- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why have vertical furnaces become the mainstream choice?

2025-12-14

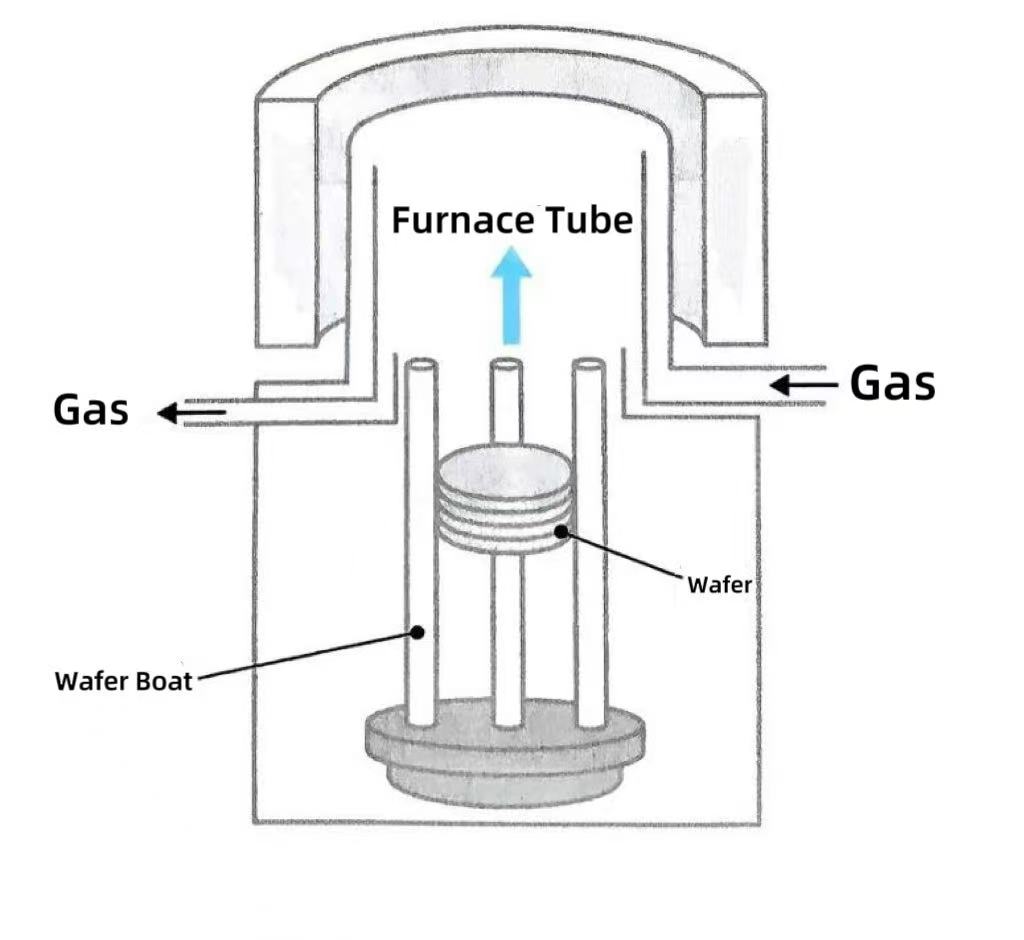

Vertical furnaces are the vertically placed high-temperature heating devices specially designed for the heat treatment of semiconductor manufacturing. The complete vertical furnace system is composed of the high-temperature resistant furnace tube, the heating element, the temperature control system, the gas control system and the wafer support structure. Vertical furnaces can facilitate critical semiconductor processes including silicon oxidation, diffusion, annealing, and atomic layer deposition (ALD) through the introduction of specialty gases (such as oxygen, hydrogen, nitrogen, etc.) under high temperature conditions.

In the evolution of heat treatment equipment in semiconductor manufacturing, vertical furnaces have become the mainstream choice for heat treatment processes due to their three core advantages.

1. From the perspective of space utilization, vertical furnaces adopt the combination design of vertical tubes and vertical wafer boats. Under the same processing capacity, their floor space requirement is only 50%-60% that of horizontal furnaces, especially suitable for enhancing the production capacity density per unit area of cleanrooms under the trend of 450mm wafer expansion. Through modular vertical stacking, the number of wafers that a single device can handle has increased by 40%, and the output efficiency per unit area is significantly better than that of the horizontal furnace.

2. Vertical furnaces achieve horizontal wafer positions through three-point groove supports. Combined with vertical airflow, this configuration delivers more uniform temperature gradients and symmetric thermal stress distribution within the furnace, cutting wafer warpage risk by more than 30%. It is particularly suitable for thermal sensitive processes, such as high-K dielectric deposition and ion implantation annealing. Conversely, the vertical placement of horizontal furnaces is prone to cause temperature variations at the wafer edges and increase the risk of local stress concentration.

3. The convenience of automated wafer handling is another critical advantage of vertical furnaces. Horizontal furnaces require robotic arms to pick up wafers in a vertical orientation, which demands stringent requirements on positioning accuracy and clamping force control. They increase the risk of wafer breakage due to operational discrepancies. In the vertical furnace, the wafers are placed horizontally. The robotic arm can achieve contact-free handling through vacuum adsorption. Combined with the visual positioning system, the handling accuracy is improved to ±0.1mm, greatly enhancing the overall level of automation.