- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China SiC Coating Substrate Manufacturers, Suppliers, Factory

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for SiC Coating Substrate,Silicon Carbide-Coated,SiC Graphite Supplies Susceptors,Graphite Susceptors for Silicon,SiC Coating for GaN Epitaxy, We warmly welcome all intrigued customers to speak to us for additional information and facts.

SiC Coating Substrate, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Hot Products

Liquid Phase Epitaxy (LPE) Reactor System

Semicorex Liquid Phase Epitaxy (LPE) Reactor System is an innovative product that offers excellent thermal performance, even thermal profile, and superior coating adhesion. Its high purity, high-temperature oxidation resistance, and corrosion resistance make it an ideal choice for use in the semiconductor industry. Its customizable options and cost-effectiveness make it a highly competitive product in the market.TaC Coated Graphite Susceptor

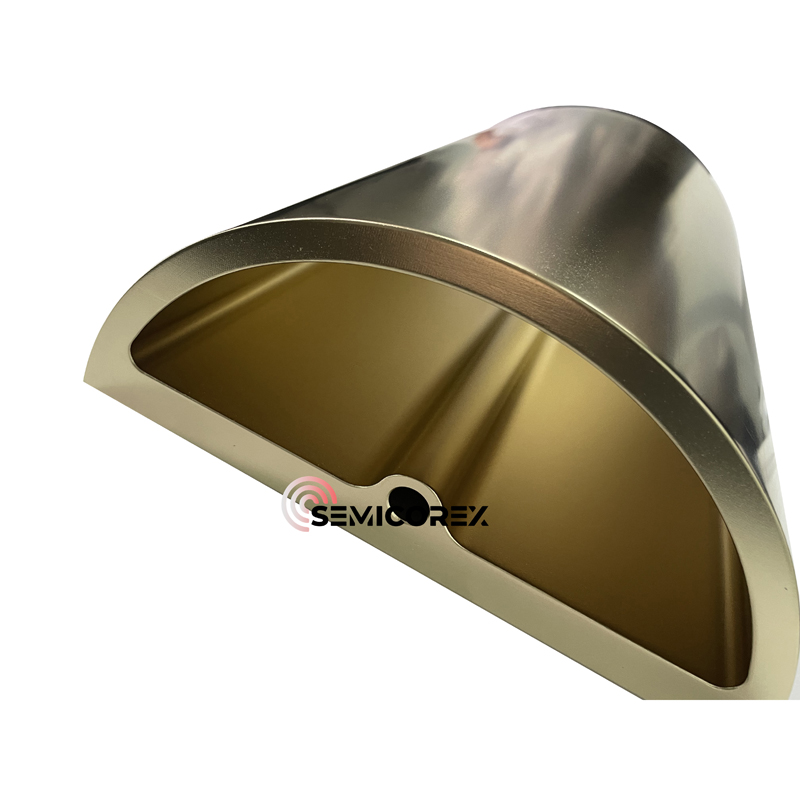

Semicorex cutting-edge TaC Coated Graphite Susceptor, a revolutionary component designed to elevate your wafer epitaxial process to new heights of efficiency and precision. Crafted with unparalleled expertise and utilizing state-of-the-art technology, Semicorex TaC Coated Graphite Susceptor is engineered to meet the exacting demands of semiconductor manufacturing.Tantalum Carbide Coating Halfmoon Part

Semicorex Tantalum Carbide Coating Halfmoon Part is a highly specialized component designed for use in the epitaxial deposition process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC Coated Tube

Semicorex TaC Coated Tube represents a pinnacle of material science, engineered to withstand the extreme conditions encountered in advanced semiconductor fabrication. Created by applying a dense, uniform layer of TaC onto a high-purity isotropic graphite substrate via Chemical Vapor Deposition (CVD), the TaC Coated Tube offers a compelling combination of properties that surpass conventional materials in demanding high-temperature and chemically aggressive environments.**SiC Coating Heater

The CVD SiC coating of Semicorex SiC Coating Heater offers superior performance in protecting heating elements from the harsh, corrosive, and reactive environments often encountered in processes such as Metal-Organic Chemical Vapor Deposition (MOCVD) and Epitaxial Growth.**Porous Alumina Chucks

Semicorex Porous Alumina Chucks are microporous black alumina vacuum fixture with 35–40% porosity, designed to provide uniform suction and safe wafer handling in semiconductor manufacturing. Choosing Semicorex means reliable ceramic engineering, superior material quality, and consistent performance that safeguard yield and process stability.*