additional specialist and extra hard-working and do it in cost-effective way for Quartz tank for cleaning wafers,Glass tank cleaning,Quartz tank,Quartz glass tank,Quartz Reaction Tank, First company, we understand each other. Further more company, the trust is getting there. Our enterprise normally at your provider anytime.

Quartz tank for cleaning wafers, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. We hope to get inquiries from you and construct a long-term co-operation partnership.

Hot Products

Barrel Structure for Semiconductor Epitaxial Reactor

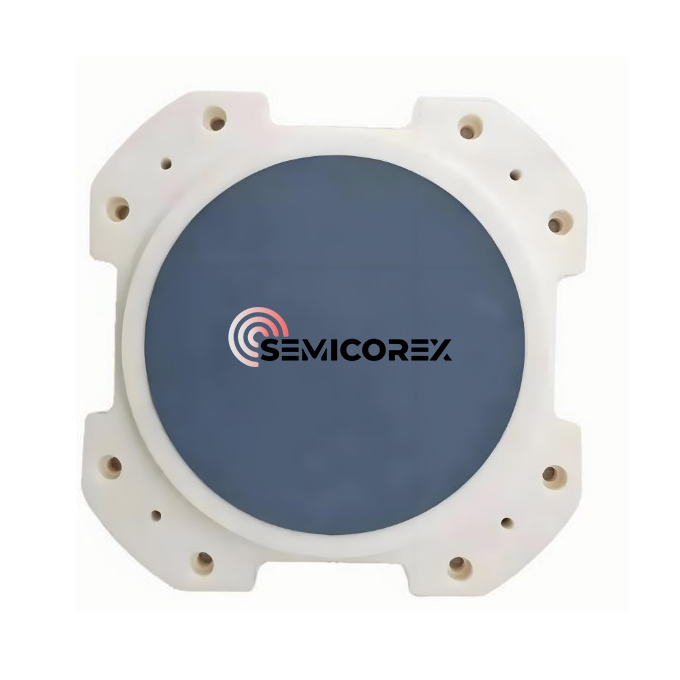

With its exceptional thermal conductivity and heat distribution properties, the Semicorex Barrel Structure for Semiconductor Epitaxial Reactor is the perfect choice for use in LPE processes and other semiconductor manufacturing applications. Its high-purity SiC coating provides superior protection in high-temperature and corrosive environments.ICP Etching Carrier Plate

Semicorex's ICP Etching Carrier Plate is the perfect solution for demanding wafer handling and thin film deposition processes. Our product provides superior heat and corrosion resistance, even thermal uniformity, and laminar gas flow patterns. With a clean and smooth surface, our carrier is perfect for handling pristine wafers.SiC Graphite RTP Carrier Plate for MOCVD

Semicorex SiC Graphite RTP Carrier Plate for MOCVD offers superior heat resistance and thermal uniformity, making it the perfect solution for semiconductor wafer processing applications. With a high-quality SiC coated graphite, this product is engineered to withstand the harshest deposition environment for epitaxial growth. The high thermal conductivity and excellent heat distribution properties ensure reliable performance for RTA, RTP, or harsh chemical cleaning.Tantalum Carbide Coating Chuck

Semicorex Tantalum Carbide Coating Chuck is a precision-engineered component designed for use in high-temperature and high-stress environments. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC ICP Etching Disk

Semicorex SiC ICP Etching Disk is not merely components; it's essential enabler of cutting-edge semiconductor manufacturing as the semiconductor industry continues its relentless pursuit of miniaturization and performance, the demand for advanced materials like SiC will only intensify. It ensures the precision, reliability, and performance required to power our technology-driven world.We at Semicorex are dedicated to manufacturing and supplying high-performance SiC ICP Etching Disk that fuses quality with cost-efficiency.**TaC Coated Tube

Semicorex TaC Coated Tube represents a pinnacle of material science, engineered to withstand the extreme conditions encountered in advanced semiconductor fabrication. Created by applying a dense, uniform layer of TaC onto a high-purity isotropic graphite substrate via Chemical Vapor Deposition (CVD), the TaC Coated Tube offers a compelling combination of properties that surpass conventional materials in demanding high-temperature and chemically aggressive environments.**