- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China MOCVD Chamber Lids Manufacturers, Suppliers, Factory

Our solutions are broadly acknowledged and dependable by users and may meet consistently developing economic and social requires for MOCVD Chamber Lids,MOCVD Ceiling Plate,MOCVD Cover Plate,Silicon Carbide Ceramic Lid,Graphite Ceiling, Thanks for taking your useful time to go to us and look ahead to have a nice cooperation with you.

MOCVD Chamber Lids, We insist on "Quality First, Reputation First and Customer First". We are committed to providing high-quality items and good after-sales services. Up to now, our solutions have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of "Credit, Customer and Quality", we expect cooperation with people in all walks of life for mutual benefits.

Hot Products

SiC Coated Barrel Susceptor for LPE Epitaxial Growth

Semicorex SiC Coated Barrel Susceptor for LPE Epitaxial Growth is a high-performance product designed to provide consistent and reliable performance over an extended period. Its even thermal profile, laminar gas flow pattern, and prevention of contamination make it an ideal choice for the growth of high-quality epitaxial layers on wafer chips. Its customizability and cost-effectiveness make it a highly competitive product in the market.SiC Graphite RTP Carrier Plate for MOCVD

Semicorex SiC Graphite RTP Carrier Plate for MOCVD offers superior heat resistance and thermal uniformity, making it the perfect solution for semiconductor wafer processing applications. With a high-quality SiC coated graphite, this product is engineered to withstand the harshest deposition environment for epitaxial growth. The high thermal conductivity and excellent heat distribution properties ensure reliable performance for RTA, RTP, or harsh chemical cleaning.SiC Susceptor for MOCVD

Semicorex is a leading manufacturer and supplier of SiC Susceptor for MOCVD. Our product is specially designed to cater to the needs of the semiconductor industry in growing the epitaxial layer on the wafer chip. The product is used as the center plate in MOCVD, with a gear or ring-shaped design. It has high heat and corrosion resistance, making it ideal for use in extreme environments.TaC Coated Graphite Parts

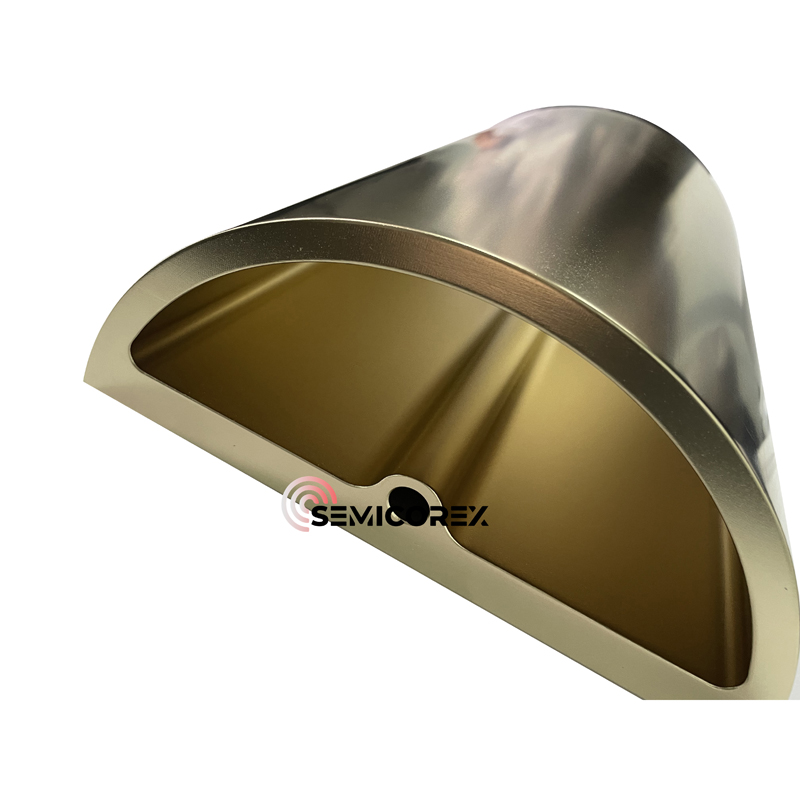

Semicorex TaC Coated Graphite Parts are precision-crafted components that are specially designed to withstand the demanding environment of semiconductor processing. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Tantalum Carbide Coating Halfmoon Part

Semicorex Tantalum Carbide Coating Halfmoon Part is a highly specialized component designed for use in the epitaxial deposition process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Coating Heater

The CVD SiC coating of Semicorex SiC Coating Heater offers superior performance in protecting heating elements from the harsh, corrosive, and reactive environments often encountered in processes such as Metal-Organic Chemical Vapor Deposition (MOCVD) and Epitaxial Growth.**