- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

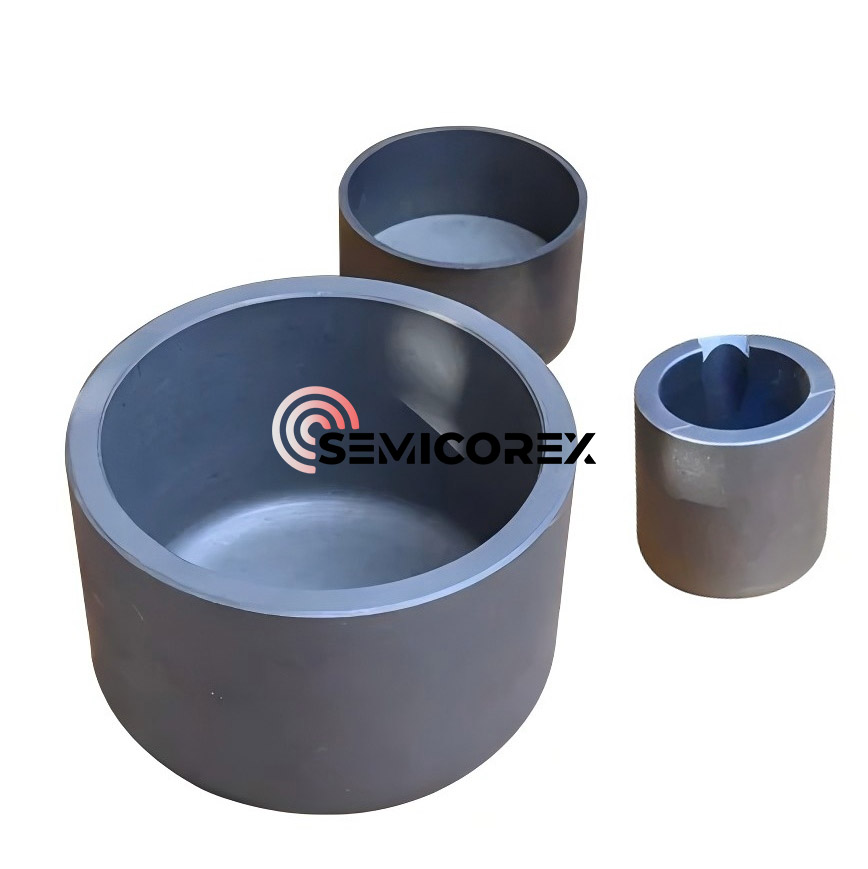

Graphite Bearings

Semicorex graphite bearings has the great advantages on self-lubricating, high-temperature resistance, corrosion resistance, light, etc. It is widely applied in various industries for machine running. Semicorex is committed in supplying qualified products to support our customers.*

Send Inquiry

Bearings are a common sliding parts in the mechanical industry, there are various material, such as metal, non-metal, composite. With properties requirements of the mechanical equipment, graphite bearings are developed based on the metal bearings, main material is graphite. Graphite bearings are different from metal bearings, mainly perform self-lubricating, high-temperature resistance, corrosion resistance, light-weight, etc advantages.

Semicorex Graphite Bearings are high-performance sliding components designed specifically for situations where traditional metal bearings cannot perform, such as in extreme temperatures, corrosive environments, or when lubrication isn't available. These bearings are crafted from high-purity, finely grained graphite and display remarkable self-lubricating abilities, excellent thermal resistance, and impressive chemical stability. Their lightweight design and consistent dimensions make them perfect for challenging applications in chemical processing, semiconductor machinery, metallurgical systems, high-temperature furnaces, and various industrial motion assemblies.

A key feature of graphite bearings is their natural self-lubrication. In contrast to metal bearings that typically need oil or grease for smooth operation, graphite bearings take advantage of carbon's layered molecular structure to create low friction w

ithout additional lubricants. This characteristic helps eliminate concerns about lubricant evaporation, degradation, or contamination—problems often encountered in high-temperature or vacuum settings. Consequently, Semicorex graphite bearings provide reliable performance even during dry runs at high speeds or under heavy loads; thus reducing maintenance needs and enhancing the overall reliability of equipment.

Beyond their thermal stability, graphite bearings also excel in resisting corrosion and chemicals. Graphite remains inert against a broad spectrum of acids, alkalis, and corrosive gases. This property makes it ideal for applications involving pumps, valves, and rotating systems designed to handle chemically aggressive fluids. In situations where metal bearings degrade quickly due to oxidation or chemical reactions, graphite maintains longevity and reliable performance over time. This advantage greatly minimizes downtime while extending the lifespan of equipment—particularly in chemical plants, salt-bath operations, semiconductor wet benches, and gas-handling machinery. Additionally, one of the standout features of graphite is its lightweight nature. With a density significantly lower than that of steel or high-temperature alloys; using graphite bearings leads to reduced rotational inertia along with decreased mechanical load on various assemblies.

Applications

Carbon graphite bearings and bushings are widely applied across various industries such as food and beverage production, textile manufacturing, chemical processing, and fluid handling systems. These components are often used in conveyor bearings, centrifugal pump bearings, submersible pump bushings, gear parts, and other high-performance mechanical assemblies. Their capacity to function without lubrication makes them perfect for sectors where contamination risks must be kept low. Furthermore, they play critical roles in automotive and aerospace industries as well as agricultural machinery—areas that demand consistent reliability even under challenging environmental conditions.