- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Insulation Covers

Semicorex Insulation Covers are critical thermal management component designed for optimal performance in LPE furnaces, utilizing high-strength rigid felt material to ensure consistent epitaxial growth conditions. Choose Semicorex for our proven expertise in delivering precision-engineered, high-purity furnace components that enhance process stability, yield, and equipment longevity.*

Send Inquiry

Semicorex Insulation Covers are specifically engineered for use in Liquid Phase Epitaxy (LPE) furnaces, providing superior thermal management during the epitaxial growth process. Designed as essential accessories for the LPE system, these Insulation Covers play a critical role in maintaining consistent furnace temperature profiles, minimizing heat loss, and enhancing overall process stability.

Our Insulation Covers offer excellent thermal insulation properties, mechanical strength, and dimensional stability at high operating temperatures. The rigid felt construction ensures that the covers maintain their shape and insulating performance even after prolonged exposure to intense thermal cycles, which is crucial for sustaining a clean and controlled epitaxial growth environment.

The Insulation Covers are precisely fabricated to fit within the LPE furnace chamber, positioned to protect and stabilize the thermal zone where substrate wafers are processed. By effectively reducing heat dissipation and external temperature fluctuations, they contribute to a more uniform thermal field, resulting in better crystalline quality and reproducibility of the epitaxial layers.

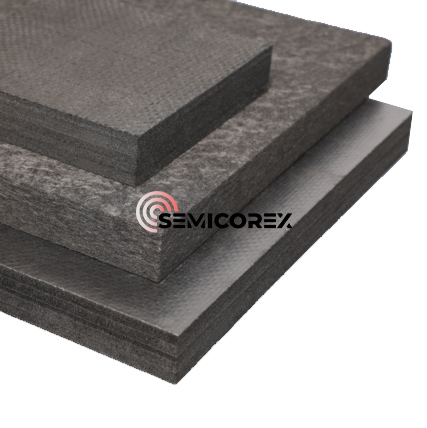

Graphite hard felt (carbon fiber-reinforced), also known as reinforced composite hard felt or cured felt (also commonly known as carbon fiber composite hard felt), is a thermal insulation material. It can be regarded as consisting of a main body (carbon fiber) and auxiliary materials (such as thermosetting resin, carbon paper, graphite paper, etc.). The general manufacturing process is to combine graphite paper, polyacrylonitrile-based carbon felt, and polyacrylonitrile-based carbon cloth into one, and then cure and form them, and then treat them at high temperature once or twice. Short carbon fiber scraps can also be used to produce carbon fiber hard felt through recycling. At the same time, according to the different types of raw materials of carbon fiber, hard felt can be divided into asphalt-based hard felt, polyacrylonitrile-based hard felt, and viscose-based hard felt.

The lamination method is to bond thin carbon fiber felts layer by layer with thermosetting resin. By placing the prepregs laid layer by layer between the upper and lower flat molds and curing them under pressure and high temperature, this process can directly use the production methods and equipment of wood plywood, and improve and perfect them according to the flow properties of the resin. This molding process is mainly used to produce composite materials of different specifications and different uses.

Needle punched integral structure refers to a method of preparing a rigid carbon fiber integral felt by connecting carbon fibers into a felt body of a certain thickness through a needle punching process, directly hot pressing and forming the thermal insulation material through dipping, and then carbonizing, graphitizing and subsequent chemical vapor deposition processes. This method not only overcomes the shortcomings of the rigid carbon fiber integral felt prepared by the traditional lamination method, such as insufficient transverse shear strength, easy dissection and cracking, and uneven overall density and performance, but also has the characteristics of simple process, low cost and short cycle compared to the three-dimensional woven structure.