- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Silicon carbide filter Manufacturers, Suppliers, Factory

Our company puts emphasis about the administration, the introduction of talented staff, along with the construction of employees building, seeking hard to boost the standard and liability consciousness of staff members members. Our business successfully attained IS9001 Certification and European CE Certification of Silicon carbide filter,Silicon carbide membranes,Silicon carbide ceramic,SiC membrane,SiC ceramic membrane, We are going to wholeheartedly welcome all clientele during the industry both of those at your home and overseas to cooperate hand in hand, and build a bright potential together.

Silicon carbide filter, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal products. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're planning to let you to get complete acknowledge about our goods and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Hot Products

CVD Epitaxial Deposition In Barrel Reactor

Semicorex CVD Epitaxial Deposition In Barrel Reactor is a highly durable and reliable product for growing epixial layers on wafer chips. Its high-temperature oxidation resistance and high purity make it suitable for use in the semiconductor industry. Its even thermal profile, laminar gas flow pattern, and prevention of contamination make it an ideal choice for high-quality epixial layer growth.Susceptors for MOCVD Reactors

Semicorex's Susceptors for MOCVD Reactors are high-quality products used in the semiconductor industry for various applications such as silicon carbide layers and epitaxy semiconductor. Our product is available in gear or ring shape and is designed to achieve high-temperature oxidation resistance, making it stable at temperatures up to 1600°C.SiC Epitaxy Susceptor

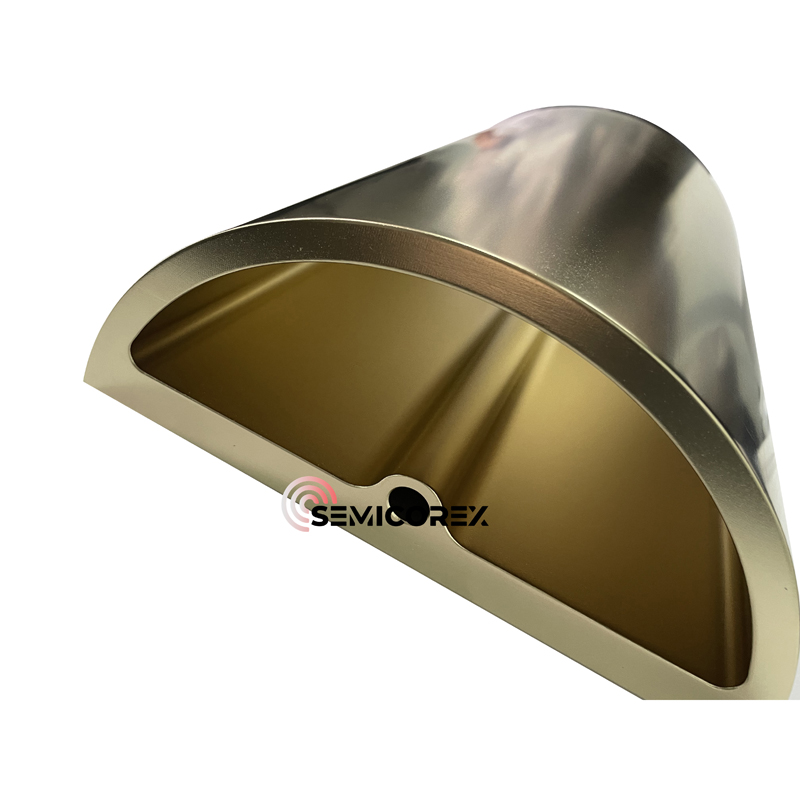

Crafted with precision and engineered for reliability, SiC Epitaxy Susceptor features high corrosion resistance, high thermal conductivity, resistance to thermal shock, and high chemical stability, enabling it to function effectively within an epitaxial atmosphere.Therefore, SiC Epitaxy Susceptor is considered a core and crucial component in MOCVD equipment. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Tantalum Carbide Coating Halfmoon Part

Semicorex Tantalum Carbide Coating Halfmoon Part is a highly specialized component designed for use in the epitaxial deposition process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.SiC-coated Wafer Disc

The Semicorex SiC-coated Wafer Disc represents a leading advancement in semiconductor manufacturing technology, playing an essential role in the complex process of fabricating semiconductors. Engineered with meticulous precision, this disc is crafted from superior SiC-coated graphite, delivering outstanding performance and durability for silicon epitaxy applications. We at Semicorex are dedicated to manufacturing and supplying high-performance SiC-coated Wafer Disc that fuse quality with cost-efficiency.SiC MOCVD Inner Segment

Semicorex SiC MOCVD Inner Segment is an essential consumable for metal-organic chemical vapor deposition (MOCVD) systems used in the production of silicon carbide (SiC) epitaxial wafers. It's precisely designed to withstand the demanding conditions of SiC epitaxy, ensuring optimal process performance and high-quality SiC epilayers.**