- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Quartz Manufacturers, Suppliers, Factory

Quartz is a mineral composed of silicon dioxide, with the chemical formula SiO2. Pure quartz is colorless and transparent, but can appear in various colors due to trace amounts of pigment ions, finely dispersed inclusions, or the presence of color centers, which reduces its transparency. It has a vitreous luster and a greasy sheen on the fracture. Quartz products are widely used in semiconductor manufacturing, and high-purity quartz products are important consumables in wafer production.

The manufacturing process for quartz products is very complex. Quartz sand is first melted and smelted into quartz ingots, which are then heat-formed and cold-processed into quartz products. Based on the process and processing technology, quartz products can be divided into two types: fire-processed and machine-processed. Fire-processing is primarily used in the photovoltaic industry and has lower profit margins. Machine processing relies on different methods and combinations to complete shaping and polishing, primarily producing high-value-added products that require high consistency and stability, and is often used in the semiconductor industry.

Quartz components used in semiconductors can generally be divided into high-temperature and low-temperature components, respectively used in high-temperature processes such as diffusion and oxidation, and low-temperature processes such as etching, packaging, photolithography, and cleaning. Quartz components used in high-temperature processes, as they must operate continuously for hours at temperatures exceeding 1,000 degrees Celsius, require high-temperature resistance, excellent thermal stability, and resistance to deformation. The presence of hydroxyl groups alters the bonding structure of silicon dioxide, the primary component of quartz products, thereby reducing the material's thermal stability and significantly diminishing its high-temperature resistance. Therefore, quartz components used in high-temperature processes require dehydroxylation. Furthermore, these components must exhibit corrosion resistance, excellent light transmittance, and low impurity content. Quartz components used in low-temperature processes, on the other hand, do not require high-temperature processing, so the hydroxyl content of the quartz material is not a requirement.

Quartz Boat

Quartz Tube

Quartz Crucible

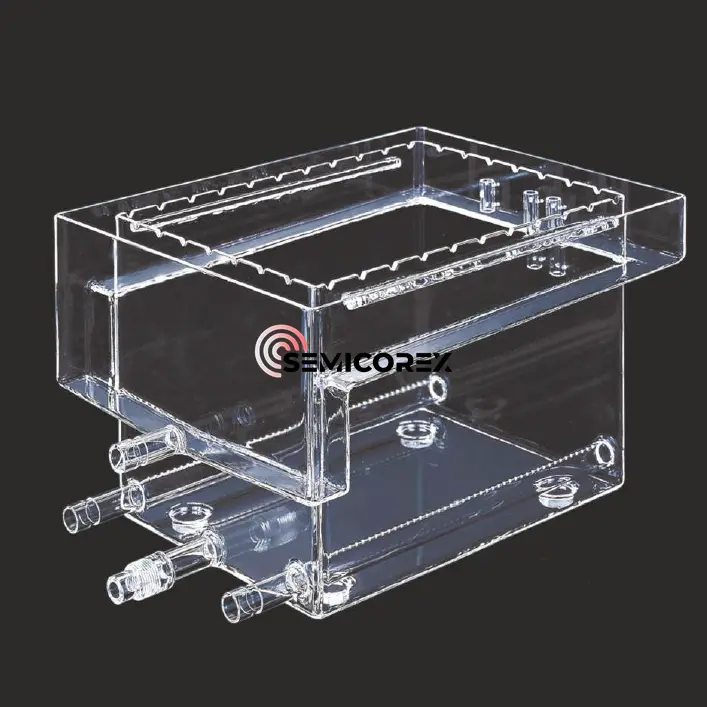

Quartz Tank/Bath

Quartz Pedestal

Quartz Bell Jar

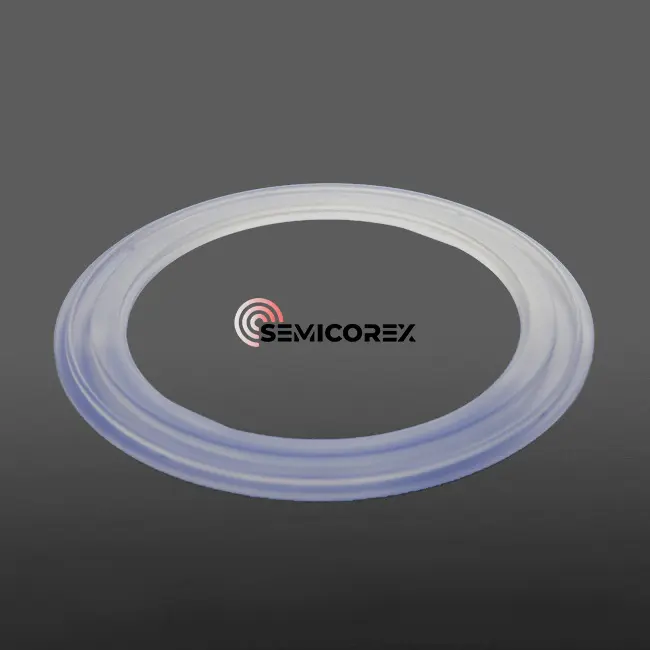

Quartz Ring

Other Quartz Parts

- View as

High Purity Quartz Crucible

Semicorex High Purity Quartz Crucible meticulously crafted from high-purity quartz, is essential for extracting single-crystal silicon—an indispensable component in modern electronics and renewable energy technologies.**

Read MoreSend InquiryQuartz Sand

Semicorex is a leading provider of ultra-high purity quartz sand, offering products with ≥99.995% SiO2 content. Our quartz sand stands out for its exceptional purity, ultra-low alkali metal content, and customizable aluminum content.**

Read MoreSend InquiryQuartz Tank for Wet Processing

Semicorex Quartz Tank for Wet Processing, also known as quartz bath, is particularly critical in wet processes used for wafer fabrication.**

Read MoreSend InquiryQuartz Diffusion Tube

Semicorex Quartz Diffusion Tube is indispensable in the semiconductor wafer manufacturing industry, particularly during the critical processes of thermal oxidation and annealing.**

Read MoreSend InquiryQuartz Diffusion Boat

Semicorex Quartz Diffusion Boat, also referred to as quartz carrier or quartz wafer boat, is specifically designed to hold semiconductor wafers during critical processes such as chemical vapor deposition (CVD), thermal oxidation, and annealing.**

Read MoreSend InquiryFused Quartz Ring

The Fused Quartz Ring from Semicorex is a critical component designed specifically for the semiconductor etching process with exceptional purity, thermal stability, and chemical resistance. **

Read MoreSend Inquiry