- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

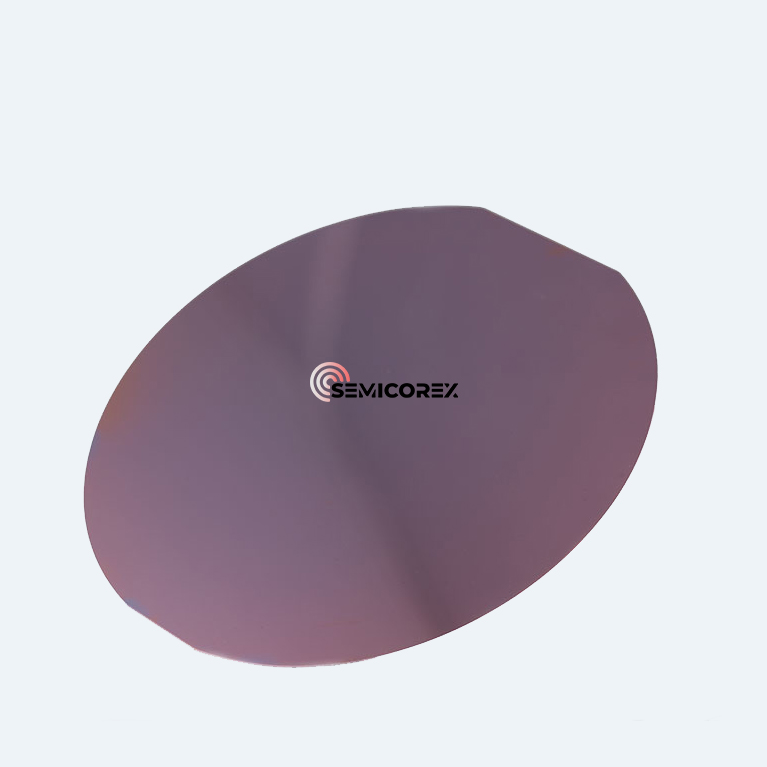

Si Dummy Wafer

Semicorex Si Dummy Wafer, crafted from either monocrystalline or polycrystalline silicon, shares the same foundational material as production wafers. Its similar thermal and mechanical properties are ideal for simulating real production conditions without the associated costs.

Send Inquiry

Features of the Semicorex Si Dummy Wafer Material

Structure and Composition

Silicon that is either monocrystalline or polycrystalline is commonly used to create Semicorex Si Dummy Wafer. The particular needs of the process that silicon is meant to assist frequently determine whether monocrystalline or polycrystalline silicon is best. While polycrystalline silicon is more affordable and adequate for a wide range of applications, monocrystalline silicon provides better homogeneity and fewer flaws.

Reusability and Durability

One of Si Dummy Wafer's distinguishing characteristics is its multi-use capability, which offers a major financial benefit. However, the environmental factors they are exposed to during processing have a significant impact on how long they live. Their usable life may be shortened by high temperatures and corrosive conditions, therefore careful monitoring and prompt replacement are necessary to preserve process integrity. Notwithstanding these difficulties, Si Dummy Wafers continue to be substantially less expensive overall than production wafers, offering a strong return on investment.

