- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Specialty Graphite Manufacturers, Suppliers, Factory

Specialty graphite is a kind of artificial graphite that is processed. It is an important material that is indispensable in all aspects of semiconductor and photovoltaic manufacturing process, including crystal growth, ion implantation, epitaxy, etc.

1. Silicon Carbide (SiC) Crystal Growth

Silicon carbide, as a third-generation semiconductor material, is widely used in new energy vehicles, 5G communications, and other fields. In the 6-inch and 8-inch SiC crystal growth process, isostatic graphite is primarily used to manufacture the following key components:

Graphite crucible: This can be used to synthesize SiC powder feedstock and also assist in crystal growth at high temperatures. Its high purity, high-temperature resistance, and thermal shock resistance ensure a stable crystal growth environment.

Graphite heater: This provides uniform heat distribution, ensuring high-quality SiC crystal growth.

Insulation tube: This maintains temperature uniformity within the crystal growth furnace and reduces heat loss.

2. Ion Implantation

Ion implantation is a key process in semiconductor manufacturing. Isostatic graphite is primarily used to manufacture the following components in ion implanters:

Graphite getter: This absorbs impurity ions in the ion beam, ensuring ion purity.

Graphite focusing ring: This focuses the ion beam, improving ion implant accuracy and efficiency. Graphite substrate trays: Used to support silicon wafers and maintain stability and consistency during ion implantation.

3. Epitaxy Process

The epitaxy process is a critical step in semiconductor device manufacturing. Isostatically pressed graphite is primarily used to manufacture the following components in epitaxy furnaces:

Graphite trays and susceptors: Used to support silicon wafers, providing stable support and uniform heat conduction during the epitaxy process.

4. Other Semiconductor Manufacturing Applications

Isostatically pressed graphite is also widely used in the following semiconductor manufacturing applications:

Etching Process: Used to manufacture graphite electrodes and protective components for etchers. Its corrosion resistance and high purity ensure stability and precision in the etching process.

Chemical Vapor Deposition (CVD): Used to manufacture graphite trays and heaters within CVD furnaces. Its high thermal conductivity and high-temperature resistance ensure uniform thin film deposition.

Packaging Testing: Used to manufacture test fixtures and carrier trays. Its high precision and low contamination ensure accurate test results.

Advantages of graphite parts

High purity:

Using high-purity isostatically pressed graphite material with extremely low impurity content, it meets the stringent material purity requirements of semiconductor manufacturing. The company's own purification furnace can purify graphite to below 5ppm.

High precision:

With advanced processing equipment and mature processing technology, it ensures that the product's dimensional accuracy and form and position tolerances reach the micron level.

High performance:

The product has excellent high temperature resistance, corrosion resistance, radiation resistance, high thermal conductivity and other properties, meeting the various harsh working conditions of semiconductor manufacturing.

Customized service:

Customized product design and processing services can be provided according to customer needs to meet the needs of different application scenarios.

Types of graphite products

(1) Isostatic graphite

Isostatic graphite products are produced by cold isostatic pressing. Compared with other forming methods, the crucibles produced by this process have excellent stability. The graphite products required for SiC single crystals are all large in size, which will lead to uneven purity on the surface and inside of the graphite products, which cannot meet the use requirements. In order to meet the deep purification requirements of large-sized graphite products required for SiC single crystals, a unique high-temperature thermochemical pulse purification process should be adopted to achieve deep and uniform purification of large-sized or special-shaped graphite products, so that the purity of the product surface and core can meet the use requirements.

(2) Porous graphite

Porous graphite is a type of graphite with high porosity and low density. In the SiC crystal growth process, porous graphite plays a significant role in improving mass transfer uniformity, reducing the occurrence rate of phase change and improving the crystal shape.

The use of porous graphite improves the temperature and temperature uniformity of the raw material area, increases the axial temperature difference in the crucible, and also has a certain effect on weakening the recrystallization of the raw material surface; in the growth chamber, porous graphite improves the stability of material flow throughout the growth process, increases the C/Si ratio of the growth area, helps to reduce the probability of phase change, and at the same time, porous graphite also plays a role in improving the crystal interface.

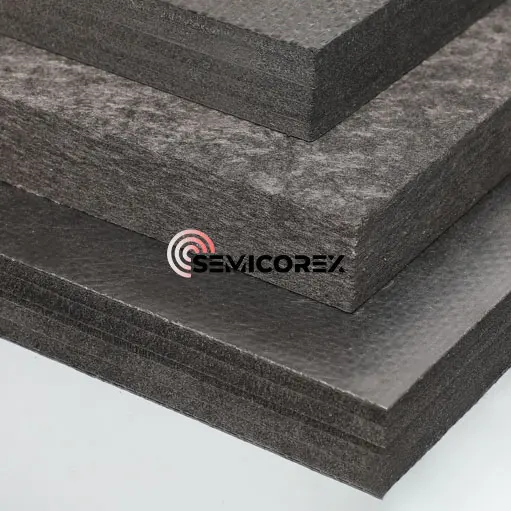

(3) Felt

Soft felt and hard felt both play the role of important thermal insulation materials in SiC crystal growth and epitaxial links.

