- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China graphite heat spreader Manufacturers, Suppliers, Factory

We always think and practice corresponding to the change of circumstance, and grow up. We goal at the achievement of a richer mind and body and also the living for graphite heat spreader,graphite material,pure graphite,crystalline graphite,nano graphite, For additional facts, please make contact with us as shortly as possible!

graphite heat spreader, We have been your reliable partner in international markets with the best quality items. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

Hot Products

ICP Plasma Etching System

Semicorex's SiC Coated carrier for ICP Plasma Etching System is a reliable and cost-effective solution for high-temperature wafer handling processes such as epitaxy and MOCVD. Our carriers feature a fine SiC crystal coating that provides superior heat resistance, even thermal uniformity, and durable chemical resistance.CVD SiC Coated Graphite Susceptor

Semicorex CVD SiC Coated Graphite Susceptor, is a specialized tool used in the handling and processing of semiconductor wafers. The susceptor plays a crucial role in facilitating the growth of thin films, epitaxial layers, and other coatings on substrates with precise control over temperature and material properties. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.TaC Coating Ring

Semicorex TaC Coating Ring stands as a pivotal component in the realm of monocrystal growth within the thermal field. Crafted with precision and innovation, this specialized guide ring plays a crucial role in the intricate process of monocrystalline material production. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Single-crystal Silicon Epi Susceptor

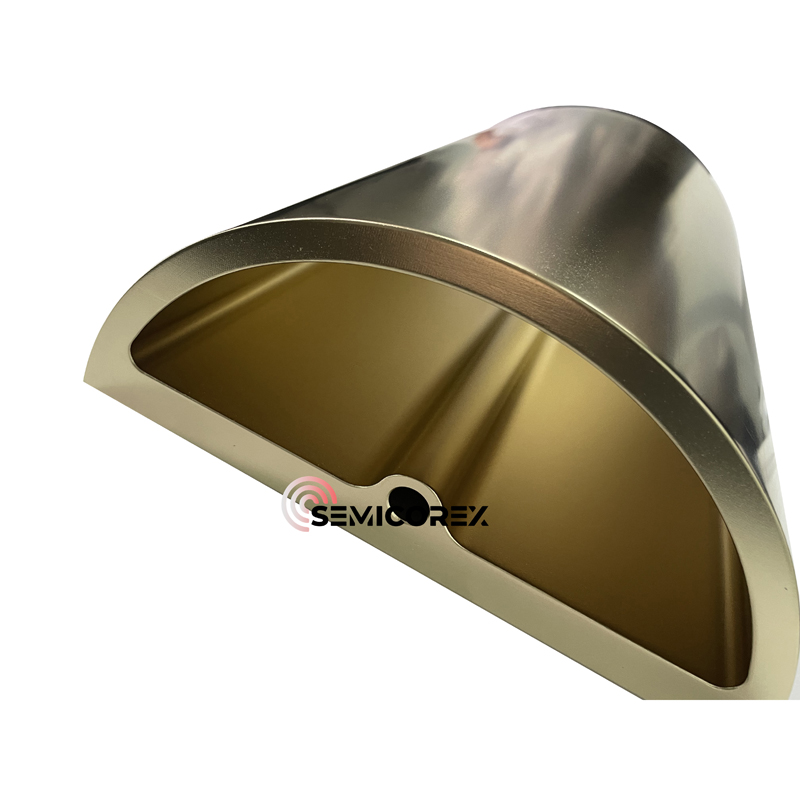

The Single-crystal Silicon Epi Susceptor is an essential component designed for Si-GaN epitaxy processes, which can be tailored to individualized specifications and preferences, providing a bespoke solution that aligns perfectly with specific requirements. Whether it entails modifications in dimensions or adjustments in coating thickness, we possess the capability to design and deliver a product that accommodates diverse process parameters, thereby optimizing performance for targeted applications. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.Tantalum Carbide Coating Halfmoon Part

Semicorex Tantalum Carbide Coating Halfmoon Part is a highly specialized component designed for use in the epitaxial deposition process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC Coated Wafer Carriers

Semicorex SiC Coated Wafer Carriers are high-purity graphite susceptors coated with CVD silicon carbide, designed for optimal wafer support during high-temperature semiconductor processes. Choose Semicorex for unmatched coating quality, precision manufacturing, and proven reliability trusted by leading semiconductor fabs worldwide.*