- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

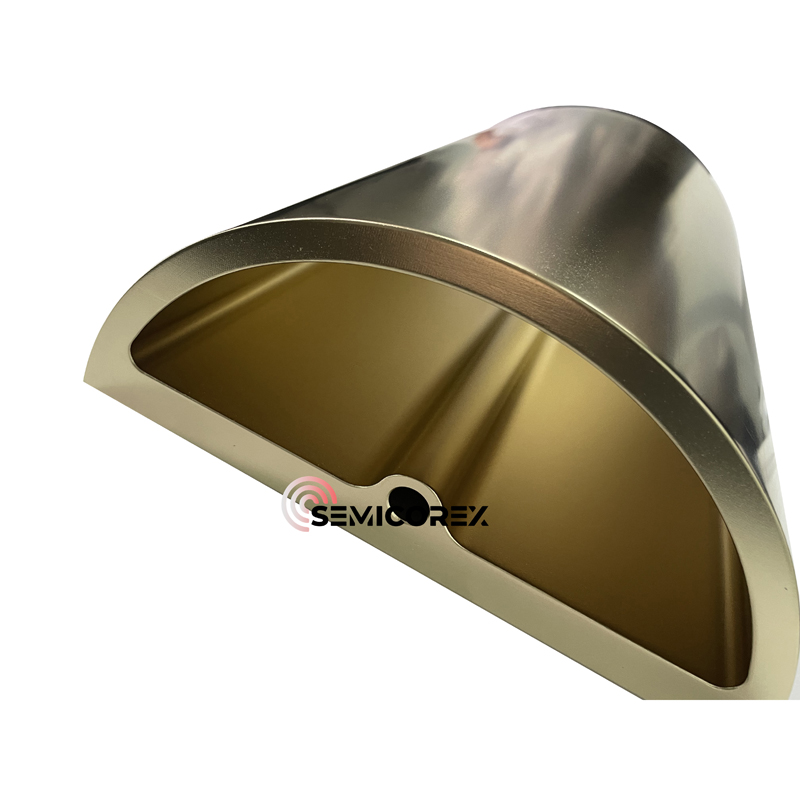

China Susceptor for Holding Semiconductor Wafers Manufacturers, Suppliers, Factory

It adheres to the tenet ""Honest, industrious, enterprising, innovative"" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Susceptor for Holding Semiconductor Wafers,Etch Carrier(ICP/PSS),ICP Carrier,Graphite Components,Carbide-Coated Graphite, Welcome your enquiry, most effective service will likely be provided with full heart.

Susceptor for Holding Semiconductor Wafers, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

Hot Products

Silicon Carbide-Coated Graphite Barrel

The Semicorex Silicon Carbide-Coated Graphite Barrel is the perfect choice for semiconductor manufacturing applications that require high heat and corrosion resistance. Its exceptional thermal conductivity and heat distribution properties make it ideal for use in LPE processes and other high-temperature environments.SiC Coated RTP Carrier Plate for Epitaxial Growth

Semicorex SiC Coated RTP Carrier Plate for Epitaxial Growth is the perfect solution for semiconductor wafer processing applications. With its high-quality carbon graphite susceptors and quartz crucibles processed by MOCVD on the surface of graphite, ceramics, etc., this product is ideal for wafer handling and epitaxial growth processing. The SiC coated carrier ensures high thermal conductivity and excellent heat distribution properties, making it a reliable choice for RTA, RTP, or harsh chemical cleaning.Susceptor Disc

The Semicorex Susceptor Disc is an indispensable tool in Metal-Organic Chemical Vapor Deposition (MOCVD), specifically engineered for supporting and heating semiconductor wafers during the critical process of epitaxial layer deposition. The Susceptor Disc is instrumental in the manufacturing of semiconductor devices, where precise layer growth is paramount. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.Wafer Carrier for MOCVD

the Semicorex Wafer Carrier for MOCVD, Crafted for the precise needs of Metal Organic Chemical Vapor Deposition (MOCVD), emerges as an indispensable tool in the processing of single-crystal Si or SiC for high-scale integrated circuits. The Wafer Carrier for MOCVD composition boasts unparalleled purity, resistance to elevated temperatures and corrosive environments, and superior sealing properties to maintain a pristine atmosphere. We at Semicorex are dedicated to manufacturing and supplying high-performance Wafer Carriers for MOCVD that fuse quality with cost-efficiency.Epitaxial Susceptor

Semicorex Epitaxial Susceptor with SiC coating is designed to support and hold SiC wafers during the epitaxial growth process, ensuring precision and uniformity in semiconductor manufacturing. Choose Semicorex for its high-quality, durable, and customizable products that meet the rigorous demands of advanced semiconductor applications.*LPE Part

Semicorex LPE Part is a SiC-coated component specifically designed for the SiC epitaxy process, offering exceptional thermal stability and chemical resistance to ensure efficient operation in high-temperature and harsh environments. By choosing Semicorex products, you benefit from high-precision, long-lasting custom solutions that optimize the SiC epitaxy growth process and enhance production efficiency.*