- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

How Does TaC Coating Protect Graphite Components In Semiconductors

That's where the game-changing innovation of TaC Coating enters the picture, and why our advanced solutions at Semicorex are engineered to directly address your most persistent production pain points. Graphite is fantastic for its thermal properties, but without a robust shield, it simply cannot wit......

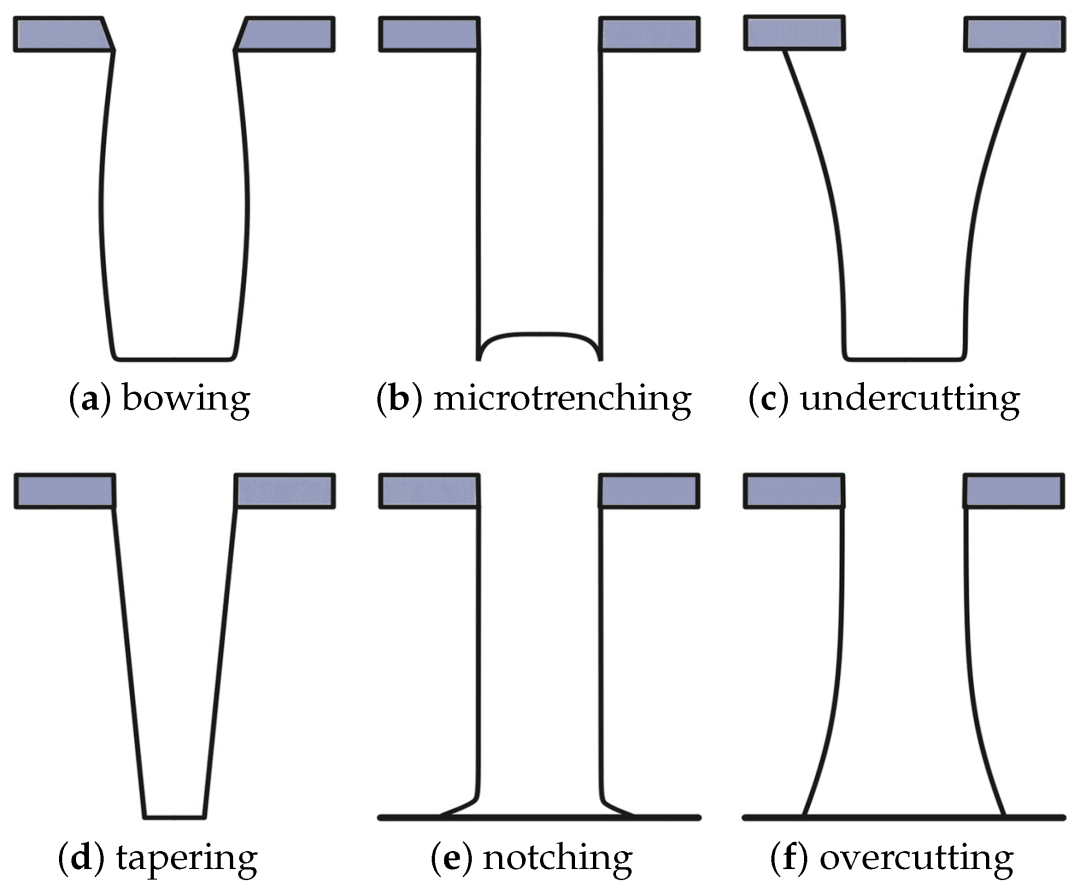

Read MoreEtching and Etched Morphology

In the semiconductor chip manufacturing process, we are like building a skyscraper on a grain of rice. The lithography machine is like a city planner, using "light" to draw the blueprint for the building on the wafer; while etching is like a sculptor with precision tools, responsible for accurately ......

