- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why is CO2 introduced During the Wafer Saw Process

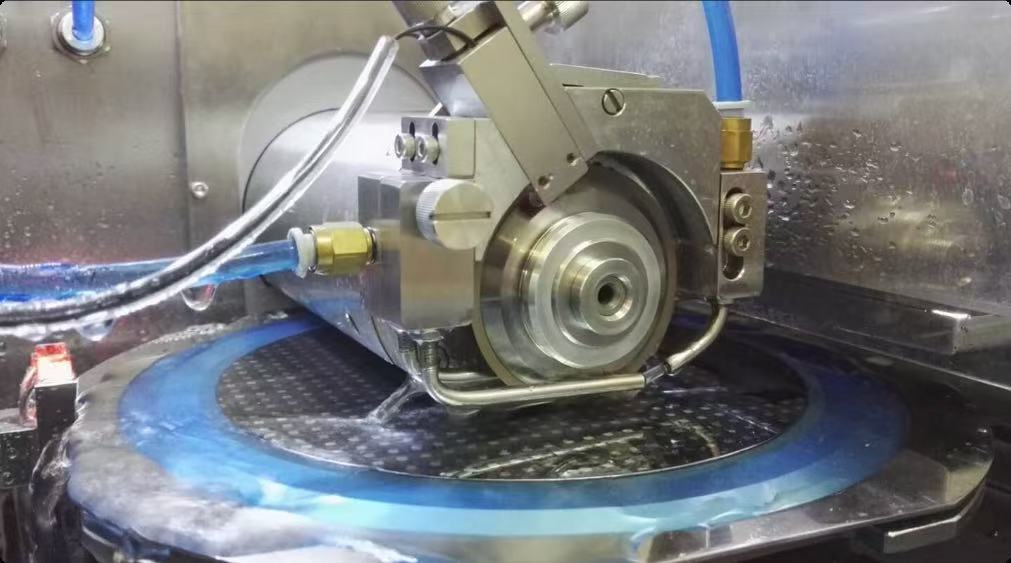

Introducing CO₂ to the dicing water is a significant technical measure in wafer saw process to suppress static electricity accumulation and reduce contamination, thereby improving the dicing yield and reliability of the chips.

Eliminate static electricity

The wafer dicing process requires the use of high-speed rotating diamond blades for cutting, while DI water is sprayed for cooling and cleaning. During this process, friction generates a large amount of static charge. Simultaneously, DI water undergoes weak ionization during high-pressure spraying and collision, generating a small number of ions. Silicon material itself has the characteristic of easily accumulating electric charge. If this static electricity is not controlled, its voltage may rise to over 500V, leading to electrostatic discharge. This can not only damage circuit metal wiring or cause interlayer dielectric cracking, but also cause silicon dust to contaminate the wafer due to electrostatic adsorption or cause bond lift problems at bonding pads.

When CO₂ is introduced into water, it dissolves and forms H₂CO₃. H₂CO₃ undergoes ionization to produce H⁺ and HCO₃⁻, which significantly increases water conductivity while effectively lowing its resistivity. This elevated conductivity allows rapid conduction of static charges to ground via the water flow, preventing charge accumulation. Furthermore, as a weakly electronegative gas, CO₂ can be ionized in high-energy environments to generate charged particles (such as CO₂⁺ and O⁻). These particles can neutralize the charge carried by wafer surfaces or dust, thereby reducing the risk of electrostatic adsorption and electrostatic discharge.

Reduce contamination and protect surfaces

Silicon dust generated during the wafer saw process is liable to accumulate static electricity, which can adhere to the wafer or equipment surface and result in contamination. At the same time, if the cooling water is alkaline, it will cause metal particles ( such as Fe, Ni, and Cr ions in stainless steel) to form hydroxide precipitates. Hydroxide precipitates will be deposited on the wafer surface or in the dicing channels, affecting chip quality.

When CO₂ is introduced, it neutralizes electrical charges, weakening the electrostatic force between dust and surfaces. Meanwhile, the CO₂ airflow prevent secondary adhesion by dispersing dust in the cutting area. The addition of CO₂ also creates a mildly acidic environment that inhibits metal ion precipitation, keeping them dissolved and enabling the water flow to carry them away. Moreover, beacuse CO₂ is an inert gas, it lessens the contact between silicon dust and oxygen, preventing dust oxidation and agglomeration and further enhancing the cutting environment' cleanliness.

Semicorex offers high quality wafers for our valued customers. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com