- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Graphite Slide Plate

Semicorex's graphite slide plate has self-lubricating capabilities, which can effectively reduce mechanical running resistance, improve operational efficiency, and minimize mechanical failures caused by insufficient or failed lubrication.

Send Inquiry

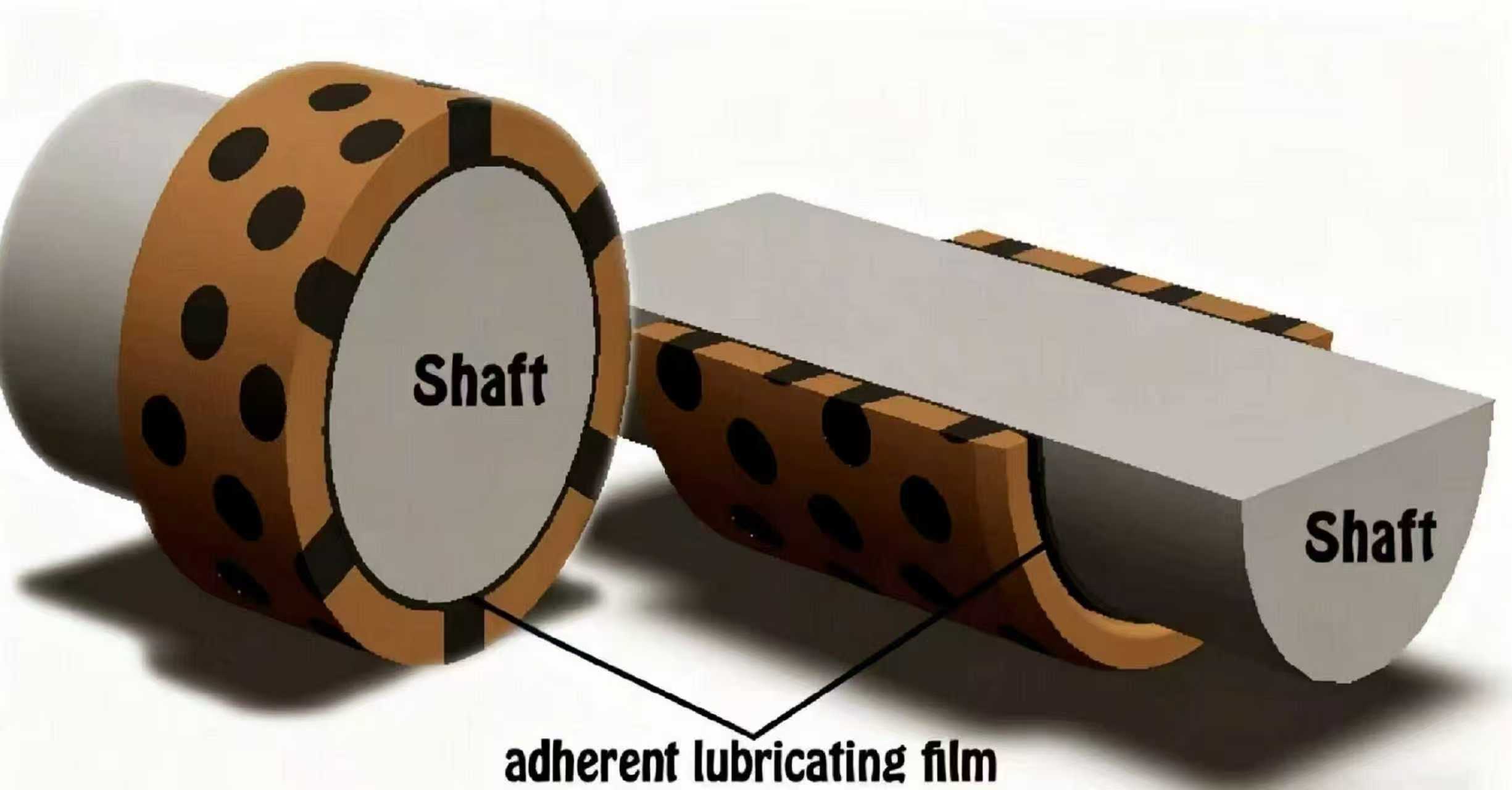

Graphite slide plate is composite component in which graphite plugs are embedded in a metal base. The primary function of the graphite slide plate is to achieve low-friction operation between sliding parts by providing a "self-lubricating" lubricant, thereby reducing the wear of machine parts.

Different from conventional slide plate, graphite slide plate combines the wear resistance of metal and the self-lubricating property of graphite, which has unique advantages in the industrial field. During operation, countless tiny graphite particles are embedded in the micro-pores on the surface of the graphite slide plate. These particles are automatically released to provide lubrication and form a protective film, which minimizes direct metal-to-metal contact. Semicorex’s graphite slide plate is particularly suitable for scenarios where oil or grease injection is difficult or unworkable, and it delivers superior lubrication even in low-speed, high-load operating environments. This oil-free design eliminates the need for frequent manual lubrication and upkeep, significantly lowering both lubricant costs and mechanical maintenance expenses.

Graphite slide plates are commonly available in thicknesses range of 6 to 20 mm and widths range of 50 to 300 mm, and the length can be customized as specific requirements. Normally made of tin bronze or aluminum bronze matrix, with different graphite content to adjust the performance to meet different load requirements.

The application scenarios

1.Machine tool slide-way and sliding block: the top choice for those seeking high precision and long life;

2.Moving parts of injection molding and die-casting machines: prevent oil contamination of products;

3.Automated production lines: allow for stable operation in unattended environments;

4.Equipment in high-temperature and dusty environments: self-lubricating slide plate is more reliable, while grease can easily lose its effectiveness.