- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Silicon carbide substrate Manufacturers, Suppliers, Factory

"Based on domestic market and expand abroad business" is our improvement strategy for Silicon carbide substrate,SiC coated graphite susceptor,Graphite tray,Graphite susceptor,CVD Sic Coating, Now we have established steady and long business relationships with customers from North America, Western Europe, Africa, South America, more than 60 countries and regions.

Silicon carbide substrate, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we offer, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and comprehensive parameters and any other info weil be sent for you timely for the inquiries. So remember to get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we're likely to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Hot Products

High-Temperature SiC-Coated Barrel Susceptor

When it comes to semiconductor manufacturing, the Semicorex High-Temperature SiC-Coated Barrel Susceptor is the top choice for superior performance and reliability. Its high-quality SiC coating and exceptional thermal conductivity make it ideal for use in even the most demanding high-temperature and corrosive environments.TaC Coated Graphite Susceptor

Semicorex cutting-edge TaC Coated Graphite Susceptor, a revolutionary component designed to elevate your wafer epitaxial process to new heights of efficiency and precision. Crafted with unparalleled expertise and utilizing state-of-the-art technology, Semicorex TaC Coated Graphite Susceptor is engineered to meet the exacting demands of semiconductor manufacturing.Susceptor with Grid

Semicorex Susceptor with Grid is a specialized component used in the epitaxial growth process of semiconductor wafers. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Spare Parts in Epitaxial Growth

Semicorex Spare Parts in Epitaxial Growth are crucial components utilized within epitaxial growth systems, particularly in processes involving quartz tube setups. These parts play a vital role in facilitating gas flow to drive tray base rotation and ensure precise temperature control throughout the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Tantalum Carbide Halfmoon Part

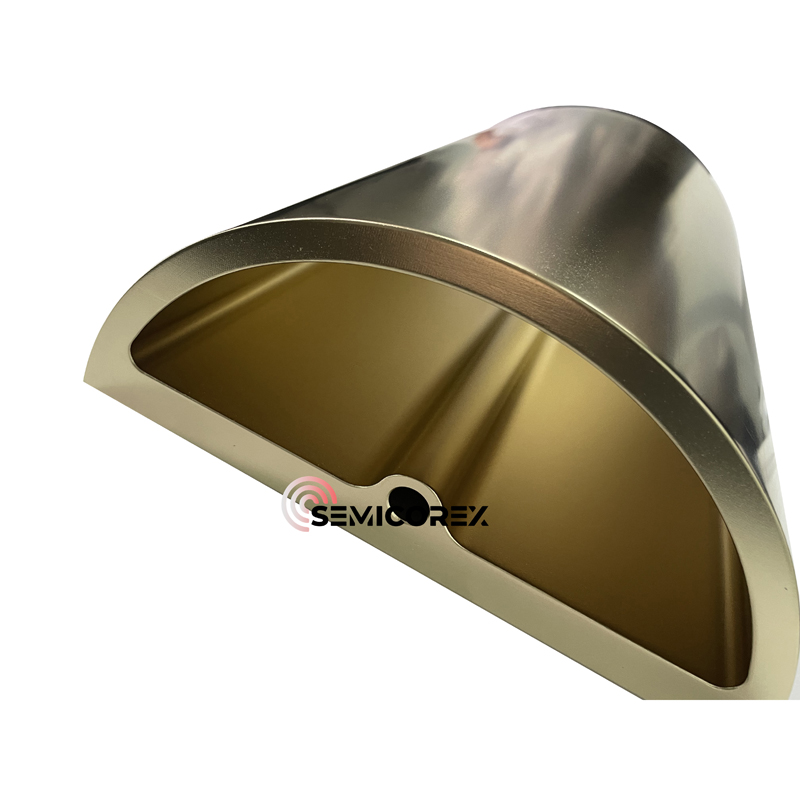

Semicorex Tantalum Carbide Halfmoon Part is a crucial component utilized in the semiconductor epitaxy process, a critical stage in the manufacturing of semiconductor devices. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China*.Upper Half Moon

Semicorex Upper Half Moon is a semi-circular SiC coated graphite wafer susceptor designed for use in epitaxial reactors. Choose Semicorex for industry-leading material purity, precision machining, and uniform SiC coating that ensures long-lasting performance and superior wafer quality.*