- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Semi Silicon Wafer Manufacturers, Suppliers, Factory

Our solutions are commonly regarded and trusted by users and can fulfill continuously developing financial and social demands for Semi Silicon Wafer,Wafer Susceptor,Sic Wafer Susceptor,MOCVD Susceptor,Susceptor CVD, We've been hunting forward to forming effective business marriage with new clients from the near upcoming!

Semi Silicon Wafer Lamp, Due to the stability of our products, timely supply and our sincere service, we are able to sell our goods not only over the domestic market, but also exported to countries and regions, including the Middle East, Asia, Europe and other countries and regions. At the same time, we also undertake OEM and ODM orders. We'll do our best to serve your company, and establish a successful and friendly cooperation with you.

Hot Products

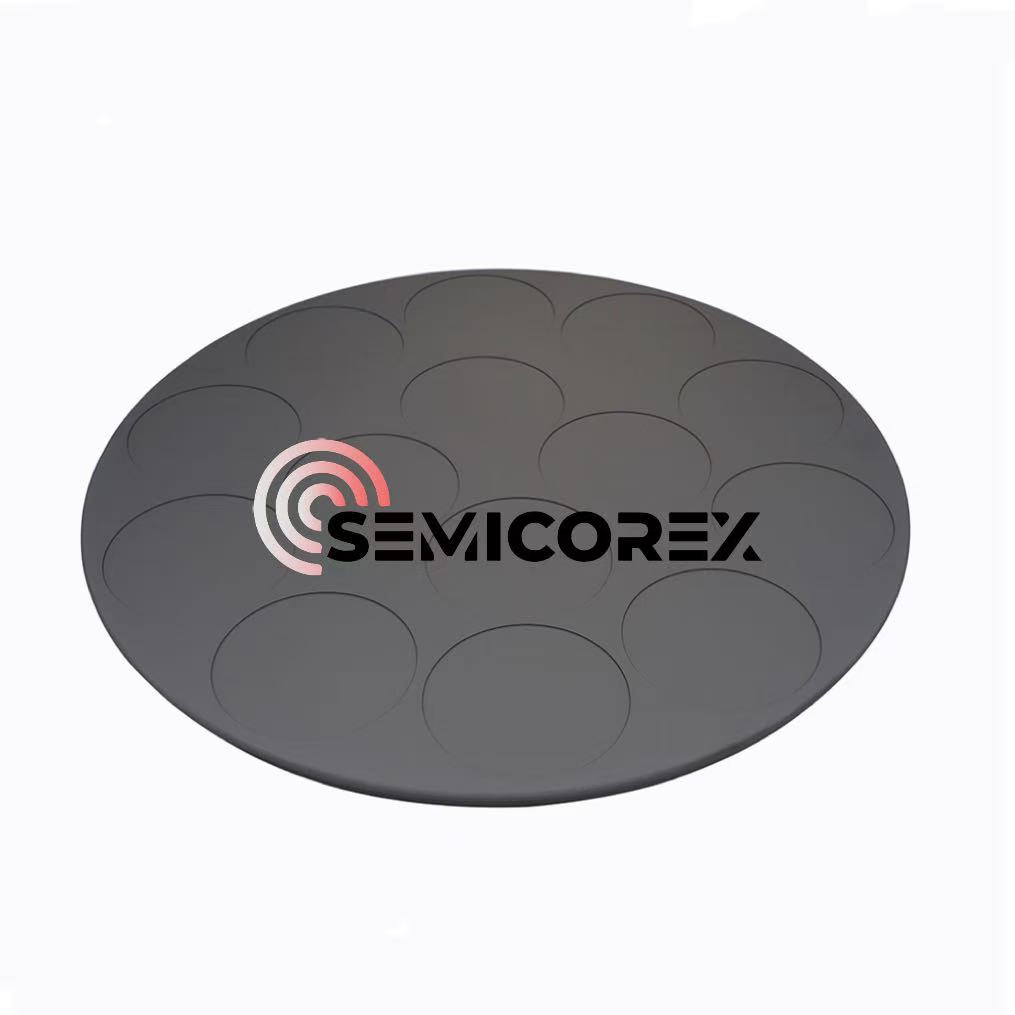

ICP Etching Carrier Plate

Semicorex's ICP Etching Carrier Plate is the perfect solution for demanding wafer handling and thin film deposition processes. Our product provides superior heat and corrosion resistance, even thermal uniformity, and laminar gas flow patterns. With a clean and smooth surface, our carrier is perfect for handling pristine wafers.SiC Susceptor for MOCVD

Semicorex is a leading manufacturer and supplier of SiC Susceptor for MOCVD. Our product is specially designed to cater to the needs of the semiconductor industry in growing the epitaxial layer on the wafer chip. The product is used as the center plate in MOCVD, with a gear or ring-shaped design. It has high heat and corrosion resistance, making it ideal for use in extreme environments.Deep-UV LED Epitaxial Susceptor

Semicorex is a large-scale manufacturer and supplier of Silicon Carbide Coated Graphite Susceptor in China. We have been manufacturer and supplier of Deep-UV LED Epitaxial Susceptor for many years. Our products have a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.TaC Coated Rings

As the professional manufacture, we would like to provide you TaC Coated Rings. Introducing the CVD Tac Coated Ring, a state-of-the-art solution for semiconductor equipment. This cutting-edge product boasts an advanced chemical vapor deposition (CVD) coating that provides exceptional durability and resistance to wear and tear.MOCVD Susceptors

Semicorex’s MOCVD Susceptors epitomize the pinnacle of craftsmanship, endurance, and reliability for intricate graphite epitaxy and precise wafer handling tasks. These susceptors are renowned for their high density, exceptional flatness, and superior thermal control, making them the premier choice for demanding manufacturing environments. We at Semicorex are dedicated to manufacturing and supplying high-performance MOCVD Susceptors that fuse quality with cost-efficiency.SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.