- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

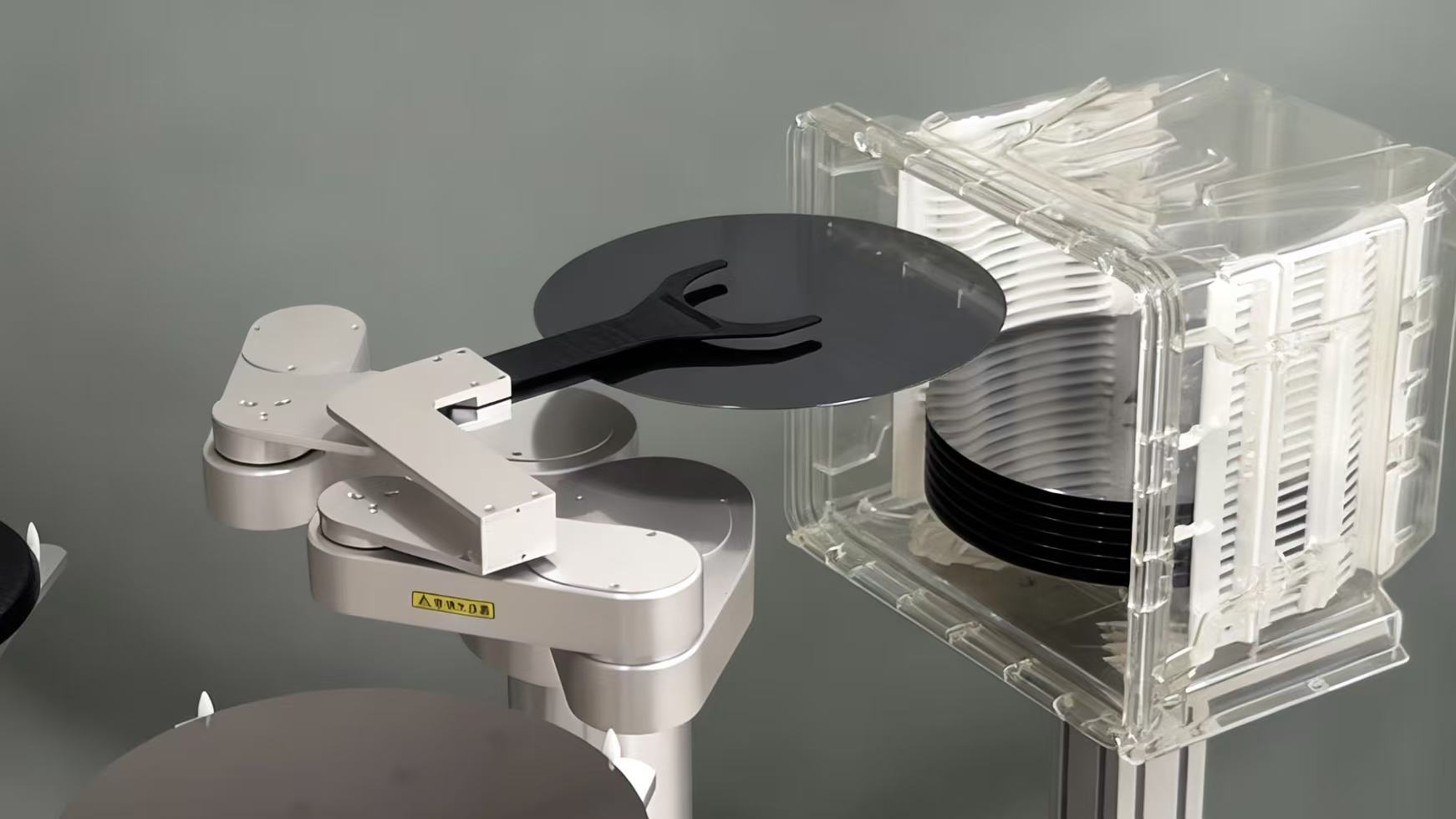

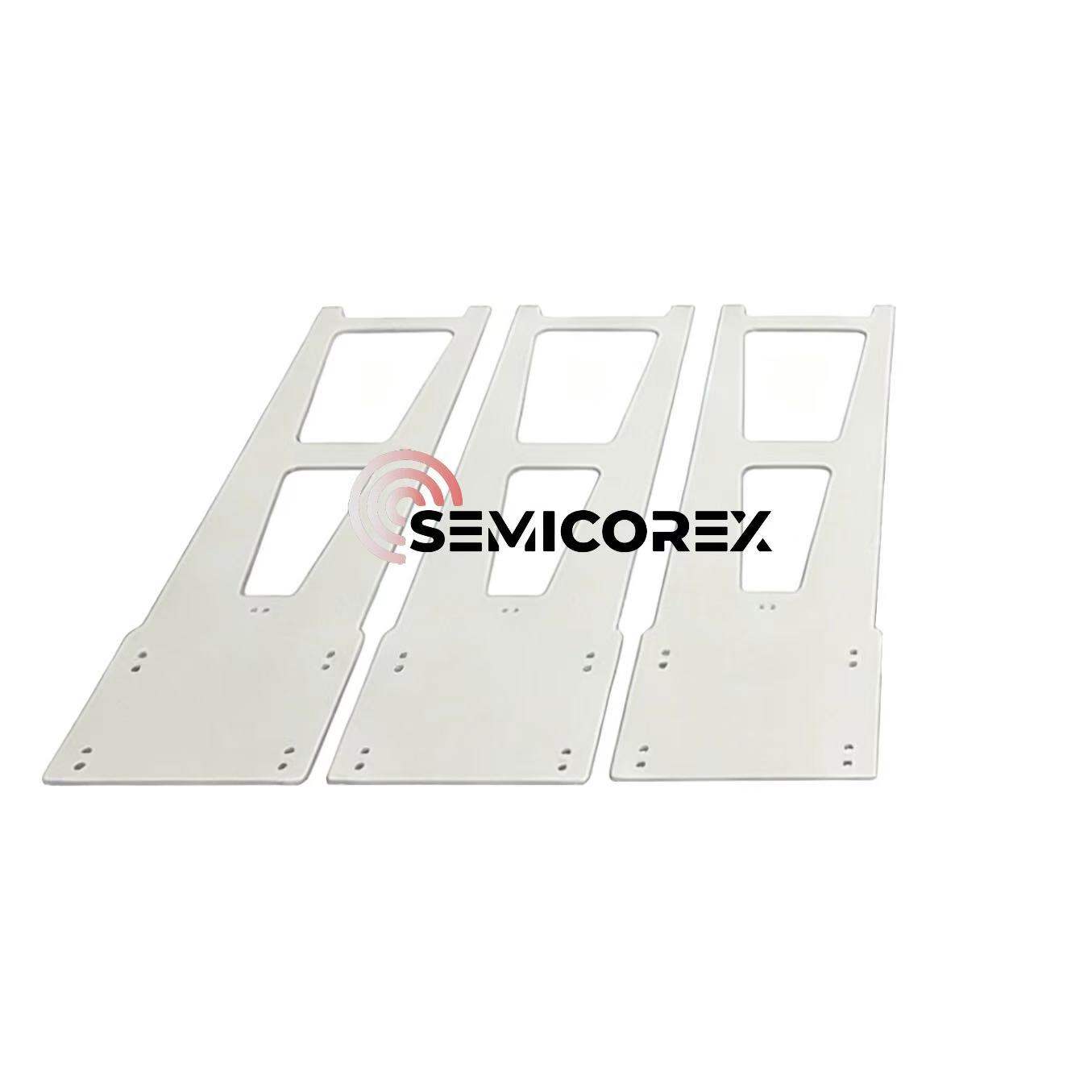

Alumina Ceramic Manipulator

Semicorex alumina ceramic manipulator is a high-performance semiconductor equipment component made of high-purity alumina, engineered specifically for the precise handling of contamination-free wafers. This manipulator has the characteristics of exceptional cleanliness, superior stability, high precision, enhanced efficiency and reliable performance, making it your ideal choice.

Send Inquiry

Alumina ceramic manipulator is also called the alumina ceramic fork and wafer handling end effector. It is installed on the wafer handling robot and is equivalent to the robot's hand. It is used to carry, transport and position semiconductor wafers. Silicon wafers are extremely susceptible to contamination from other particles, so they are typically handled in a vacuum environment to ensure cleanliness. Alumina ceramic manipulators use negative pressure suction to remove wafers and transport semiconductor wafers through the arm's telescoping, rotating, and lifting motions. There are air holes and ventilation grooves inside the alumina ceramic manipulator, which can form a vacuum when pumping air, so that the semiconductor wafers can be adsorbed by light contact without pinching or damaging the semiconductor wafers.

It is well known that the purer the composition of alumina ceramic is, the higher its strength will be. Semicorex alumina ceramic manipulators are made of high-purity alumina ceramic. This results in exceptional mechanical strength and hardness. Their wear resistance far exceeds that of steel and chrome steel, allowing them to maintain surface accuracy over time in high-friction environments, reducing the risk of wafer scratches and making them ideal for high-precision handling. This alumina ceramic manipulator has high resistivity. Its outstanding electrical insulation properties can effectively prevent electrostatic interference, and reduce the risk of particle adsorption to maintain a clean wafer surface. Furthermore, the semiconductor manufacturing process involves complex circuits and high voltage environments within the equipment. The high-resistance alumina ceramic manipulator effectively blocks current conduction, ensuring electrical safety during semiconductor wafer handling. Thanks to the high temperature resistance and thermal stability of alumina ceramic, the manipulator deforms very little during the semiconductor heat treatment process, can accurately position wafers, and avoid precision deviation caused by thermal deformation. Moreover, this material has excellent chemical stability and is highly resistant to corrosion by acids, alkalis, molten metals, etc. It is not easy to react with other substances to release polluting particles, and can effectively protect semiconductor parts from chemical contamination.