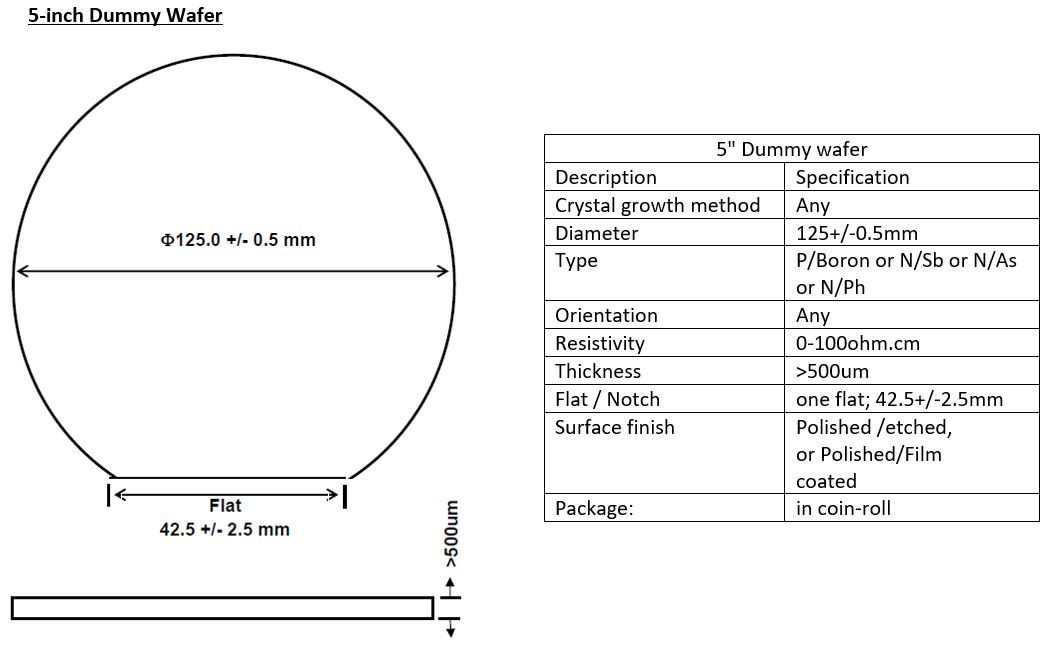

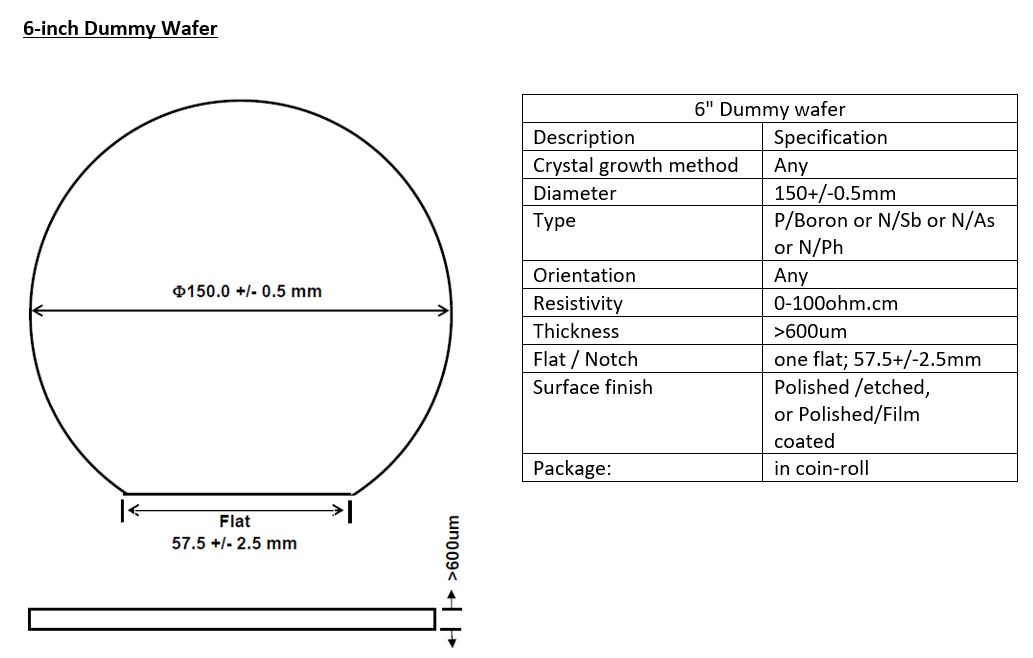

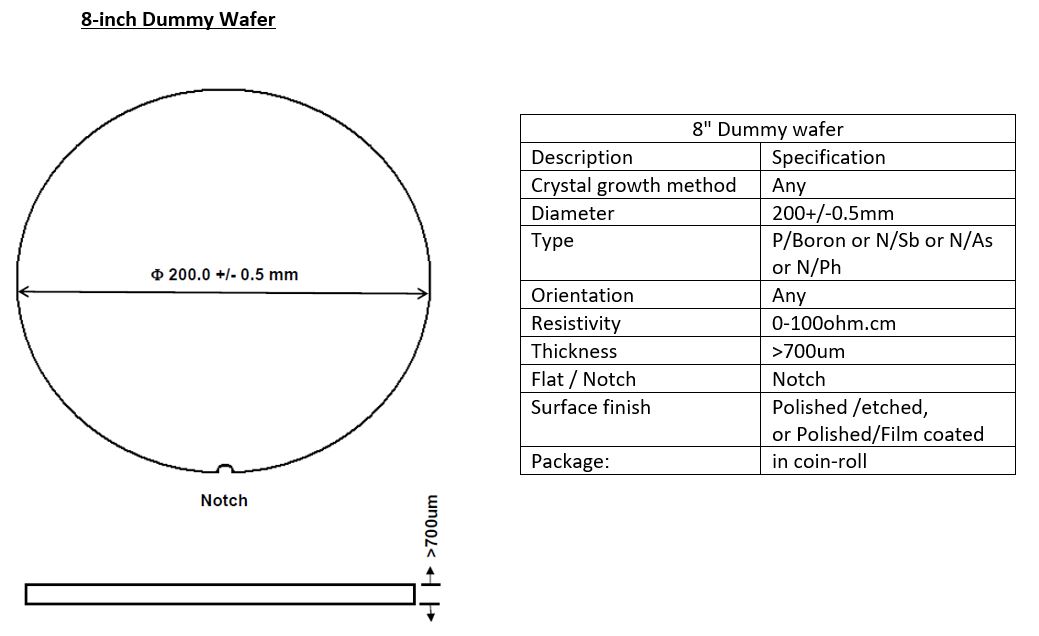

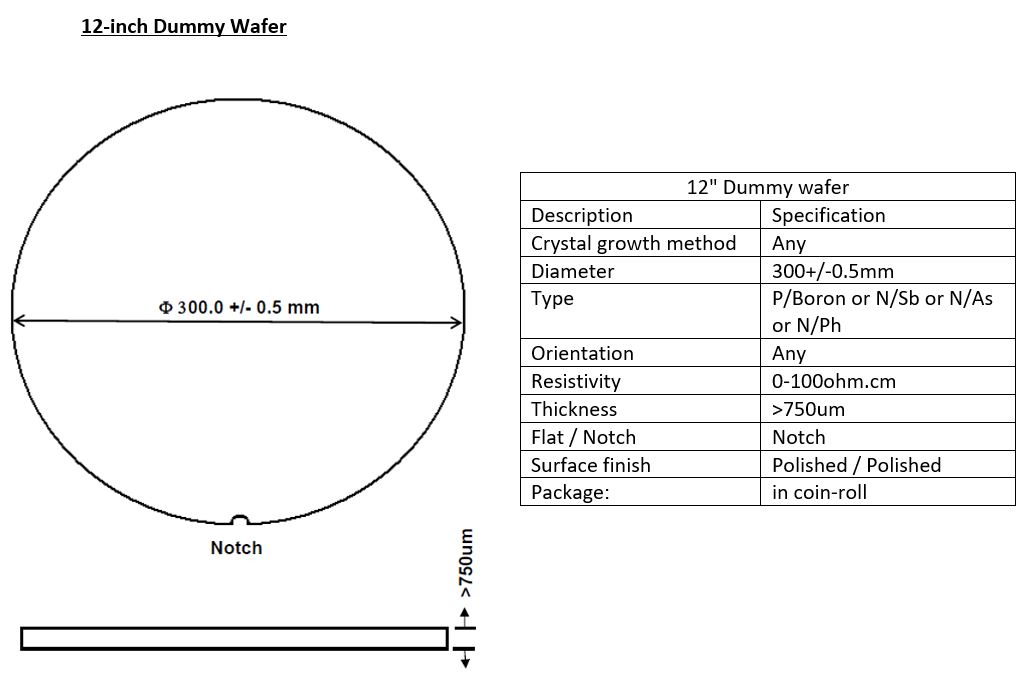

Availability of Size

Five-, six-, eight-, and twelve-inch diameters are among the sizes of Si Dummy Wafer that are available to meet the various requirements of semiconductor production equipment. Because of their adaptability, they may be utilised in a variety of equipment kinds and procedures, guaranteeing that they can satisfy the unique requirements of each given industrial setup.

Utilising Si Dummy Wafers

Equipment Load Distribution

Certain pieces of machinery, such furnace tubes and etching machines, need a certain quantity of wafers in order to operate at their best during the semiconductor production process. In order to satisfy these specifications and guarantee that the machinery runs effectively, Si Dummy Wafer is an essential filler. They contribute to process environment stabilisation by keeping the required wafer count, which produces consistent and dependable production results.

Mitigation of Process Risk

Si Dummy Wafer provides protection during high-risk procedures like as chemical vapour deposition (CVD), etching, and ion implantation. To detect and reduce any hazards such process instability or particle contamination, they are added to the process flow before production wafers. By avoiding exposure to unfavourable conditions, this proactive approach helps protect the production wafer yield.

Physical Vapour Deposition (PVD) Uniformity

Uniform wafer distribution within the apparatus is essential for attaining constant deposition rates and film thicknesses in procedures like as physical vapour deposition (PVD). By guaranteeing that wafers are dispersed uniformly, Si Dummy Wafer preserves the stability and consistency of the entire procedure. The production of superior semiconductor devices depends on this homogeneity.

