- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

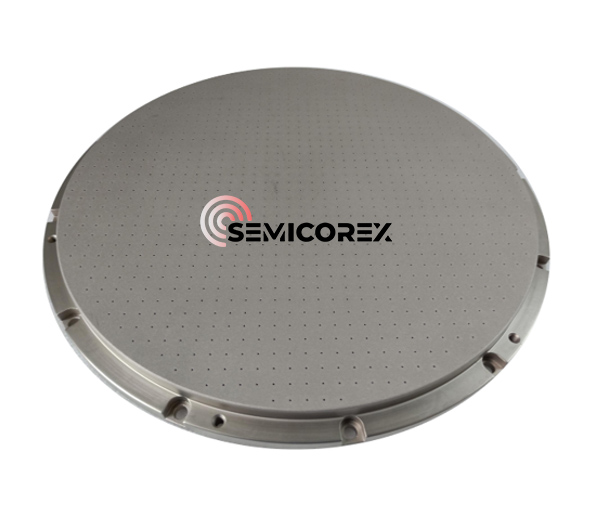

CVD SiC Showerheads

Semicorex CVD SiC Showerheads is a high-purity silicon carbide component designed for gas distribution and electrode functionality in plasma processing chambers. Semicorex is keen to deliver advanced material quality, precision engineering, and reliable performance.*

Send Inquiry

Semicorex CVD SiC Showerheads is an important component of semiconductor plasma processing equipment. The CVD SiC Showerheads provide two primary functions: precise gas distribution and consistent operation of electrodes. The CVD SiC Showerheads are made of high-purity chemical vapor deposited silicon carbide (SiC), and provides various benefits of stability, inertness, and reliability, making it vital technology in advanced plasma etch and deposition equipment.

Uniform gas distribution is important for the uniformity of chemical processes performed with respect to the entire wafer. In that regard, the CVD SiC Showerheads are built with an extremely precise set of uniformly dispersed gas outlets that disperse process gases to the reaction chamber in a uniform manner. The highly controlled gas outlet locations minimize concentration gradients throughout the reaction chamber, while stably navigating the plasma density and providing wafer to wafer uniformity. The CVD SiC Showerheads deliver an efficient, controlled, and consistent gas flow across the entire substrate in order to accurately perform critical plasma processes such as plasma-enhanced chemical vapor deposition (PECVD), plasma etching, and atomic layer deposition (ALD).

As a gas distributor, the CVD SiC Showerheads also functions as an electrode in the plasma chamber that must be able to withstand high RF power, plasma bombardment, and thermally cycle without any degradation in performance. This is possible because of the good electrical conductivity of the CVD SiC that allows it to now function as a stable electrode that enables uniform plasma ignition and control. The minimum purity and dimensional tolerances for both electrodes and gas distribution were a key consideration for both roles of the gas distributor and electrode for the Showerhead.

When considering CVD SiC, material purity was an obvious advantage to using it. The CVD SiC showerheads are manufactured with a chemical vapor deposition process that yields nearly 100% pure silicon carbide without binders or contaminants that could outgas, or otherwise contaminate the wafer environment, thus providing ultra-clean processing to minimize particles and inorganic contamination. As semiconductor device geometries continue to shrink, the contamination-free components of the chamber will be more critical, and CVD SiC performs unmatched in this regard.

Not only is thermal and plasma stability paramount to dependable showerhead performance, but plasma processes can expose components in the chamber to high temperatures and reactive ion bombardment. CVD SiC maintains its structural integrity during these difficult thermal and plasma conditions, while conventional ceramic materials cannot. Its extreme hardness, along with its dense microstructure, offers added erosion resistance and longer showerhead lifetime, requiring less frequent replacements. Overall, this longevity means less maintenance and increased equipment uptimes for semiconductor manufacturers.

Electrical properties of CVD SiC give it another advantage. The controlled conductivity of the showerhead allows for efficient RF coupling and stable plasma - which can be very important to processes that require precise plasma control, like high-aspect-ratio etching or advanced thin-film deposition. The CVD SiC Showerheads act as a stable electrode that allows for uniform electric fields in the chamber and reduces charge effects, which minimizes defects and can assist with process repeatability.