- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

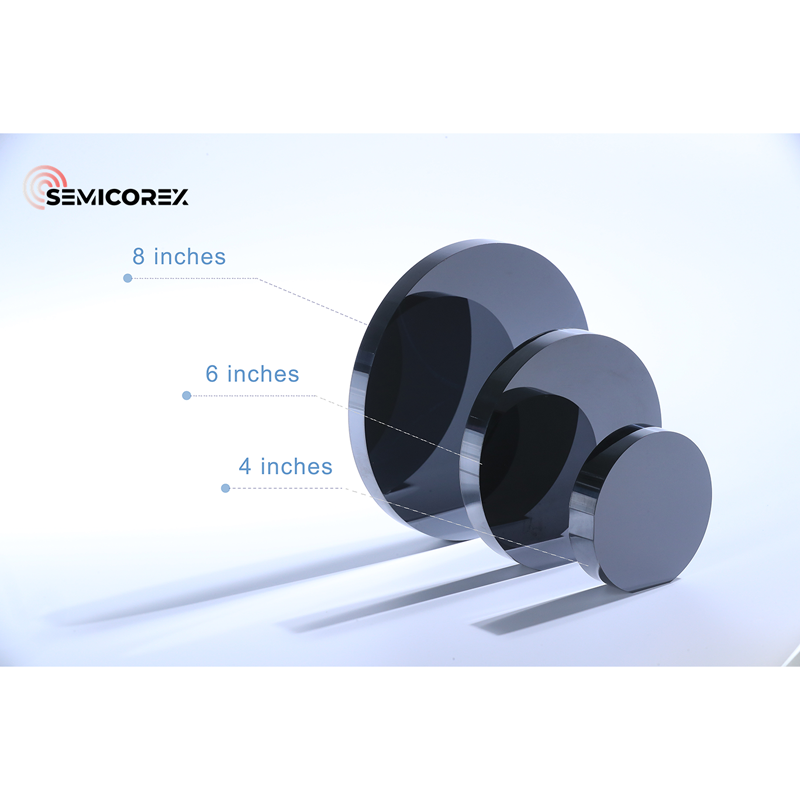

4 Inch High Purity Semi-Insulating HPSI SiC Double-side Polished Wafer Substrate

Semicorex provides various types of 4H and 6H SiC wafers. We have been manufacturer and supplier of wafer substrates for many years. Our 4 Inch High Purity Semi-Insulating HPSI SiC Double-side Polished Wafer Substrate has a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.

Send Inquiry

Semicorex has a complete silicon carbide(SiC) wafer products line, including 4H and 6H substrates with N-type, P-type and high purity semi-insulating wafers, they can be with or without epitaxy.

Introducing our cutting-edge 4 Inch High Purity Semi-Insulating HPSI SiC Double-side Polished Wafer Substrate, a top-of-the-line product that is designed to meet the demanding requirements of advanced electronic and semiconductor applications.

4 Inch High Purity Semi-Insulating HPSI SiC Double-side Polished Wafer Substrate is mainly used in 5G communications, radar systems, guidance heads, satellite communications, warplanes and other fields, with the advantages of enhancing the RF range, ultra-long-range identification, anti-jamming and high-speed, high-capacity information transfer and other applications, is considered the most ideal substrate for making microwave power devices.

Specifications:

● Diameter: 4″

● Double-polished

●l Grade: Production, Research, Dummy

● 4H-SiC HPSI Wafer

● Thickness: 500±25 μm

●l Micropipe Density: ≤1 ea/cm2 ~ ≤10 ea/cm2

|

Items |

Production |

Research |

Dummy |

|

Crystal Parameters |

|||

|

Polytype |

4H |

||

|

Surface orientation on-axis |

<0001 > |

||

|

Surface orientation off-axis |

0±0.2° |

||

|

(0004)FWHM |

≤45arcsec |

≤60arcsec |

≤1OOarcsec |

|

Electrical Parameters |

|||

|

Type |

HPSI |

||

|

Resistivity |

≥1 E9ohm·cm |

100% area > 1 E5ohm·cm |

70% area > 1 E5ohm·cm |

|

Mechanical Parameters |

|||

|

Diameter |

99.5 - 100mm |

||

|

Thickness |

500±25 μm |

||

|

Primary flat orientation |

[1-100]±5° |

||

|

Primary flat length |

32.5±1.5mm |

||

|

Secondary flat position |

90° CW from primary flat ±5°. silicon face up |

||

|

Secondary flat length |

18±1.5mm |

||

|

TTV |

≤5 μm |

≤10 μm |

≤20 μm |

|

LTV |

≤2 μm(5mm*5mm) |

≤5 μm(5mm*5mm) |

NA |

|

Bow |

-15μm ~ 15μm |

-35μm ~ 35μm |

-45μm ~ 45μm |

|

Warp |

≤20 μm |

≤45 μm |

≤50 μm |

|

Front(Si-face) roughness(AFM) |

Ra≤0.2nm (5μm*5μm) |

||

|

Structure |

|||

|

Micropipe density |

≤1 ea/cm2 |

≤5 ea/cm2 |

≤10 ea/cm2 |

|

Carbon inclusion density |

≤1 ea/cm2 |

NA |

|

|

Hexagonal void |

None |

NA |

|

|

Metal impurities |

≤5E12atoms/cm2 |

NA |

|

|

Front Quality |

|||

|

Front |

Si |

||

|

Surface finish |

Si-face CMP |

||

|

Particles |

≤60ea/wafer (size≥0.3μm) |

NA |

|

|

Scratches |

≤2ea/mm. Cumulative length ≤Diameter |

Cumulative length≤2*Diameter |

NA |

|

Orange peel/pits/stains/striations/ cracks/contamination |

None |

NA |

|

|

Edge chips/indents/fracture/hex plates |

None |

||

|

Polytype areas |

None |

Cumulative area≤20% |

Cumulative area≤30% |

|

Front laser marking |

None |

||

|

Back Quality |

|||

|

Back finish |

C-face CMP |

||

|

Scratches |

≤5ea/mm,Cumulative length≤2*Diameter |

NA |

|

|

Back defects (edge chips/indents) |

None |

||

|

Back roughness |

Ra≤0.2nm (5μm*5μm) |

||

|

Back laser marking |

1 mm (from top edge) |

||

|

Edge |

|||

|

Edge |

Chamfer |

||

|

Packaging |

|||

|

Packaging |

The inner bag is filled with nitrogen and the outer bag is vacuumed. Multi-wafer cassette, epi-ready. |

||

|

*Notes: "NA" means no request Items not mentioned may refer to SEMI-STD. |

|||

![]()

![]()