- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

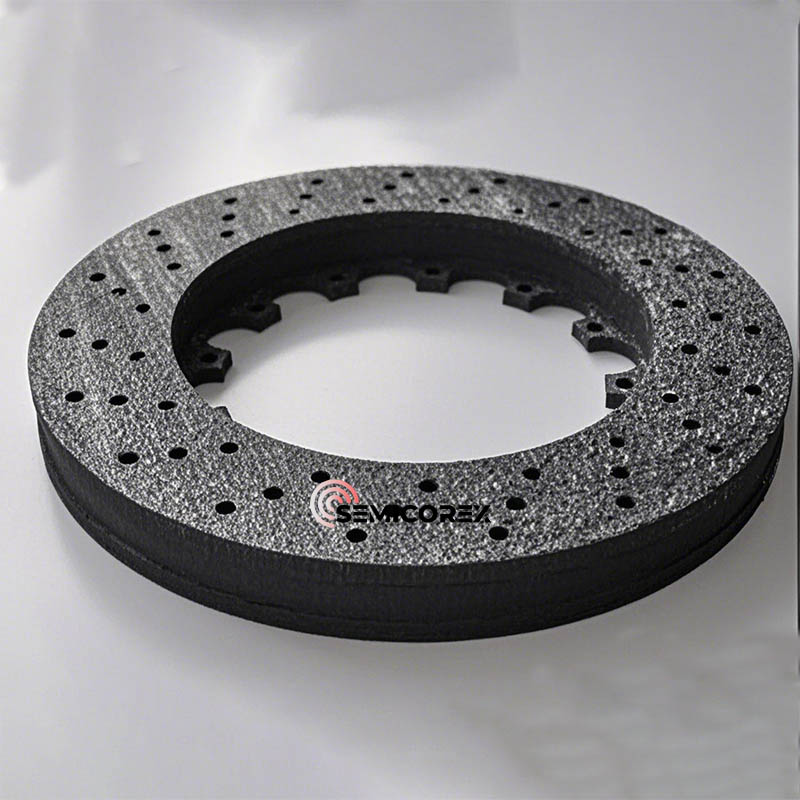

C/SiC Brakes

Semicorex C/SiC brakes offer a lightweight, high-performance braking solution with exceptional heat resistance, durability, and consistent performance, making them ideal for vehicles, and aerospace applications.*

Send Inquiry

Semicorex C/SiC brakes represent the pinnacle of braking technology, offering superior performance, durability, and safety. Designed to address the limitations of traditional cast iron and carbon-carbon (C/C) brakes, C/SiC brakes are widely used in high-performance sports cars, luxury vehicles, and even aerospace applications. Their exceptional heat resistance, lightweight properties, and consistent braking performance make them the preferred choice for both racing professionals and everyday drivers seeking superior stopping power.

The brake disc, an essential component of a vehicle’s braking system, works alongside calipers, brake pads, and brake fluid lines to bring the vehicle to a stop. When the driver presses the brake pedal, hydraulic pressure from the brake fluid is transmitted to the caliper pistons. These pistons then push the brake pads against the rotating brake disc, generating friction. This friction converts kinetic energy into heat, effectively slowing or stopping the vehicle. The effectiveness of this process largely depends on the materials used in the brake disc and pads.

The ultimate evolution in braking technology, C/SiC brakes are created by infusing carbon fiber with silicon carbide. This combination enhances mechanical strength, heat resistance, and oxidation resistance. Unlike C/C discs, C/SiC brakes maintain excellent friction levels in both dry and wet conditions, making them suitable for both high-performance sports cars and regular road vehicles. They offer superior stopping power, significantly reduced weight compared to cast iron, and an extended lifespan without rust or corrosion.

C/SiC brake discs are produced using two primary methods: short-fiber and long-fiber techniques.

Short-Fiber C/SiC Brakes: This method involves blending short carbon fibers with resin to form a powdered mixture, which is then molded and subjected to high-temperature processing. The resulting disc undergoes carbonization and siliconization to achieve its final properties. Short-fiber C/SiC brakes offer high material utilization and a shorter production cycle. However, their mechanical strength and toughness are relatively lower, making them more susceptible to chipping or damage under extreme conditions.

Long-Fiber C/SiC Brakes: This method uses continuous carbon fiber layers combined with a net-reinforced structure. These layers are needle-punched to form an integrated preform, followed by chemical vapor infiltration (CVI) to impregnate carbon molecules into the structure. After multiple deposition cycles, the disc is siliconized and polished to achieve the final C/SiC brake disc. Compared to short-fiber brakes, long-fiber C/SiC brakes offer superior mechanical strength, toughness, and durability. However, their production process is more time-consuming and costly due to repeated deposition and higher material wastage.

Durability and Coatings

One of the potential concerns with C/SiC brake discs is surface oxidation or wear over time, which could lead to cracking or deterioration. However, with the application of advanced protective coatings, these issues can be mitigated, ensuring long-term durability and consistent performance. Proper coatings enhance resistance to oxidation and mechanical wear, making C/SiC brakes a highly reliable braking solution for demanding applications.

C/SiC brake technology represents the future of high-performance braking, combining lightweight construction, exceptional heat resistance, and superior braking consistency. With both short-fiber and long-fiber manufacturing approaches available, C/SiC brakes can cater to various performance and cost requirements. By incorporating protective coatings, they maintain their integrity even under extreme conditions, making them an ideal choice for high-end road vehicles, motorsports, and aviation applications. As advancements continue, C/SiC brakes will play an increasingly important role in the evolution of automotive and aerospace braking systems.