- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

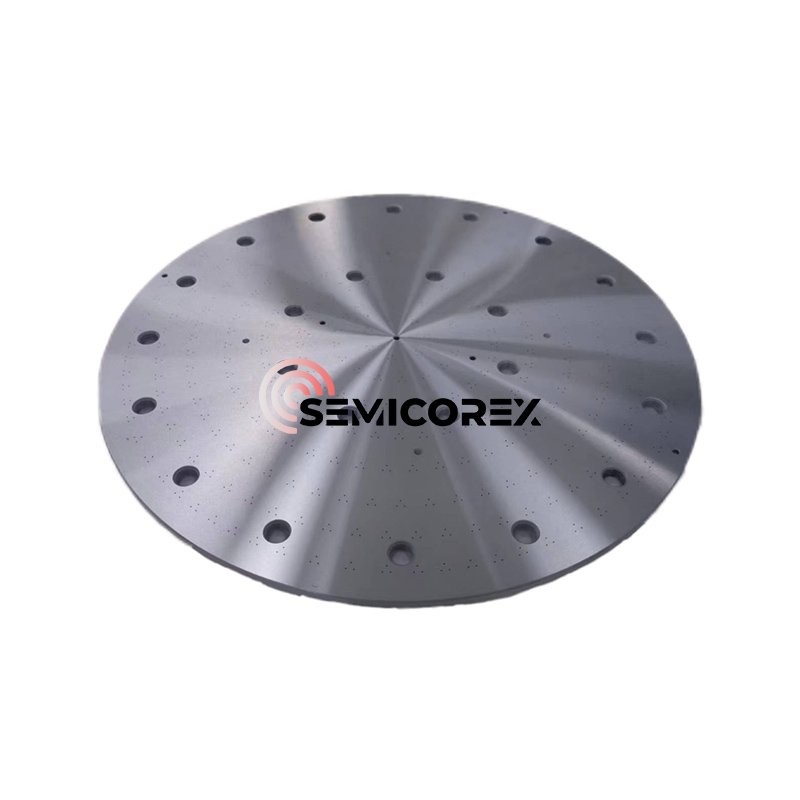

Surface Treatment For High-end Electrostatic Chuck

The electrostatic Chuck undertakes multiple functions such as uniform electrostatic discharge, heat conduction and wafer adsorption and fixation in the field of semiconductor manufacturing. One of the core functions of the ESC is to stably adsorb wafers under extreme operating conditions such as hig......

Read MoreWhat is Doping Process?

In the manufacture of ultra-high purity wafers, wafers must reach a purity standard of over 99.999999999% to ensure the fundamental properties of semiconductors. Paradoxically, to achieve the functional construction of integrated circuits, specific impurities must be introduced locally onto the surf......

Read MoreCeramic Vacuum Chuck

Ceramic vacuum chucks are made of porous ceramic materials with uniform pore size distribution and internal interconnection. After grinding, the surface is smooth and delicate with good flatness. They are widely used in the manufacturing of semiconductor wafers such as silicon, sapphire, and galli......

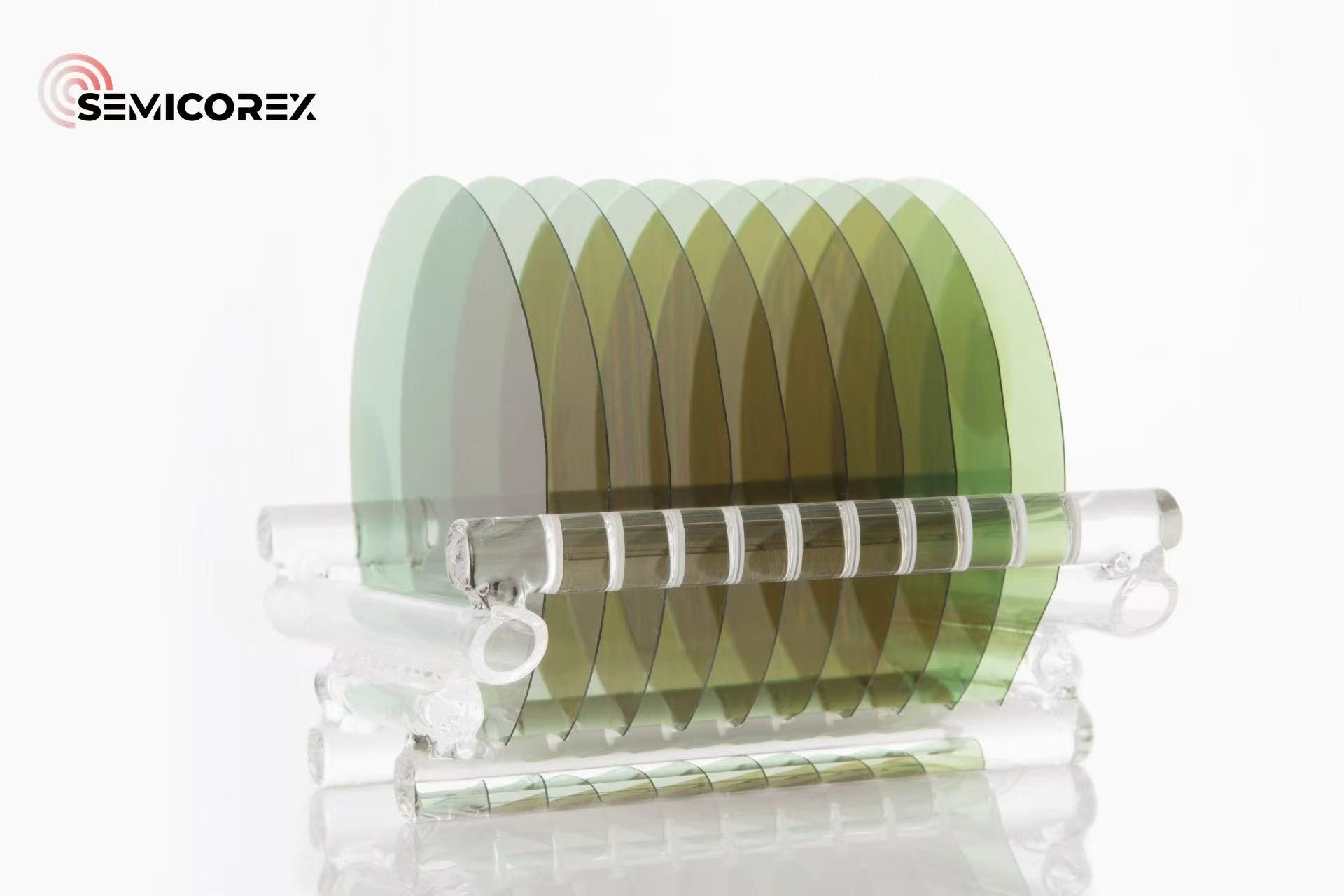

Read MoreWhat indicators Should Be Paid Attention To When Selecting Suitable Wafers?

Wafer selection has a significant impact on the development and manufacturing of semiconductor devices. Wafer selection should be guided by the requirements of specific application scenarios, and should be carefully evaluated using the following crucial metrics.

Read MoreSilicon Components for Dry Etching

Dry etching equipment uses no wet chemicals for etching. It primarily introduces a gaseous etchant into the chamber through an upper electrode with tiny through-holes. The electric field generated by the upper and lower electrodes ionizes the gaseous etchant, which then reacts with the material to b......

Read More