- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Silicon Nitride Tube

Semicorex Silicon Nitride Tube is made by high performance Si3N4 material, the performance of strength, hardness, thermal conductivity is credible. Semicorex is committed to deliver qualified products worldwide.*

Send Inquiry

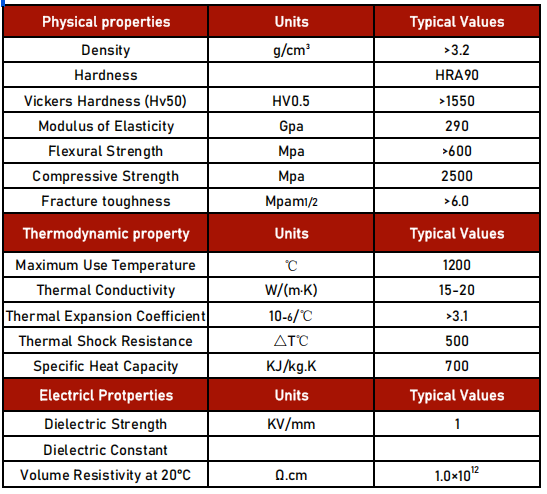

Semicorex Silicon Nitride Tube is a precision machined part, it has great performance on physical properties. Silicon nitride ceramics have well-known excellent physicochemical properties, primarily characterized by high hardness, high strength, low coefficient of thermal expansion, and excellent thermal stability. Silicon nitride with a density of approximately 3.2 g/cm³, a Vickers hardness of 1400-1600, and a flexural strength exceeding 600 MPa, can resistant to deformation under mechanical loads. And silicon nitride tube has an extremely low CTE, approximately 3.1 × 10⁻⁶ Kelvin, and a thermal conductivity between 15-20 W/m·Kelvin. This property is mainly shown when it is in high temperature environment, the dimensional fluctuations will be minimal when the temperature rapidly changes, such as a sudden rise from room temperature to 1000℃ or rapid cooling, preventing cracks or deformation caused by thermal stress. Chemically, silicon nitride tube possesses excellent corrosion resistance and oxidation resistance. It does not readily react with acids, alkalis, or oxygen at high temperatures and can operate stably for extended periods above 1200 degrees Celsius, thanks to its stable covalent bond structure and the protective oxide layer formed on its surface. These properties collectively ensure the high dimensional stability of silicon nitride tubes in thermal cycling environments, thus extending their service life.

Silicon Nitride tube is produced in three basic stages - raw material preparation, sintering and final machining. The production of silicon nitride powder through either reaction sintering or hot pressing processes requires high purity of silicon powder and nitrogen gas, to ensure that the purity is maintained and that particle size is uniform. Semicorex uses great ball milling and a purification furnace to ensure quality assurance of the powder and particle size uniformity.

There are several different forming process type, and typically utilises injection molding, isostatic pressing or extrusion molding. For the large size of tubes, the isostatic pressing is required. It can guarantee the tube with high density and structural stability. The high temperature and pressure sintering step is the most important stage, it is typically performed between 1700-1800 degrees Celsius in a gas pressure sintering or hot isostatic pressing method. Sintering can densify the particles, reduces porosity, increases mechanical strength, and increases thermal stability. And the final stage combines grinding, polishing and inspection to meet the required dimensional tolerances and surface finish requirements.

Silicon nitride tubes are prominent in industrial applications due to their high-temperature resistance and dimensional stability in severe environments. Silicon nitride ceramic tubes are often used in semiconductor processing equipment and high-temperature furnace tubes. In this case, silicon nitride ceramic tubes must maintain a dimensional accuracy while preventing contamination or malfunction from thermal shock and control or equipment instability. In the aerospace industry, silicon nitride ceramic tubes are commonly used in engine components, thermal protection systems, and other applications with extreme temperature variations - where safety and reliability are critical. Likewise, in the automotive industry, they can make up turbochargers and exhaust systems which improve fuel efficiency and emissions control. In heat treatment furnaces and solar photovoltaic manufacturing equipment, silicon nitride ceramic tubes serve as a high-temperature element - increasing the life of the heat-dissipating equipment, and reducing downtime and maintenance costs.