- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

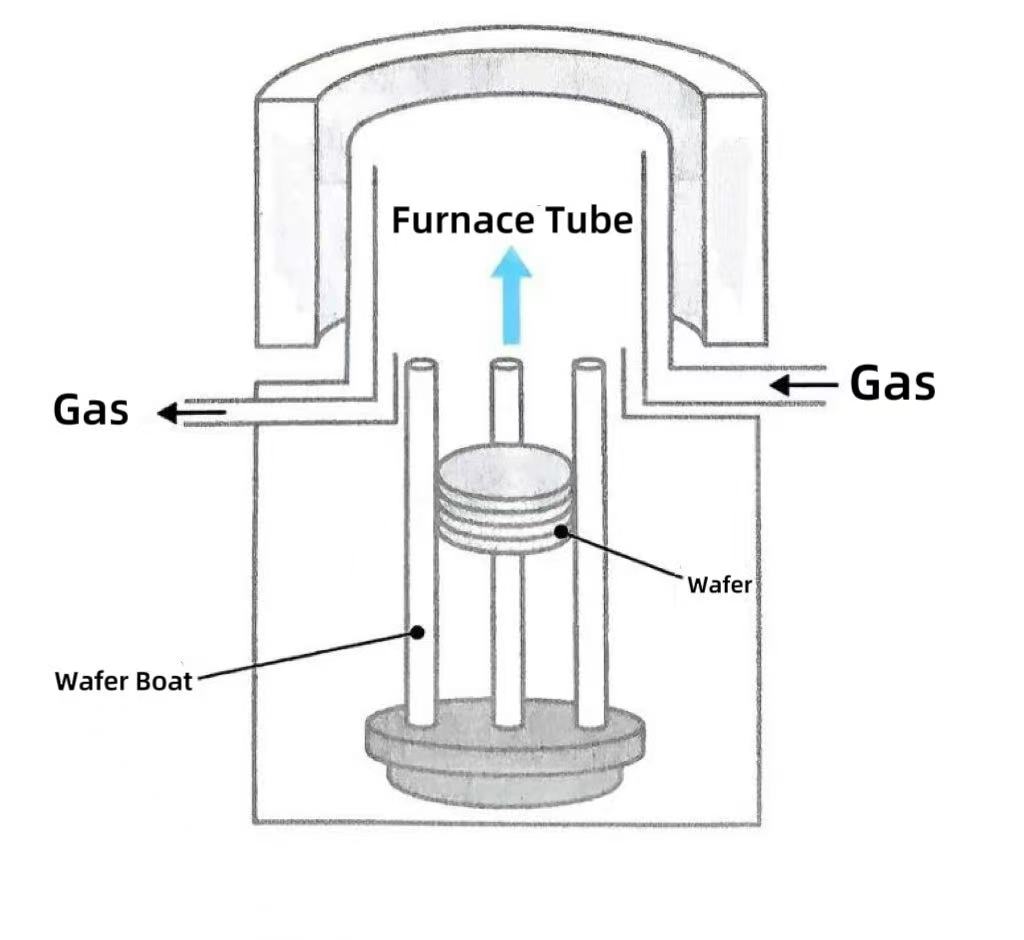

Why have vertical furnaces become the mainstream choice?

Vertical furnaces are the vertically placed high-temperature heating devices specially designed for the heat treatment of semiconductor manufacturing. The complete vertical furnace system is composed of the high-temperature resistant furnace tube, the heating element, the temperature control system,......

