- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China soi wafer fabrication Manufacturers, Suppliers, Factory

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for soi wafer fabrication,soi wafer,silicon on insulator wafer,soi wafer suppliers,soi wafer thickness, We recognize your enquiry and it can be our honor to work with each mate globally.

soi wafer fabrication, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We now have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our goods are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Hot Products

TaC Tantalum Carbide Coated Plate

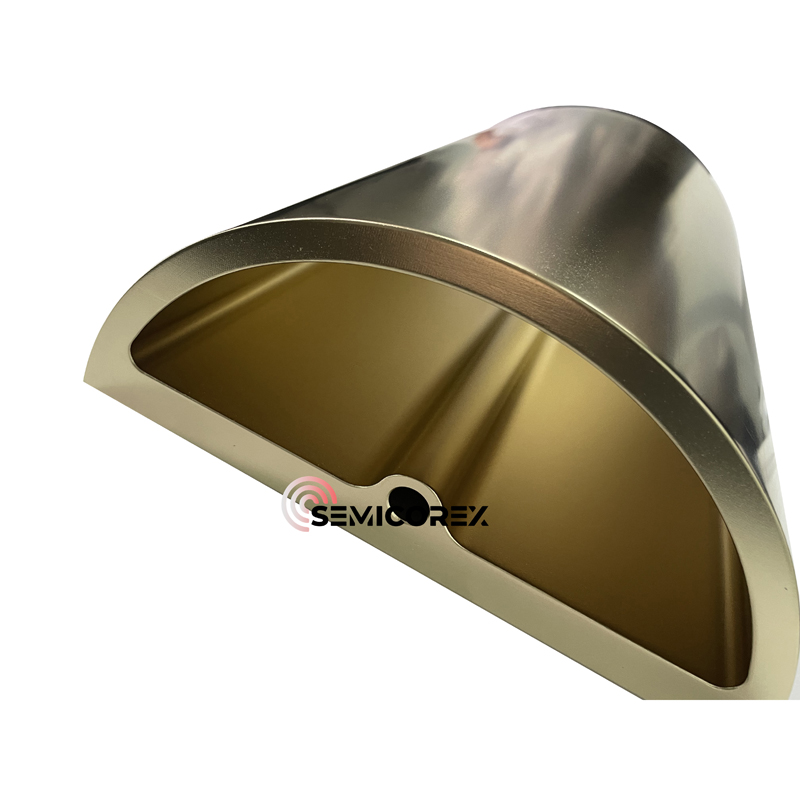

Semicorex TaC Tantalum Carbide Coated Plate is a cutting-edge solution designed to meet the stringent demands of semiconductor manufacturing, particularly in the epitaxial (epi) processing stage. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.High Purity Quartz Bell Jar

Designed to offer unparalleled performance in extreme conditions, Semicorex High Purity Quartz Bell Jar combines exceptional material properties to meet the stringent demands of semiconductor manufacturing.**SiC Ceramic Plate

Semicorex SiC Ceramic Plate offers unmatched performance in environments requiring wear resistance, corrosion resistance, and high-temperature stability. This product is designed for use as lining plates and support parts across a variety of demanding applications.SiC Grinding Media

Semicorex SiC Grinding Media is crafted from silicon carbide ceramic, a material celebrated for its exceptional hardness and durability. Engineered to meet the rigorous demands of various industrial applications, SiC Grinding Media offers unparalleled efficiency and longevity.Silicon Nitride Roller

The Silicon Nitride Roller, presented by Semicorex, is crafted from gas pressure sintered silicon nitride (Si3N4), a high-performance ceramic material.Graphite Top Plates

Semicorex Graphite Top Plates are precision-engineered fixtures designed for secure and reliable handling of hot glass bottles in high-temperature manufacturing environments. Choose Semicorex for unmatched material quality, custom machining capabilities, and consistent performance trusted by leading glass producers worldwide.*