- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

High-purity Fused Quartz Crucible for Single-crystal Pulling

2025-12-10

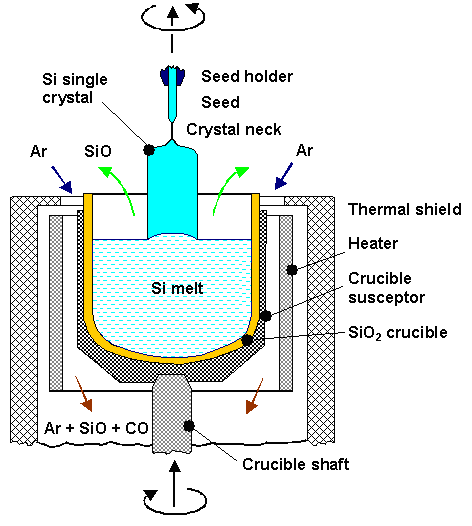

Currently, monocrystalline silicon is produced using polycrystalline silicon as a raw material and the Czochralski method. In monocrystalline silicon production, the quartz crucible is a critical material for melting silicon and crystal growth, and it has a direct and significant impact on the production cost and product quality of monocrystalline silicon.

The quartz crucible is a key component of the Czochralski single-crystal furnace. The single-crystal preparation stage determines technical parameters such as the diameter, crystal orientation, doping conductivity type, resistivity range and distribution, oxygen and carbon concentration, minority carrier lifetime, and lattice defects of the silicon material. Micro-defects, oxygen concentration, metal impurities, and carrier concentration uniformity all need to be controlled within a certain range. In the Czochralski single-crystal process, the quartz crucible needs to withstand high temperatures above the melting point of silicon (1420°C). Quartz crucibles are mostly semi-transparent and composed of multiple layers. The outer layer is a region with high bubble density, called the bubble composite layer; the inner layer is a 3-5mm transparent layer, called the bubble-depleted layer. The presence of the bubble-depleted layer reduces the density of the crucible in the area in contact with the solution, thus improving single-crystal growth.

From a quality perspective, the inner layer of the quartz crucible, due to direct contact with the molten silicon, continuously dissolves into the molten silicon during the crystal pulling process. The micro bubbles in the transparent layer of the crucible continuously grow and rupture, releasing quartz particles and micro bubbles into the molten silicon. These impurities, in the form of micro particles and micro bubbles, are carried throughout the entire silicon melt by the silicon liquid flow, directly affecting the crystallization of silicon and the quality of the single crystal.

From a cost perspective, quartz crucibles have a strong consumable characteristic in the monocrystalline silicon industry chain, and the use of continuous Czochralski method also places higher demands on the lifespan of the quartz crucible. The high purity and high temperature resistance of the quartz crucible provide a guarantee for single-crystal pulling and single-crystal quality. Based on the purity requirements of monocrystalline silicon wafers, the quartz crucible is discarded after one or several heating and crystal pulling cycles and needs to be replaced regularly, making it a consumable item.

In addition, if the quartz crucible has quality problems during the crystal pulling process, it will cause the entire single-crystal silicon rod to be scrapped. Quartz crucibles are primarily produced using the electric arc method, with high-purity quartz sand as the core raw material. The purity of the quartz sand is a crucial factor affecting the quality of the quartz crucible. The quartz crucible has a two-layer structure: the outer layer is a high-density region, called the bubble composite layer; the inner layer is a 3-5mm transparent layer, called the bubble-depleted layer.

The presence of the inner layer, the bubble-depleted layer, reduces the bubble density in the area where the crucible contacts the solution. The lower the purity of the quartz sand, the more likely it is to produce black spots and bubbles during the high-temperature melting process. When used as the inner layer sand, prolonged exposure to high temperatures causes the bubbles contained in the inner wall of the quartz crucible to be released, thus affecting the stability and success rate of single-crystal silicon wafer production. Therefore, the inner layer sand requires higher purity quartz sand, resulting in a higher price. Furthermore, the quartz sand used for crucibles has specific requirements for different impurity levels. For example, excessive alkali metal impurities can cause crystallization in the crucible, leading to opacification and deformation, while excessive hydroxyl content can cause blistering of the crucible.

Semicorex offers high-purity fused quartz crucible for Silicon single-crystal pulling. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com