- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

SiC Heating Filament

Semicorex SiC Heating Filament is a silicon carbide coated graphite heater designed for wafer heating in advanced semiconductor manufacturing. Choosing Semicorex means selecting a trusted partner that delivers high-purity materials, precision customization, and long-lasting performance for the most demanding thermal processes.*

Send Inquiry

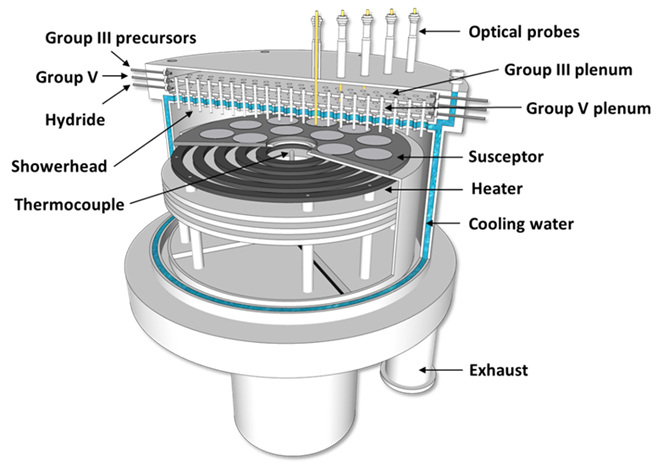

Semicorex SiC Heating Filament, a high vacuum heating element developed for wafer processing in new semiconductor fabrication, is an innovative heating element designed with a graphite core and high-purity silicon carbide coating. The special filament employs the thermal conductivity of the graphite and the durability and protection of SiC, resulting in a stable and energy-efficient heater over time. The SiC Heating Filament is designed to heat wafers uniformly and reach specification, making it an excellent component for high-temperature semiconductor processing, such as epitaxy, diffusion, and annealing.

The SiC Heating Filament is made with high-purity graphite because of graphite's thermal properties and quality electrical properties. Graphite provides the main heating function enabling rapid response and efficient heating under electrical load. The dense high-purity SiC coating protects the filament from possible sources of contamination. The SiC coating protects the wafer from chemical contamination, and oxidation, as well as particles in the chamber, extends the useful life of the filament, and creates a clean chamber environment.

A key quality of the SiC Heating Filament is the ability to deliver uniform heating of the wafer. Temperature variations across the wafer can lead to defects or lost yield. The SiC Heating Filament has excellent thermal conductivity and the solid design of the filament ensures heat will be stable and more uniform, limiting thermal gradients for absolute process control.

SiC Heating Filament is customizable, the electrical resistance value of each filament can be customized for its process tool and operating environment. This customization allows the technology of silicon carbide to control the resistance value of the filament geometry, coating thickness, and material properties. A SiC Heating Filament can fit many different furnace designs with many different wafer sizes and process recipes. This is especially favorable for semiconductor manufacturers, as it allows for current processes to run more efficiently and maintains compatibility with systems already in place. The third feature of performance is durability. In high temperature semiconductor processes, the heating element is exposed to very aggressive chemical environments and repeated thermal cycling.

The applications of Semicorex SiC Heating Filament cover an extensive array of semiconductor device fabrication processes. During epitaxial growth, for example, the heating element provides a stable and uniform substrate temperature for depositing high quality crystalline films.