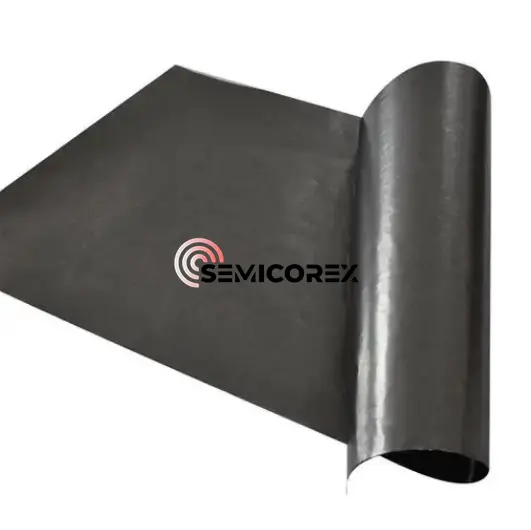

(4) Graphite foil

Graphite paper is a functional material made from high-carbon flake graphite through chemical treatment and high-temperature rolling. It has high thermal conductivity, electrical conductivity, flexibility, and corrosion resistance.

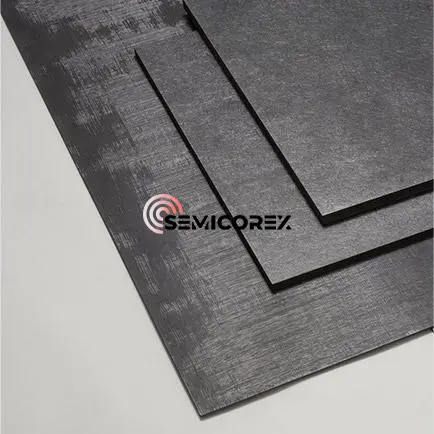

(5) Composite materials

Carbon-carbon thermal field is one of the core consumables in photovoltaic single crystal furnace production.

Semicorex Production

Semicorex make graphite with small-batch, customized production methods. The small-batch production makes the products more controllable. The entire process is controlled by Programmable Logic Controllers (PLCs), the detailed process data were recorded, enabling complete lifecycle traceability.

During the entire roasting process, the consistency achieved in resistivity across different locations, and the tight temperature control maintained. This ensures the homogeneity and reliability of the graphite materials.

Semicorex utilize fully isostatic pressing technology, which is different from other suppliers; it means the graphite is ultra uniform itself and is proven particularly important in epitaxial processes. The comprehensive material uniformity tests were conducted, including density, resistivity, hardness, bending strength, and strength across different samples.

- View as

Graphite Rigid Felt

Semicorex Graphite Rigid Felt is a high-performance material designed for high-temperature applications, offering exceptional compressive strength and superior thermal insulation. Let Semicorex be your trusted partner in achieving higher industrial goals.*

Read MoreSend InquiryGlass-like Carbon Coated Rigid Felt

The Glass-like Carbon Coated Rigid Felt, a signature product of Semicorex,consists of a Carbon Fiber rigid felt substrate enveloped by a glass-like carbon coating, combining the inherent strength of the felt with the exceptional surface properties of the glass-like carbon. Together, they create a material that stands out for its performance under extreme conditions.**

Read MoreSend InquiryC/C Composite Crucible

Semicorex C/C Composite Crucible from Semicorex is a high-performance crucible engineered for crystal growth, offering exceptional thermal stability, durability, and chemical resistance. Choosing Semicorex ensures you receive a reliable, precision-manufactured product tailored to meet the rigorous demands of high-temperature crystal growth applications.*

Read MoreSend InquiryGraphite Foil Roll

Semicorex Graphite Foil Roll is an advanced material made from expanded natural graphite, designed to meet the precise demands of high-temperature applications. With resilience, chemical inertness, and superior thermal properties, this product stands out as an essential component in various industries including semiconductor, solar, and ceramics.**

Read MoreSend InquiryCarbon Carbon Composites

Semicorex Carbon Carbon Composites are advanced materials that offer exceptional lightweight strength, high thermal conductivity, and remarkable resistance to harsh conditions. Choose Semicorex for our unparalleled quality and innovative engineering, ensuring you receive reliable and high-performance solutions tailored to your specific needs.*

Read MoreSend InquiryFlexible Graphite Foil

Semicorex Flexible Graphite Foil is a high performance, flexible material designed for sealing and gasketing applications. When you choose a Semicorex product, you get superior quality and reliability, ensuring your most stringent industry standards are met.*

Read MoreSend Inquiry