- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China icp etching;icp plasma etching;icp etching process;icp etcher;dry etch;dry etching technology for semiconductors;wafer disc;wafer tray;cvd sic coating;dry etcher; Manufacturers, Suppliers, Factory

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for icp etching;icp plasma etching;icp etching process;icp etcher;dry etch;dry etching technology for semiconductors;wafer disc;wafer tray;cvd sic coating;dry etcher;, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

icp etching;icp plasma etching;icp etching process;icp etcher;dry etch;dry etching technology for semiconductors;wafer disc;wafer tray;cvd sic coating;dry etcher;, Our merchandise are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our items or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

Hot Products

Silicon Carbide Coated Barrel Susceptor

Semicorex Silicon Carbide Coated Barrel Susceptor is a high-quality graphite product coated with high-purity SiC, offering exceptional heat and corrosion resistance. It is specifically designed for LPE applications in the semiconductor manufacturing industry.Wafer Holder for ICP Etching Process

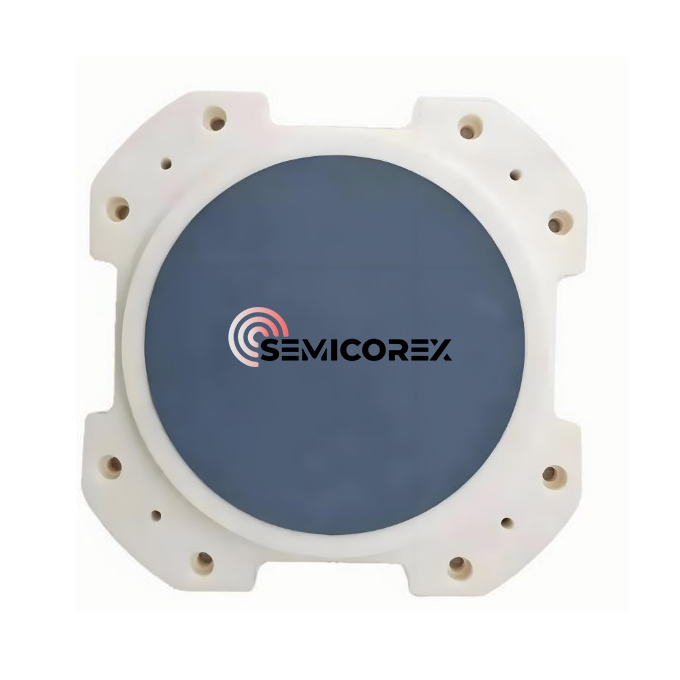

Semicorex's Wafer Holder for ICP Etching Process is the perfect choice for demanding wafer handling and thin film deposition processes. Our product boasts superior heat and corrosion resistance, even thermal uniformity, and optimal laminar gas flow patterns for consistent and reliable results.Susceptor Semiconductor

Semicorex Susceptor Semiconductor, a revolutionary graphite susceptor meticulously crafted to elevate your semiconductor manufacturing to new heights. Engineered with precision and innovation, this susceptor boasts a CVD SiC coating that sets it apart in the industry. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Susceptor Disc

The Semicorex Susceptor Disc is an indispensable tool in Metal-Organic Chemical Vapor Deposition (MOCVD), specifically engineered for supporting and heating semiconductor wafers during the critical process of epitaxial layer deposition. The Susceptor Disc is instrumental in the manufacturing of semiconductor devices, where precise layer growth is paramount. Semicorex’s commitment to market-leading quality, allied with competitive fiscal considerations, cements our eagerness to establish partnerships in fulfilling your semiconductor wafer conveyance requisites.Epitaxy Component

Semicorex Epitaxy Component is a crucial element in the production of high-quality SiC substrates for advanced semiconductor applications, a reliable choice for LPE reactor systems. By selecting Semicorex Epitaxy Component, customers can be confident in their investment and enhance their production capabilities in the competitive semiconductor market.*Al2O3 Vacuum Chucks

Semicorex Al2O3 Vacuum Chucks are microporous ceramic adsorption fixture made from black alumina with a porosity of 35–40%, specifically designed for wafer handling in semiconductor applications. Choosing Semicorex means benefiting from advanced ceramic technology, precision engineering, and reliable product quality that ensure stable performance in demanding cleanroom environments.*