- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

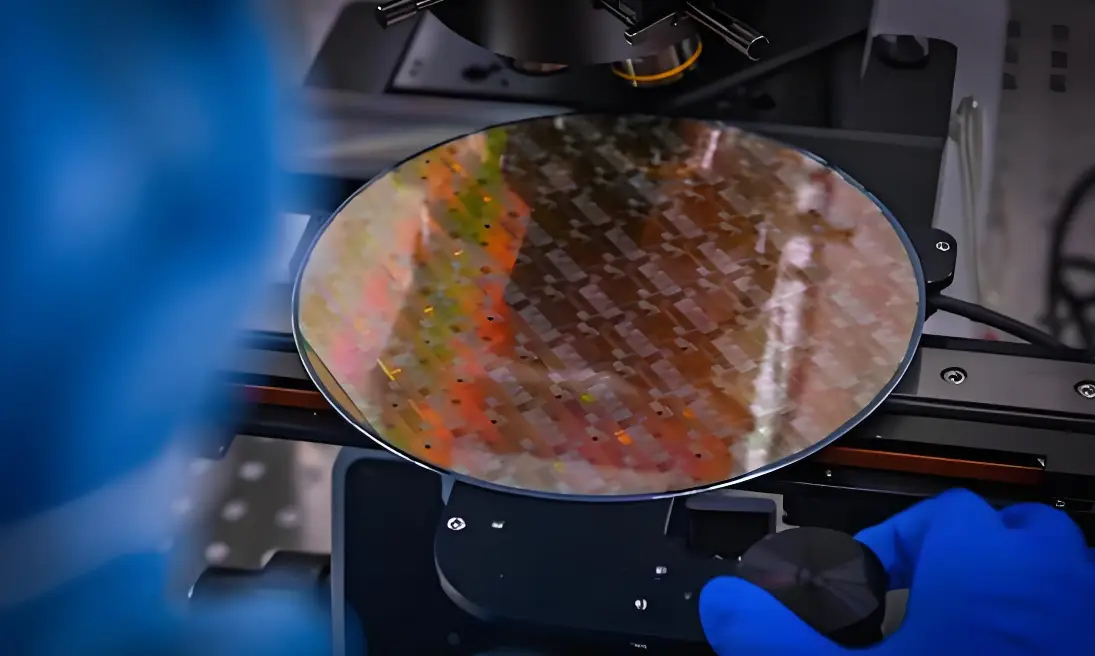

What is The Semiconductor Wafer Cleaning?

Wafer cleaning refers to the process of removing particulate contaminants, organic contaminants, metal contaminants, and natural oxide layers from the wafer surface using physical or chemical methods before semiconductor processes such as oxidation, photolithography, epitaxy, diffusion, and wire eva......

Read MorePreparation Process of SiC Ceramics

Silicon carbide ceramics are among the most widely used materials in structural ceramics. Due to their relatively low thermal expansion, high specific strength, high thermal conductivity and hardness, wear resistance and corrosion resistance, and most importantly, their ability to maintain good perf......

Read MoreWhat are First-generation, Second-generation, Third-generation, and Fourth-generation semiconductor materials?

Semiconductor materials are the materials with electrical conductivity between conductors and insulators at room temperature, which are widely used in fields like integrated circuits, communications, energy and optoelectronics. With development of technology, semiconductor materials have evolved fro......

Read MoreWhat is the Function of Focus Rings?

Focus rings are the essential components to ensure the uniformity and stability of the semiconductor etching processes. Through precise control of electric and thermal fields, focus rings can concentrate plasma on the wafer surface, ensuring consistent etching results across all locations on the waf......

Read MoreSiC Ceramic Mechanical Seals

Silicon carbide has good chemical stability and can withstand various highly corrosive acidic and alkaline media, making it suitable for mechanical seals in corrosive media. Corrosive wear is a major form of failure for friction pair materials. Hot-pressed sintered silicon carbide forms a protective......

Read MoreWhat is the particle defects?

Particle defects refer to the tiny particulate inclusions inside or on the semiconductor wafers. They can damage the structural integrity of semiconductor devices and cause electrical faults such as short circuits and open circuits. Since these problems caused by particle defects can seriously af......

Read More