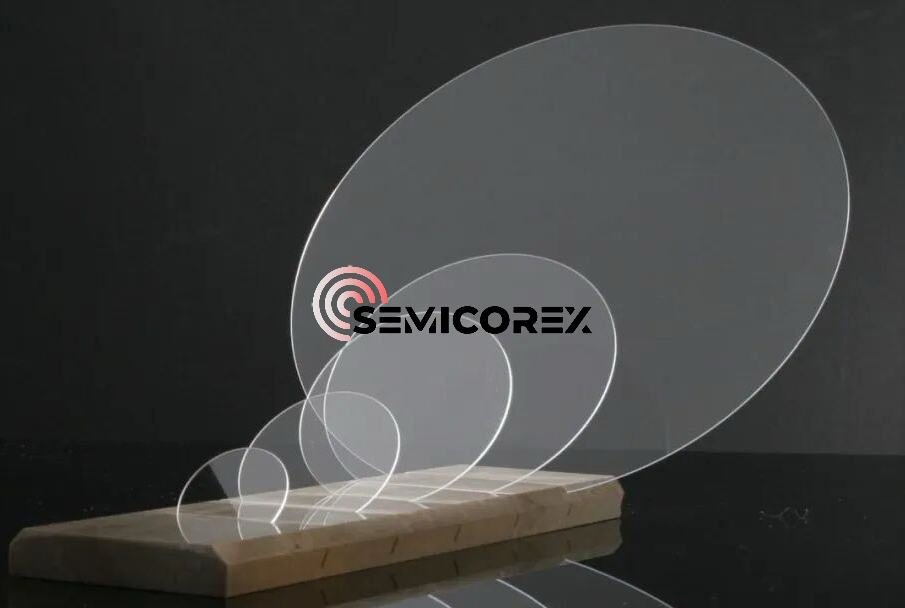

Read MoreHigh-purity Fused Quartz Crucible for Single-crystal Pulling

Currently, monocrystalline silicon is produced using polycrystalline silicon as a raw material and the Czochralski method. In monocrystalline silicon production, the quartz crucible is a critical material for melting silicon and crystal growth, and it has a direct and significant impact on the produ......

Read MoreHow is the stress generated in semiconductor quartz products?

Quartz is the primary material in high-end fields such as semiconductors and optical instruments. However, the existence of stress is like a "time bomb", which can damage the physical and chemical properties of quartz, affecting the usage effect and lifespan of its final products. Therefore, thoroug......

Read MoreSilicon, Silicon Carbide and Gallium Nitride

Behind the common used digital products and high-tech electric vehicles, 5G base station, there are 3 core semiconductor materials: Silicon, Silicon Carbide and Gallium Nitride driving the industry. They are not alternative for each other, they are the experts in a team, and have the irreplaceable e......

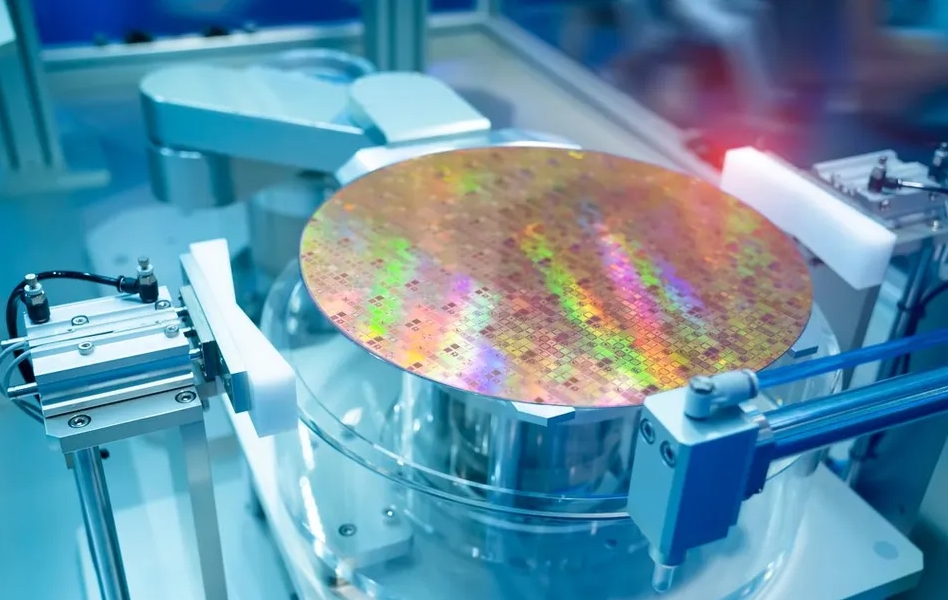

Read MoreWhat is the notch on wafers?

The wafer notch is a V-shaped or U-shaped groove on the edge of a semiconductor wafer. Far from being a defect incurred during the manufacturing process, it is the critical structural marker that was intentionally designed, whose core function lies in enabling precise positioning and orientation ide......

Read More