- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are dishing and erosion in the CMP process?

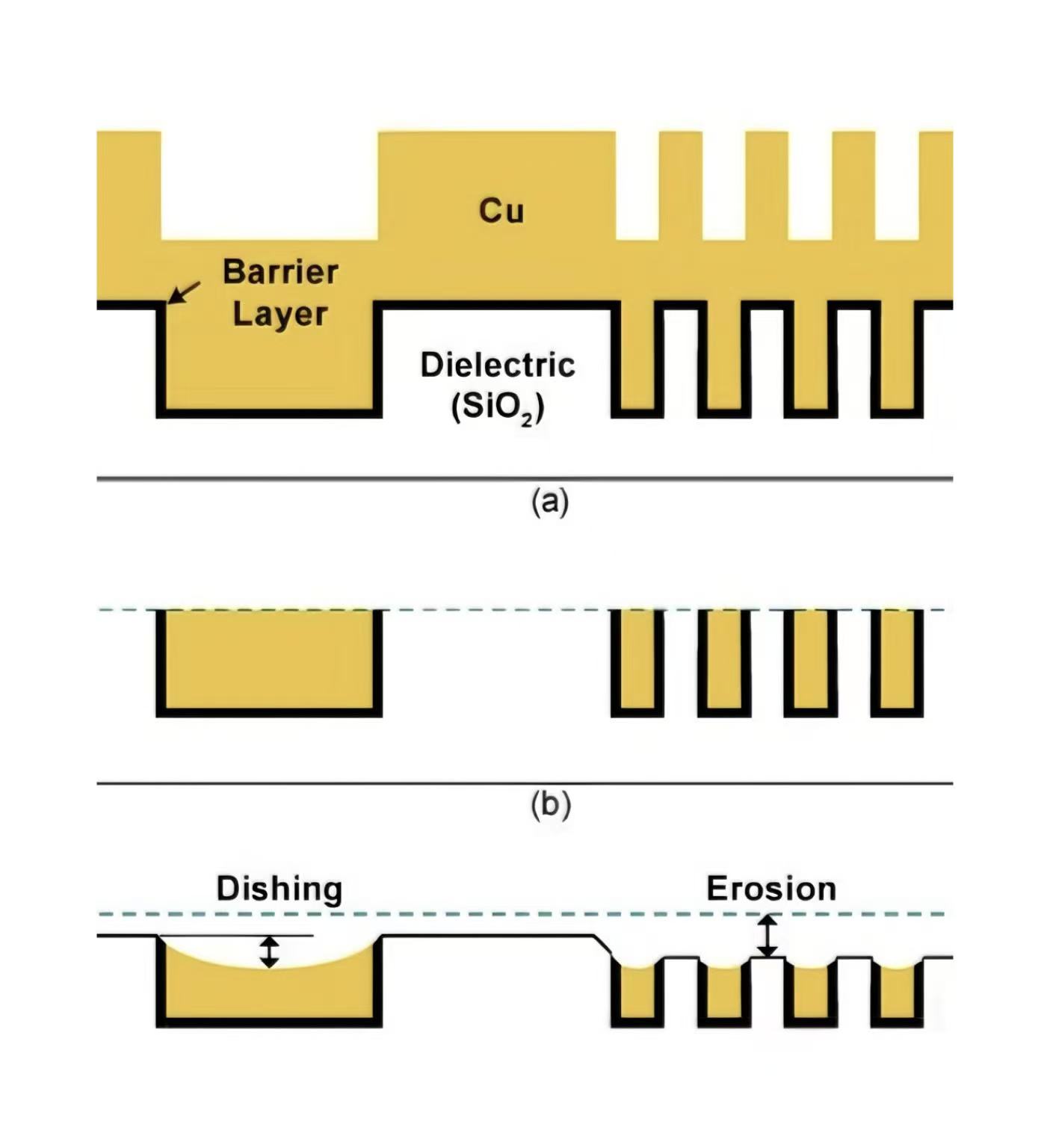

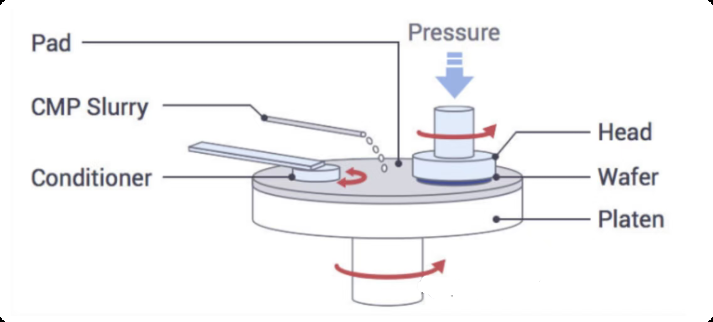

Chemical mechanical polishing (CMP), which combines chemical corrosion and mechanical polishing to remove surface imperfections, is the significant semiconductor process for achieving overall planarization of the wafer surface. CMP results in two surface defects, dishing and erosion, which significantly impact the flatness and electrical performance of interconnect structures.

Dishing means the over-polishing of softer materials (like copper) during the CMP process, resulting in localized disc-shaped central depressions. Common in wide metal lines or large metal areas, this phenomenon stems primarily from material hardness inconsistencies and uneven mechanical pressure distribution. Dishing is primarily characterized by a depression in the center of a single, wide metallic line, with the depth of the depression typically increasing with the line width.

Erosion occurs in dense patterned areas (such as high-density metal wire arrays). Due to differences in mechanical friction and material removal rates, such areas exhibit lower overall height compared to surrounding sparse areas. Erosion manifests as reduced overall height of dense patterns, with erosion severity intensifying as the pattern density increases.

The performance of Semiconductor devices is negatively impacted by both defects in several way. They may lead to an increase in interconnection resistance, resulting in signal delay and a decline in circuit performance. In addition, dishing and erosion are also able to cause uneven interlayer dielectric thickness, disrupt the consistency of the device's electrical performance and altering the breakdown characteristics of the intermetallic dielectric layer. In subsequent processes, they may also lead yo lithography alignment challenges, poor thin-film coverage, and even metal residues, further impacting yield.

To effectively suppress those defects, CMP process performance and chip yield can be enhanced through the integration of design optimization, consumable selection, and process parameter control. Dummy metal patterns can be introduced to improve the uniformity of metal density distribution during the wiring design phase. The choice of polishing pad are able to lower defects. For example, the stiffer pad has less deformation and can help reduce dishing. What’s more, the formulation and parameter of the slurry are also critical for suppressing defects. A high selectivity ratio slurry can improve erosion, but it will increase dishing. Reducing the selection ratio has the opposite effect.

Semicorex provides wafer grinding plates for semiconductor equipment. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com