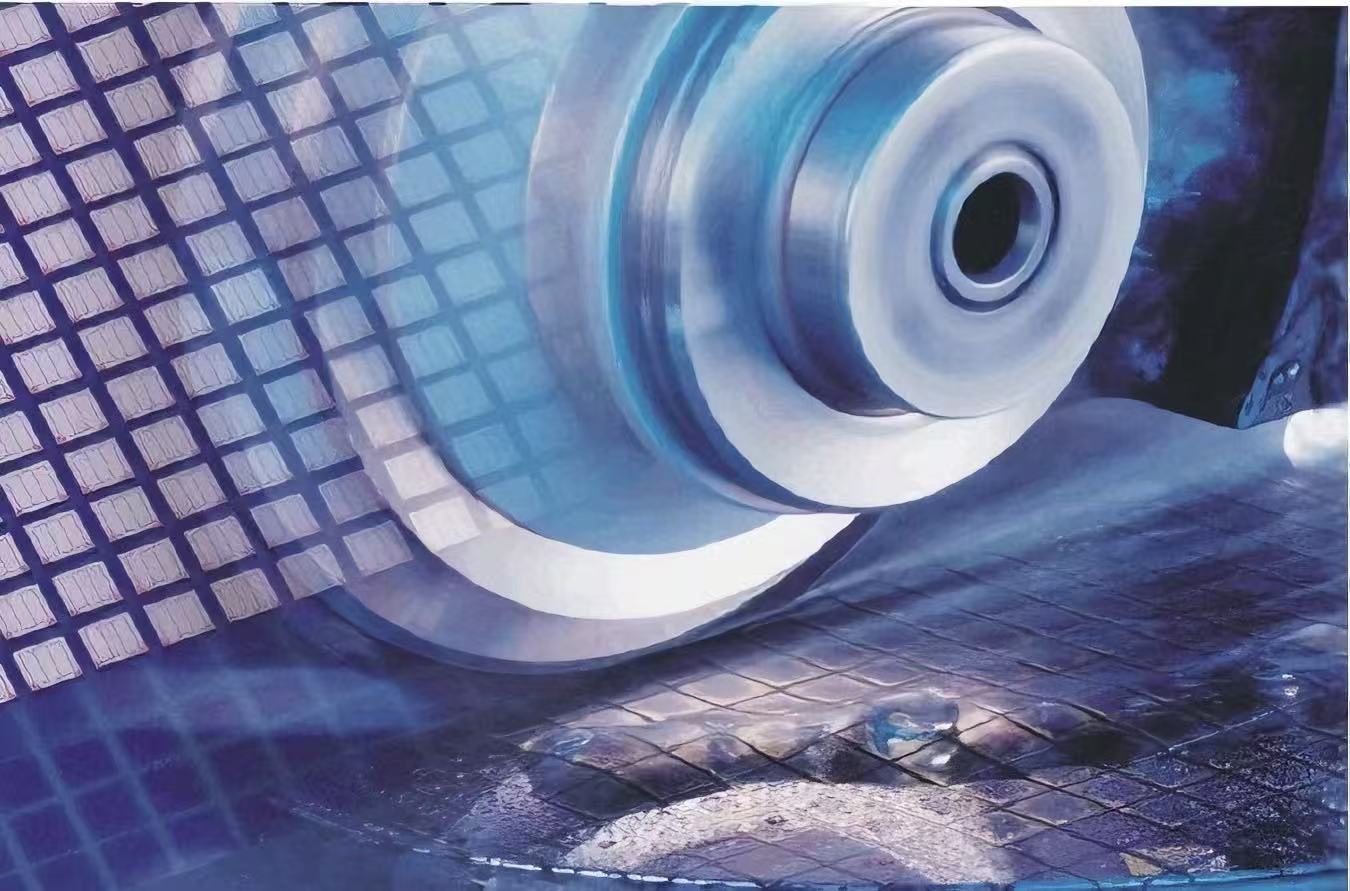

Read MoreWhat are dishing and erosion in the CMP process?

Chemical mechanical polishing (CMP), which combines chemical corrosion and mechanical polishing to remove surface imperfections, is the significant semiconductor process for achieving overall planarization of the wafer surface. CMP results in two surface defects, dishing and erosion, which significa......

Read MoreWhat is Self-lubricating Bushing

Self-lubricating bushing, is a general name for a large category of products - the bushings that can achieve lubrication without adding extra lubricant, also the self-lubricating bearings include oil-impregnated bushings and composite bushings. The core principle is to automatically release the lubr......

Read MoreWhat is Silicon Epitaxy Process?

Silicon epitaxy is a primary fabrication process for integrated circuits. It allows IC devices to be fabricated on lightly doped epitaxial layers with heavily doped buried layers, while also forming grown PN junctions, thus solving the isolation problem of ICs. Silicon epitaxial wafers are also a pr......

Read More