- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China shield ring Manufacturers, Suppliers, Factory

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for shield ring,etch ring,focus ring,etching process,etching machine, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build up long well business relationship with you.

shield ring, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. We hope to get inquiries from you and construct a long-term co-operation partnership.

Hot Products

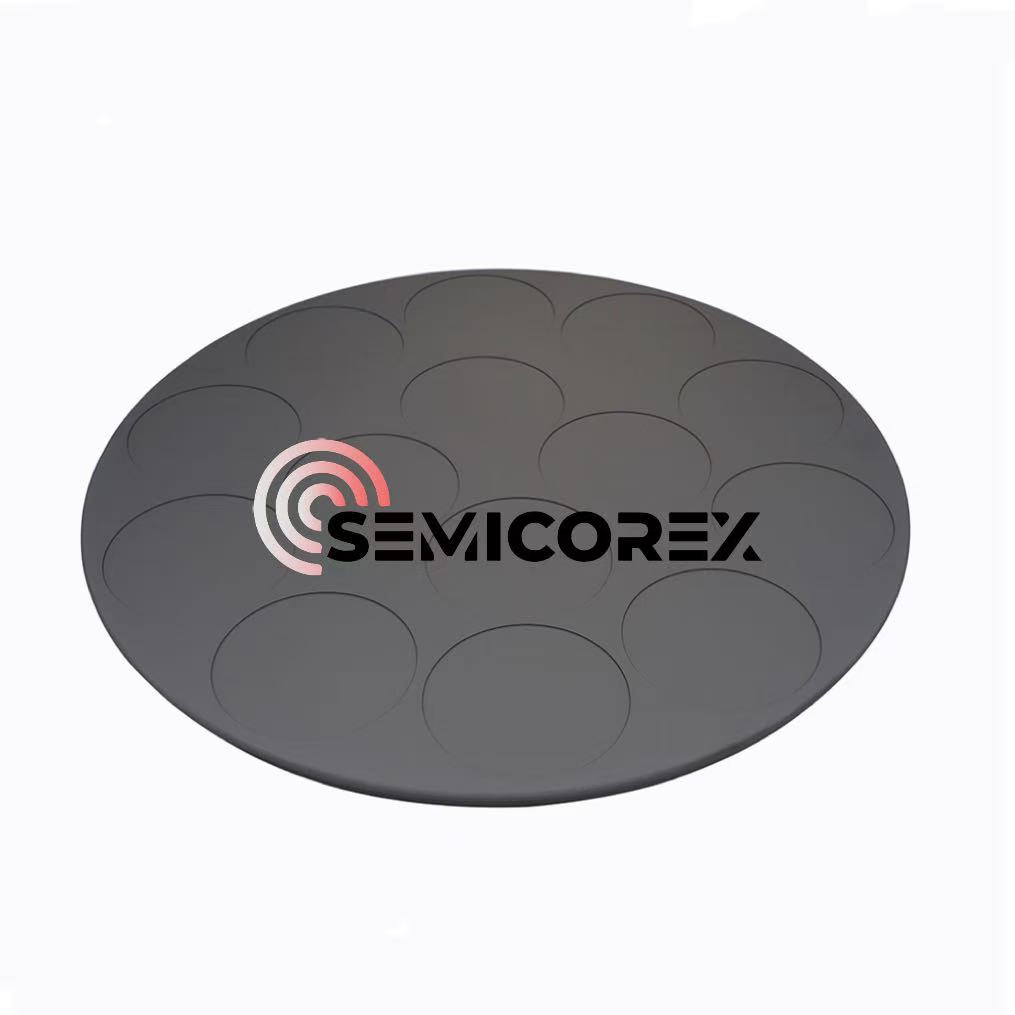

SiC Coated RTP Carrier Plate for Epitaxial Growth

Semicorex SiC Coated RTP Carrier Plate for Epitaxial Growth is the perfect solution for semiconductor wafer processing applications. With its high-quality carbon graphite susceptors and quartz crucibles processed by MOCVD on the surface of graphite, ceramics, etc., this product is ideal for wafer handling and epitaxial growth processing. The SiC coated carrier ensures high thermal conductivity and excellent heat distribution properties, making it a reliable choice for RTA, RTP, or harsh chemical cleaning.Blue Green LED Epitaxial Susceptor

Semicorex Blue Green LED Epitaxial Susceptors make the manufacture of high-quality LED wafers more efficient. We have been manufacturer and supplier of silicon carbide coated susceptor for many years. Our Blue Green LED Epitaxial Susceptor has a good price advantage and cover most of the European and American markets. We look forward to becoming your long-term partner in China.Susceptor Disc

The Semicorex Susceptor Disc is an indispensable tool in Metal-Organic Chemical Vapor Deposition (MOCVD), specifically engineered for supporting and heating semiconductor wafers during the critical process of epitaxial layer deposition. The Susceptor Disc is instrumental in the manufacturing of semiconductor devices, where precise layer growth is paramount. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.Tantalum Carbide Coating Chuck

Semicorex Tantalum Carbide Coating Chuck is a precision-engineered component designed for use in high-temperature and high-stress environments. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Epitaxial Susceptor

Semicorex Epitaxial Susceptor with SiC coating is designed to support and hold SiC wafers during the epitaxial growth process, ensuring precision and uniformity in semiconductor manufacturing. Choose Semicorex for its high-quality, durable, and customizable products that meet the rigorous demands of advanced semiconductor applications.*SiC-coated Graphite MOCVD Susceptors

SiC-coated graphite MOCVD susceptors are the essential components used in Metal-organic chemical vapor deposition (MOCVD) equipment, which are responsible for holding and heating wafer substrates. With their superior thermal management, chemical resistance, and dimensional stability, SiC-coated graphite MOCVD susceptors are regarded as the optimal option for high-quality wafer substrate epitaxy. In the wafer fabrication, the MOCVD technology is used to construct epitaxial layers on the surface of wafer substrates, preparing for the fabrication of advanced semiconductor devices. Since the growth of epitaxial layers is affected by multiple factors, the wafer substrates cannot be directly placed in the MOCVD equipment for deposition. SiC-coated graphite MOCVD susceptors are required to hold and heat the wafer substrates, creating stable thermal conditions for the growth of epitaxial layers. Therefore, the performance of SiC-coated graphite MOCVD susceptors directly determines the uniformity and purity of thin film materials, which in turn affects the manufacturing of advanced semiconductor devices.