- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

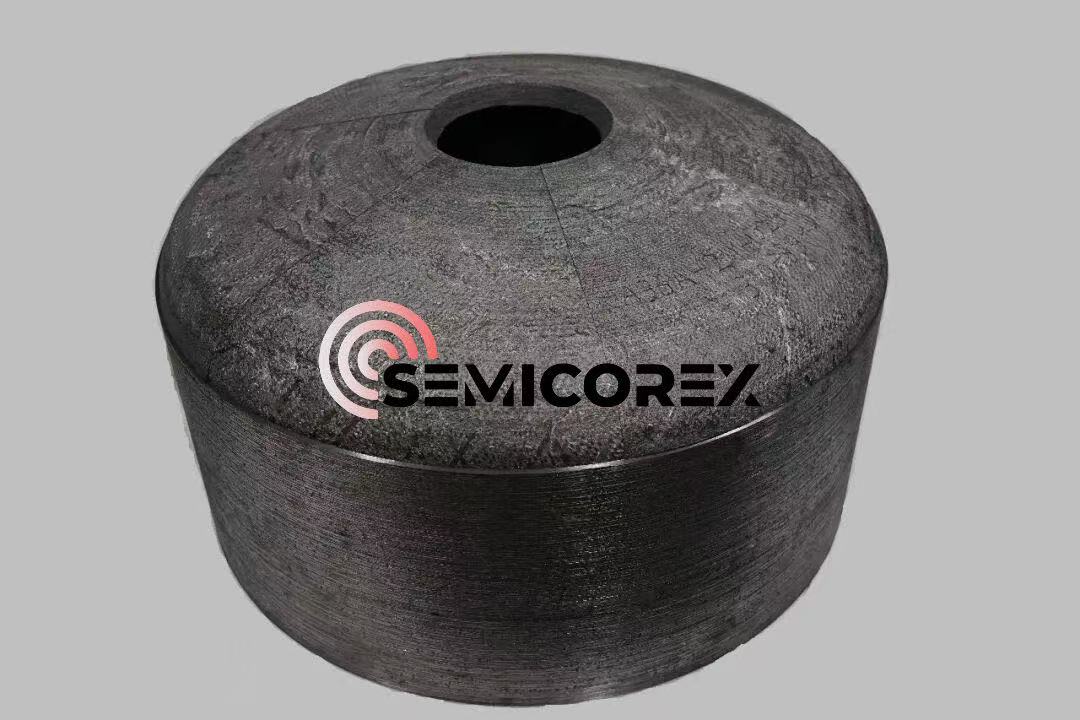

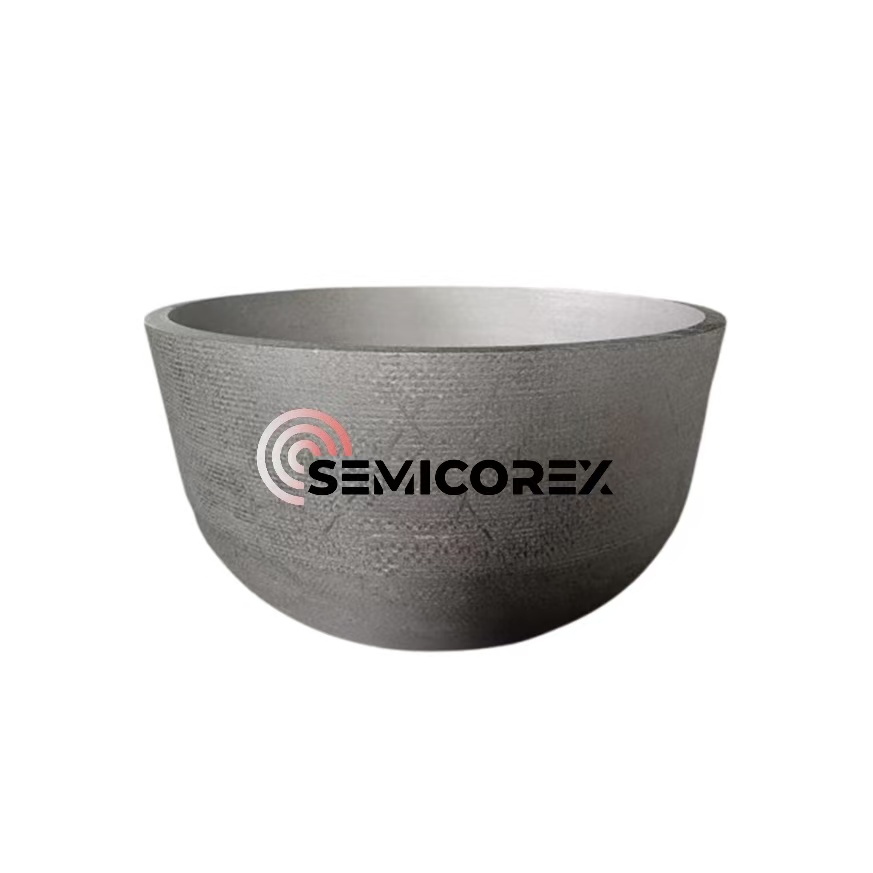

Carbon-carbon Composite Crucibles

Engineered for thermal field systems, Semicorex carbon-carbon composite crucibles are a state-of-the-art solution composed of carbon-carbon composites materials that can withstand high temperatures. Their exceptional strength, superior thermal conductivity, strong chemical stability, and excellent thermal insulation make them ideal for facilitating crystal growth.

Send Inquiry

The carbon-carbon composite crucibles primarily stabilize crucible in the hot zone system of crystal pulling furnaces. This effectively ensures smooth silicon ingot production under high-temperature pulling conditions. Boasting exceptional performance that significantly enhances silicon ingot quality and production efficiency, it is widely used in the semiconductor and photovoltaic industries.

Semicorex carbon-carbon composite crucibles are refined from high-performance carbon fiber preforms via a combination of chemical vapor deposition (CVD) and graphitization. This precise manufacturing process yields crucibles with a dense structure and uniform composition, ensuring stable performance that meets the demands of continuous multi-batch use in crystal pulling furnaces.

The technical index:

|

The technical index |

Unit |

Carbon-carbon Composite Crucibles |

|

Density |

g/m^3 | ≥1.4(It can be customized) |

| Ash content | ppm | <200 |

| Tensile strength | Mpa | ≥80 |

|

Flexural strength |

Mpa | ≥120 |

|

Compression strength |

Mpa | ≥120 |

|

Thermal conductivity |

W/(m*K) |

30-40 |

|

Max. application temperature |

℃ |

Vacuum atmosphere: 2500 Inert Atmosphere: 3000 |

| Treatment temperature |

℃ |

2000-2400 |

Semicorex always prioritizes the core needs of our valued customers, providing them with high-end customized services. To ensure seamless compatibility between the final customized carbon-carbon composite crucibles and various crystal pulling furnace models, we offer customization of crucible specifications and parameters based on customer needs, effectively enhancing equipment operating efficiency and production stability.

Semicorex has set up a comprehensive, high-standard product quality control system. Every our carbon-carbon composite crucible goes through multiple rigorous inspections, each step guided by clear quantitative standards and full professional supervision, thus guaranteeing all delivered units satisfy high-temperature stable operation needs.