- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

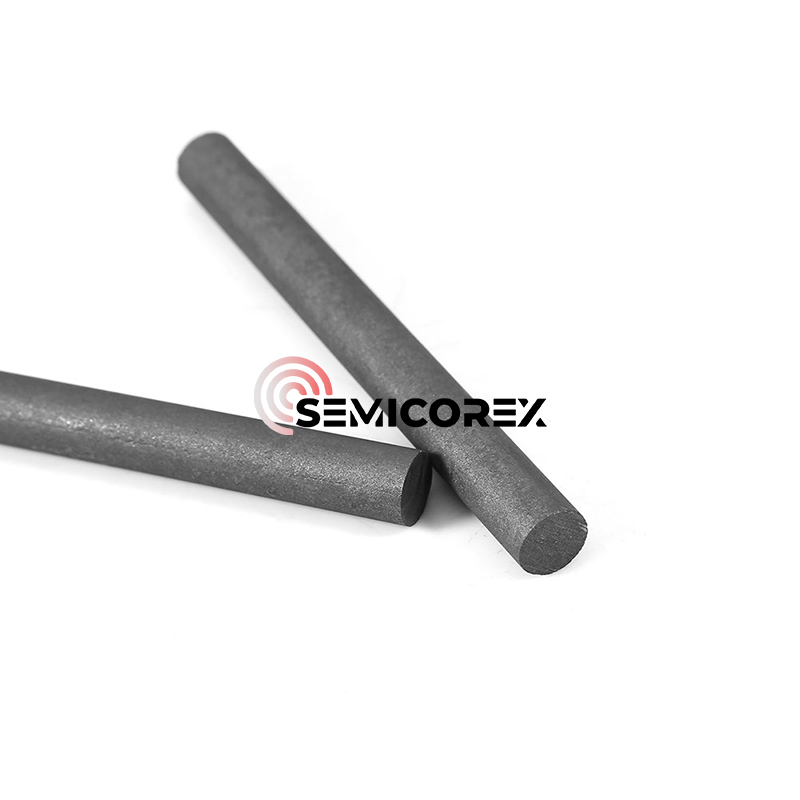

Graphite Electrode

Semicorex Graphite Electrode is a high-purity, fine-grain graphite rod engineered for precise electrical conduction and superior thermal stability in semiconductor furnace applications.Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China*.

Send Inquiry

Semicorex Graphite Electrode is a high-purity, precision manufactured graphite component for use in semiconductor thermal applications, where electrical conductivity, thermal stability and dimensional accuracy are paramount. In fact, these type of electrodes are used in high-temperature furnaces, epitaxy reactors and thermal processing chambers, facilitating stable current conduction, heat transfer and stability under aggressive conditions of temperature and atmosphere. Due to the extreme purity, uniformity of the solid structure, and high mechanical properties of Semicorex Graphite Electrodes, they can provide reliable thermal performance as heating elements in demanding semiconductor applications

The graphite eletrode is manufactured from high quality fine-grain graphite material, each one is made using an advanced sequence of extrusion, high-temperature carbonization and graphitization. The graphite microstructure is designed for approximately constant electrical resistivity, high thermal conductivity and mechanical stability. The final product is a high-purity thermal conductor that maintains a physical condition and a uniform distribution of current in high power environments as well as rapid temperature fluctuations.

Ultra Performance in our graphite

Our graphite guarantees superior performance uniformity. Firstly, during the carbonization process, our furnaces have only 115 cubic meters. Our technical team monitors the temperature field of graphite products in different areas of each furnace. At the initial low-temperature stage (0-200°C), we control the temperature within ±10°C, and at high temperatures (above 600°C), within ±1°C. We not only monitor the temperature field between different graphite particles, but also the surface and internal temperature of each individual graphite piece, controlling it within ±3°C. We monitor 8 temperature points in each carbonization furnace.

Secondly, during the graphitization process, taking a 500 kg batch as an example, we also monitor 8 temperature points. After graphitization, we randomly sample and destructively test 24 points along the X, Y, and Z axes to ensure uniformity. Most companies in the industry only test the X-axis, or at most the XY-axis, with typical manufacturers testing only 6-8 points, and better ones testing 12 points. We test 24 points.

In the semiconductor thermal field, the Graphite Electrode is a critical part of the heating assembly, directing electric current into the heating zone and allowing for controlled distribution of temperature across a specific process, such as oxidation, diffusion, LPCVD, or epitaxy. The Graphite Electrode must hold a reliable operational role at temperatures exceeding 2000°C and do so while resisting oxidation, warping or contaminating the heating site.

Semicorex Graphite Electrodes have outstanding electrical conductivity, which facilitates effective power delivery with minimal losses, and they possess excellent thermal conductivity, permitting fast uniform heat transfer in the furnace. The combination of low thermal expansion and high mechanical strength reduces deformation and cracking during thermal cycling, yielding stable behaviour over long durations of service life. Each electrode is machined to stringent dimensional tolerances and fine surface finish to ensure consistent contact and negligible electrical resistance at the contact surface.

With the specific requirements of semiconductor processes in mind, Semicorex can engineer custom electrode designs to fit any furnace configuration and power specification. Different diameters, lengths, types of connections or surface finishes can be made available. When necessary, coating materials, such as SiC or pyrolytic carbon, can be applied to support oxidation resistance and service life in high-oxygen or reactive gas environments.

The high purity of the graphite material serves to ensure incredibly low levels of metallic impurities (and gaseous impurities), often more than 99.999% carbon. Such low levels of impurities help to avoid contaminating semiconductor wafers during thermal processing. Combined with the significant depth of machining and polished surface finish, Semicorex Graphite Electrodes meet both the mechanical and chemical stability of state-of-the-art wafer fabrication technologies.

Whether used in diffusion furnaces, epitaxial reactors, or high-temperature processing equipment, the Semicorex Graphite Electrode provides unmatched performance in the most demanding thermal environments. By combining high purity, precise geometry, and advanced material processing, Semicorex delivers an electrode solution that ensures stable current conduction, consistent heating, and long-term operational reliability essential to next-generation semiconductor manufacturing.