- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China ICP Etching Tray Manufacturers, Suppliers, Factory

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for ICP Etching Tray,Etch Carrier(ICP/PSS),ICP Carrier Plate,ICP Plasma Etch System,RIE/ICP Etch System, Our staff members are goal to provides solutions with high performance cost ratio to our prospects, as well as target for all of us is always to satisfy our consumers from everywhere in the globe.

ICP Etching Tray, Since our establishment, we keep on improving our products and solutions and customer service. We have been able to supply you with a wide range of high quality hair items at competitive prices. Also we can produce different hair merchandise according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

Hot Products

Deep-UV LED Epitaxial Susceptor

Semicorex is a large-scale manufacturer and supplier of Silicon Carbide Coated Graphite Susceptor in China. We have been manufacturer and supplier of Deep-UV LED Epitaxial Susceptor for many years. Our products have a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.TaC Coating Ring

Semicorex TaC Coating Ring stands as a pivotal component in the realm of monocrystal growth within the thermal field. Crafted with precision and innovation, this specialized guide ring plays a crucial role in the intricate process of monocrystalline material production. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Disc Susceptor

Semicorex introduces its SiC Disc Susceptor, designed to elevate the performance of Epitaxy, Metal-Organic Chemical Vapor Deposition (MOCVD), and Rapid Thermal Processing (RTP) equipment. The meticulously engineered SiC Disc Susceptor provides with properties that guarantee superior performance, durability, and efficiency in high-temperature and vacuum environments.**SiC Coated Wafer Carriers

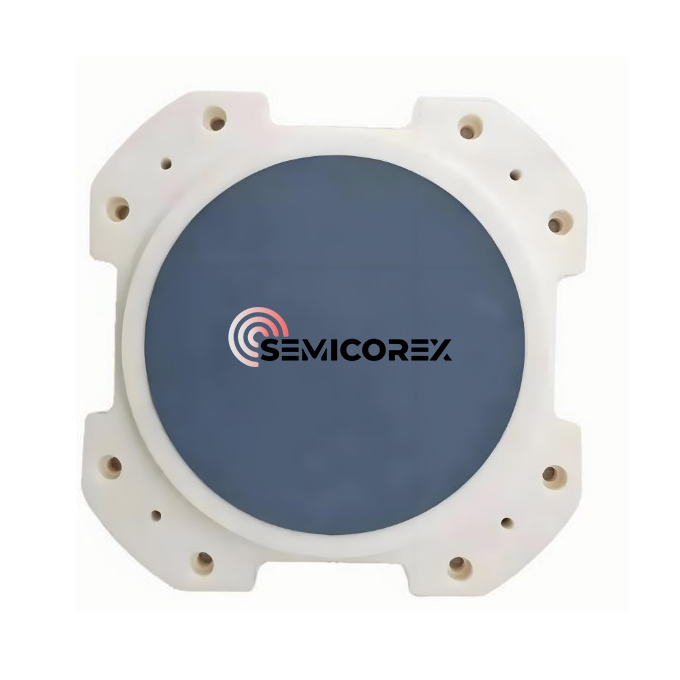

Semicorex SiC Coated Wafer Carriers are high-purity graphite susceptors coated with CVD silicon carbide, designed for optimal wafer support during high-temperature semiconductor processes. Choose Semicorex for unmatched coating quality, precision manufacturing, and proven reliability trusted by leading semiconductor fabs worldwide.*Al2O3 Vacuum Chucks

Semicorex Al2O3 Vacuum Chucks are microporous ceramic adsorption fixture made from black alumina with a porosity of 35–40%, specifically designed for wafer handling in semiconductor applications. Choosing Semicorex means benefiting from advanced ceramic technology, precision engineering, and reliable product quality that ensure stable performance in demanding cleanroom environments.*SiC-coated Graphite MOCVD Susceptors

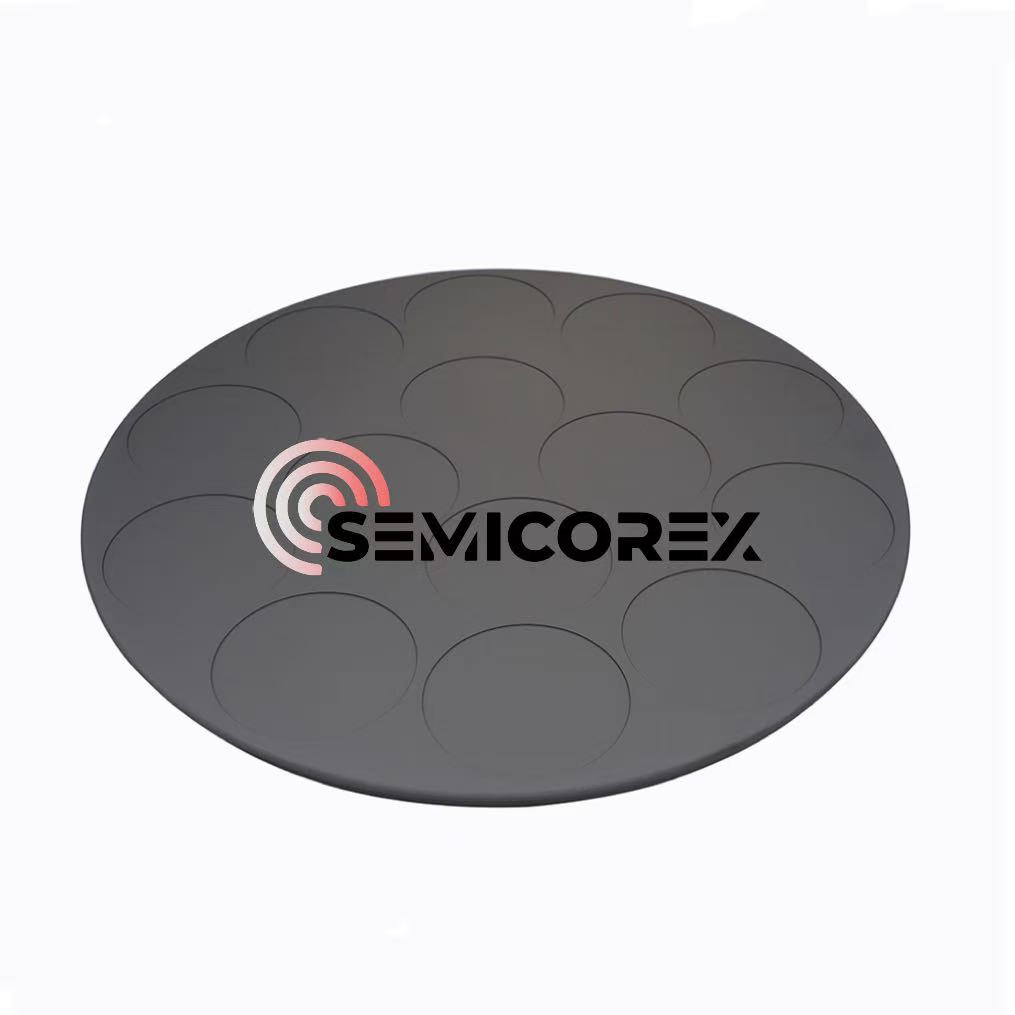

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.