- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

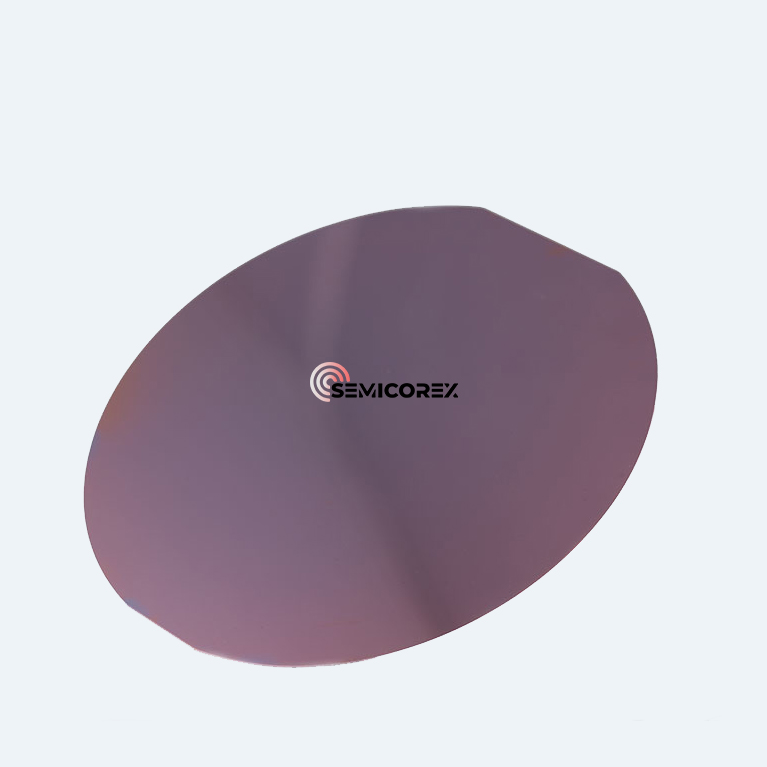

Monocrystalline Silicon Wafers

Monocrystalline silicon wafers, crafted by the excellent high-purity monocrystalline silicon, offer exceptional flatness, low defect density, and superior quality. Semicorex prioritizes customer needs and is committed to providing premium wafer solutions required for advanced semiconductor industry.

Send Inquiry

In the production of monocrystalline silicon wafers, the Czochralski (CZ) method is used to produce monocrystalline silicon rods with complete structure and extremely low impurity

content. Then, these monocrystalline silicon rods undergo precise processing such as cutting, grinding, polishing and cleaning to be made into monocrystalline silicon wafers. These monocrystalline silicon wafers have a high purity, especially the wafer at the IC level, which can reach over 9N (99.9999999%), efficient ensuring excellent electrical performance.

Monocrystalline silicon occupies more than 90% of the semiconductor material market. It is currently the most significant semiconductor material, widely used in information technology and integrated circuit manufacturing industries.

Application areas:

1.high-performance logic chips(such as CPU、GPU、FPGA), memory chips(such as DRAM、NAND Flash), analog chips (such as ADC and DAC) in the integrated circuit manufacturing industry.

2.High-end electronic devices ( such as CMOS image sensors (CIS) and MEMS sensors) in the information technology industry.

Wafer specification:

|

Diameter |

2" | 3" | 4" | 5" | 6" | 8" | 12" |

|

Growth Method |

Czochralski (CZ) |

||||||

|

Type/Dopant |

P Type/Boron , N Type/Phos, N Type/As, N Type/Sb |

||||||

|

Thickness (μm) |

279 |

380 | 525 | 625 | 675 | 725 | 775 |

|

Thickness Tolerance |

Standard ± 25μm, Maximum Capabilities ± 5μm |

± 20μm |

± 20μm |

||||

|

TTV (μm) |

Standard < 10 μm, Maximum Capabilities <5 μm |

||||||

|

Bow/Warp (μm) |

Standard <40 μm, Maximum Capabilities <20 μm |

<40μm |

<40μm |

||||

Semicorex provides customized services for its customers and can customize wafers with different resistivity, oxygen content, thickness and other specifications according to the specific needs of different customers. To assist clients in resolving a range of issues that arise throughout the production process, we also provide expert technical support and after-sales service.