- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PBN composite Manufacturers, Suppliers, Factory

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for PBN composite,PBN,PG,PBN crucible,CVD PG, In a word, when you choose us, you choose a ideal existence. Welcome to visit our factory and welcome your get! For even further inquiries, remember to usually do not hesitate to make contact with us.

PBN composite, We've got been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We now have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We've been sincerely looking forward to establishing business relationships with friends from at home and abroad.

Hot Products

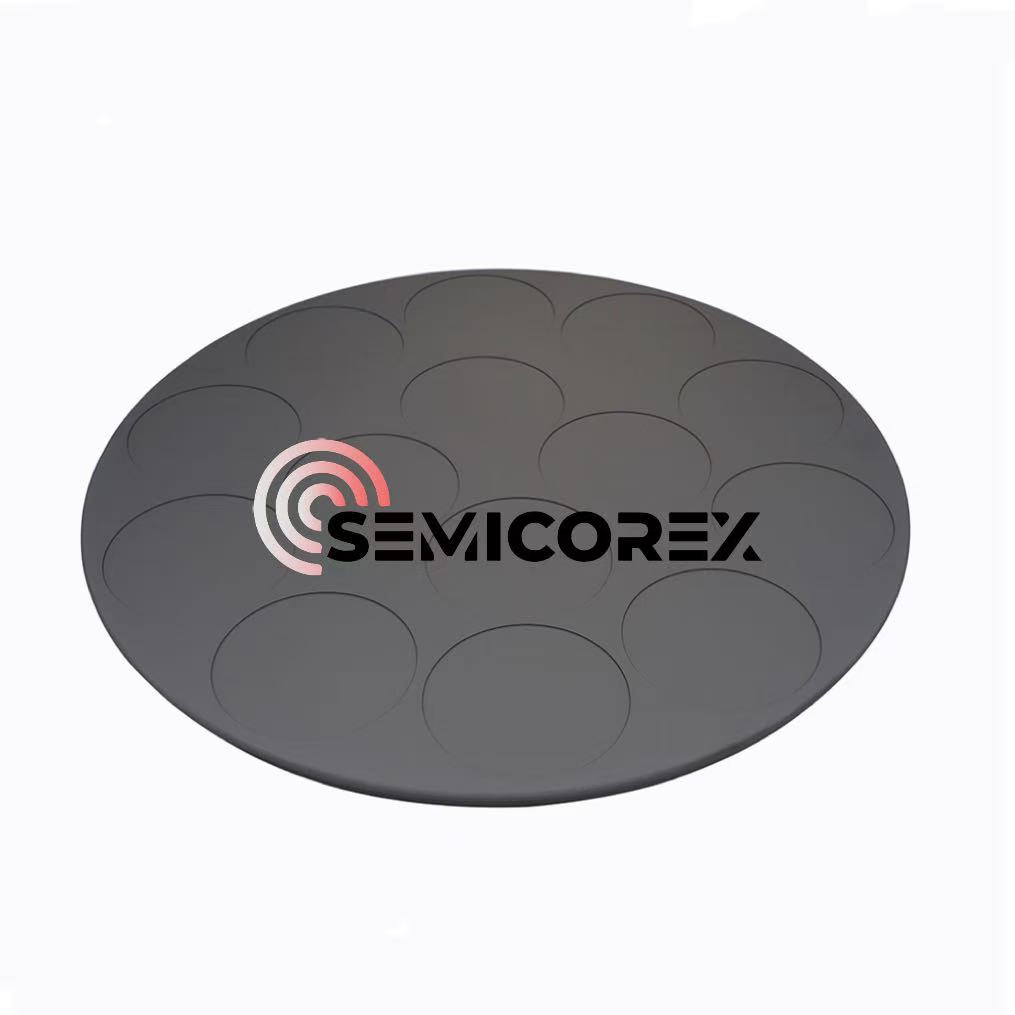

Silicon Epitaxy Susceptors

You can rest assured to buy Silicon Epitaxy Susceptors from our factory. Semicorex's Silicon Epitaxy Susceptor is a high-quality, high-purity product used in the semiconductor industry for epitaxial growth of the wafer chip. Our product has a superior coating technology that ensures the coating is present on all surfaces, preventing peeling off. The product is stable at high temperatures up to 1600°C, making it suitable for use in extreme environments.SiC Coating Graphite Substrate Wafer Carriers for MOCVD

You can rest assured to buy SiC Coating Graphite Substrate Wafer Carriers for MOCVD from our factory. At Semicorex, we are a large-scale manufacturer and supplier of SiC Coated Graphite Susceptor in China. Our product has a good price advantage and covers many of the European and American markets. We strive to provide our customers with high-quality products that meet their specific requirements. Our SiC Coating Graphite Substrate Wafer Carrier for MOCVD is an excellent choice for those looking for a high-performance carrier for their semiconductor manufacturing process.Second Half Parts for Lower Baffles in Epitaxial Process

Semicorex Second Half Parts for Lower Baffles in Epitaxial Process, meticulously engineered components designed to revolutionize the performance of your semiconductor devices. Specifically tailored for the intake system of LPE reactors, these semi-cylindrical fittings play a pivotal role in enhancing the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC Tantalum Carbide Coated Plate

Semicorex TaC Tantalum Carbide Coated Plate is a cutting-edge solution designed to meet the stringent demands of semiconductor manufacturing, particularly in the epitaxial (epi) processing stage. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC MOCVD Inner Segment

Semicorex SiC MOCVD Inner Segment is an essential consumable for metal-organic chemical vapor deposition (MOCVD) systems used in the production of silicon carbide (SiC) epitaxial wafers. It's precisely designed to withstand the demanding conditions of SiC epitaxy, ensuring optimal process performance and high-quality SiC epilayers.**SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.