- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

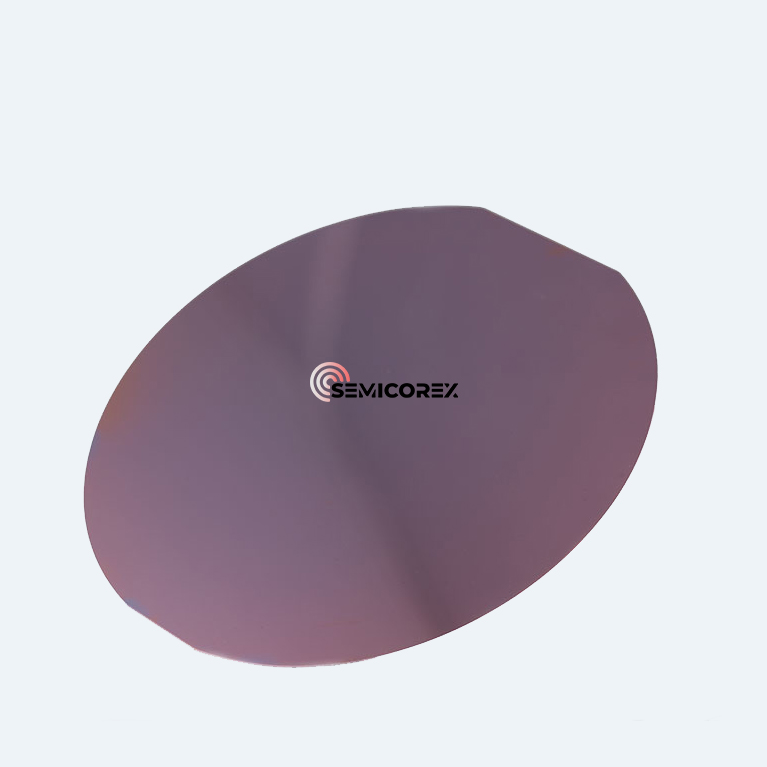

China 150mm silicon wafers Manufacturers, Suppliers, Factory

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for 150mm silicon wafers,Si wafer,Silicon wafer,silicon substrate,silicon on insulator, We have been prepared to offer you the top suggestions on the designs of one's orders in a professional way if you need. During the meantime, we retain on developing new technologies and building new designs so as for making you ahead within the line of this business.

150mm silicon wafers, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Hot Products

ICP Plasma Etching Tray

Semicorex's ICP Plasma Etching Tray is engineered specifically for high-temperature wafer handling processes such as epitaxy and MOCVD. With a stable, high-temperature oxidation resistance of up to 1600°C, our carriers provide even thermal profiles, laminar gas flow patterns, and prevent contamination or impurities diffusion.Wafer Carriers with SiC Coating

The Semicorex Wafer Carriers with SiC Coating, an integral part of the epitaxial growth system, is distinguished by its exceptional purity, resistance to extreme temperatures, and robust sealing properties, serving as tray that is essential for the support and heating of semiconductor wafers during the critical phase of epitaxial layer deposition, thereby optimizing the overall performance of the MOCVD process. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers with SiC Coating that fuse quality with cost-efficiency.Epitaxy Wafer Carrier

Semicorex Epitaxy Wafer Carrier provides a highly reliable solution for Epitaxy applications.The advanced materials and coating technology ensure that these carriers deliver outstanding performance, reducing operational costs and downtime due to maintenance or replacement.**6'' Wafer Carrier for Aixtron G5

Semicorex 6'' Wafer Carrier for Aixtron G5 offers a multitude of advantages for use in Aixtron G5 equipment, particularly in high-temperature and high-precision semiconductor manufacturing processes.**Etching Wafer Carrier

Semicorex Etching Wafer Carrier with CVD SiC Coating is an advanced, high-performance solution tailored for demanding semiconductor etching applications. Its superior thermal stability, chemical resistance, and mechanical durability make it an essential component in modern wafer fabrication, ensuring high efficiency, reliability, and cost-effectiveness for semiconductor manufacturers worldwide.*8 inch EPI Bottom Ring

Semicorex 8 inch EPI Bottom Ring is a robust SiC coated graphite component essential for epitaxial wafer processing. Choose Semicorex for unmatched material purity, coating precision, and reliable performance in every production cycle.*