Use and Upkeep of Equipment

Si Dummy Wafer plays a crucial role in keeping machinery operating when output demand is low. They save time and money by keeping machinery running and avoiding the inefficiencies that come with frequent starts and stops. They also serve as test substrates for equipment replacement, cleaning, and maintenance, enabling equipment performance to be confirmed without endangering priceless production wafers.

Efficient Control and Enhancement of Si Dummy Wafer Utilisation

Monitoring and Improving Usage

Monitoring Si Dummy Wafer consumption, process flows, and wear conditions is crucial to maximising its efficiency. Manufacturers can optimise their usage cycles, improving resource utilisation and cutting waste, thanks to this data-driven strategy.

Control of Contamination

Si Dummy Wafers must be cleaned or replaced on a regular basis to ensure a clean processing environment because frequent use might cause particle contamination. The quality of ensuing production runs is maintained by keeping equipment free of impurities through the implementation of a strict cleaning program.

Selection Based on Process

Si Dummy Wafer is subject to specific criteria from various semiconductor processes. For example, the wafer's surface smoothness can have a big influence on the quality of the film produced during thin-film deposition procedures. For this reason, choosing the right Si Dummy Wafer based on process parameters is essential to getting the best outcomes.

Management of Inventory and Disposal

Effective inventory management is required to match production needs with cost control, even when Si Dummy Wafer is not included in the finished product. They should be disposed of in compliance with environmental rules when their lifecycle is over. To reduce environmental impact and maximise resource efficiency, options include recycling the silicon material or using the wafers for lower-grade testing purposes.