- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China czochralski crystal pulling method Manufacturers, Suppliers, Factory

We've been also focusing on improving upon the stuff management and QC program to make sure that we could hold fantastic gain in the fiercely-competitive enterprise for czochralski crystal pulling method,graphite crucible,graphite felt insulation,carbon graphite insulation,graphite heating element, Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

czochralski crystal pulling method, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

Hot Products

High-Temperature SiC-Coated Barrel Susceptor

When it comes to semiconductor manufacturing, the Semicorex High-Temperature SiC-Coated Barrel Susceptor is the top choice for superior performance and reliability. Its high-quality SiC coating and exceptional thermal conductivity make it ideal for use in even the most demanding high-temperature and corrosive environments.Silicon Epitaxy Susceptors

You can rest assured to buy Silicon Epitaxy Susceptors from our factory. Semicorex's Silicon Epitaxy Susceptor is a high-quality, high-purity product used in the semiconductor industry for epitaxial growth of the wafer chip. Our product has a superior coating technology that ensures the coating is present on all surfaces, preventing peeling off. The product is stable at high temperatures up to 1600°C, making it suitable for use in extreme environments.SiC Coated Graphite Base Susceptors for MOCVD

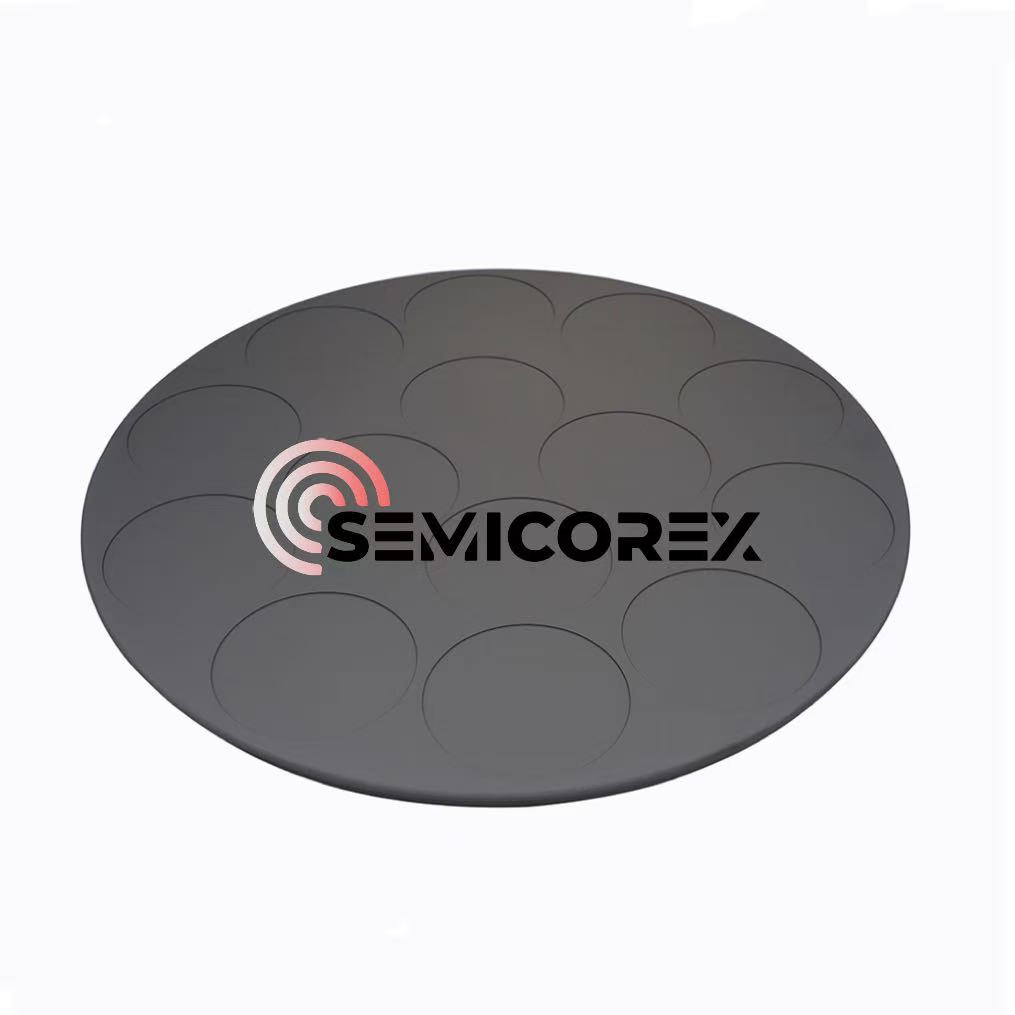

Semicorex SiC Coated Graphite Base Susceptors for MOCVD are superior quality carriers used in the semiconductor industry. Our product is designed with high-quality silicon carbide that provide excellent performance and long-lasting durability. This carrier is ideal for use in the process of growing an epitaxial layer on the wafer chip.SiC Coated Ring

Semicorex SiC Coated Ring is a crucial component in the semiconductor epitaxial growth process, designed to meet the demanding requirements of modern semiconductor manufacturing. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Inlet Rings

Semicorex SiC Inlet Rings are high-performance silicon carbide components engineered for semiconductor processing equipment, offering exceptional thermal stability, chemical resistance, and precision machining. Choosing Semicorex means gaining access to reliable, customized, and contamination-free solutions trusted by leading semiconductor manufacturers.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.