- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

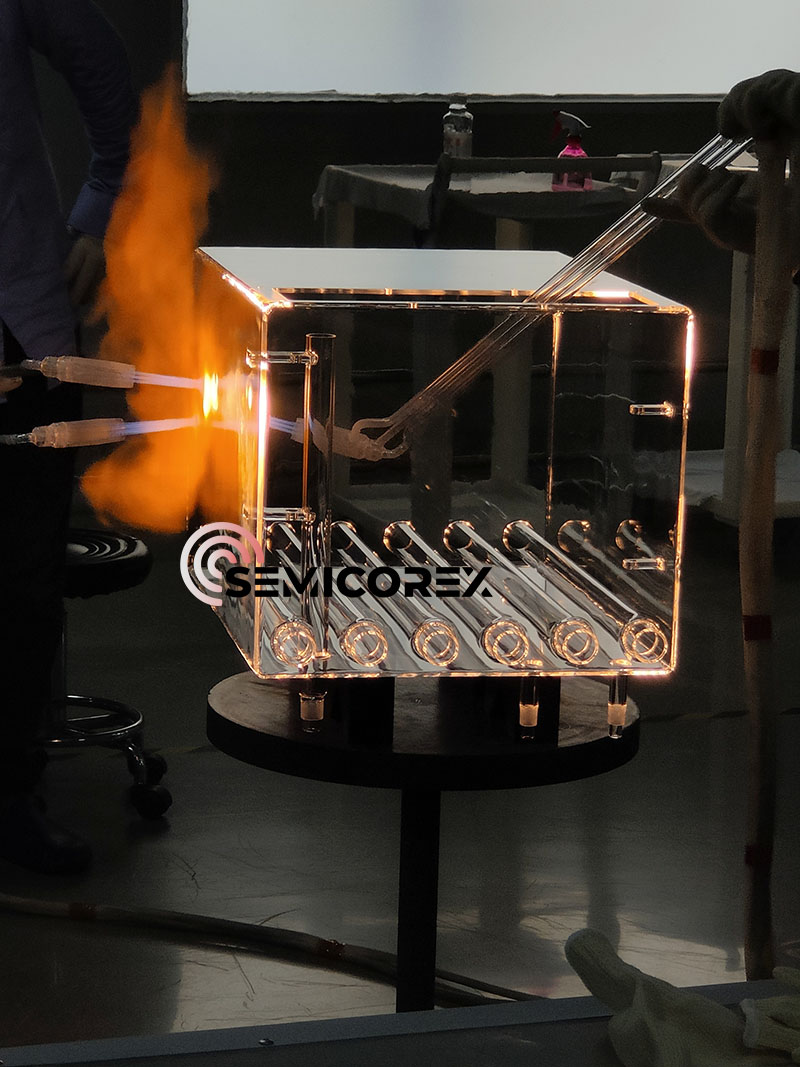

Quartz Cold Trap

Semicorex Quartz Cold Trap is the common glassware used in laboratory. Semicorex is specialized in precious machining for quartz products based on customers’ requirements.*

Send Inquiry

Semicorex Quartz Cold Trap is specifically designed to collect and prevent contamination, and providing protection to vacuum pumps and/or analytical instruments. It is made of high-purity fused quartz, which has extremely high thermal stability, chemical resistance and physical durability, making it an indispensable piece of equipment for research laboratories with exacting standards of accuracy and reliability. By condensing and collecting volatile compounds prior to reaching sensitive equipment, the quartz cold trap allows for

cleaner processing, increased lifespan of systems, and more accurate experimental results.

Quartz possesses several advantages as a construction material for cold traps due to its exceptional physical and chemical properties. The extremely low thermal expansion coefficient of quartz allows it to tolerate rapid temperature changes, including exposure to low-temperature cryogenic cooling agents like dry ice, liquid nitrogen, or chilled circulating liquids. Unlike conventional glass that will fracture or fail during highly increased thermal stress, quartz will not lose its physical characteristics when subjected to repeated freeze-thaw cycles. Because of these properties, quartz cold traps are well-suited for laboratories involved with solvent recovery, freeze drying, vacuum distillation or vapor-sensitive experimentation that depend on constant low-temperature operation.

Chemical inertness is a further area in which the use of Quartz Cold Traps holds a significant benefit. The high-purity nature of quartz makes it resistant to degradation as well as to any reactive interaction with the majority of solvents, acids, organic vapours, and corrosive gases. Thus, the materials being collected in the trap are assured of being free from contaminants and that no undesired reactions between the trapped materials and the trap itself will occur. In the case of processes where sample integrity is extremely important, i.e. in the fields of analytical chemistry, materials synthesis, or semiconductor-related research, having a high degree of purity in the materials that are collected in the cold trap is critical in order to maintain consistent experimental conditions and, therefore, the validity of the resulting data. The smooth internal surface of the quartz cold trap reduces the amount of material that will adhere to it and makes it easy to clean out, allowing the cold trap and the entire system to perform to their optimum level for longer than they would normally be expected to with continued use.

The optical transparency of quartz offers advantages beyond those provided by normal glass. Unlike glass, quartz is optically transparent at UV, visible, and Infrared wavelengths, so the researcher has the ability to visually observe the pattern of condensation, the frost formation, and the collection of the materials that have been trapped. This ability to monitor these visual processes allows a researcher to directly evaluate the efficiency of the liquid coolant system being used, as well as an accurate assessment of the system’s ultimate performance and the amount of capacity currently available. Additionally, this capability aids in determining the source of potential blockage in the trap or a malfunctioning component of the overall vacuum system without having to disassemble the equipment.

With many different types of quartz cold traps available to accommodate many types of laboratory systems and scientific processes, a wide range of quartz cold traps are designed to meet the different types of experimental requirements. Straight tubes, U-shaped traps, spiral coils, and multi-chamber traps can all be custom fabricated for precision according to experimental needs. Either standard ground-glass joints or flanges, or customized connection interfaces allow for seamless insertion into either pre-existing vacuum lines or distillation apparatus. The trap can be made with reinforced wall thicknesses and/or larger volume chambers to maximize vapor capture efficiency for demanding applications with high flow rates and/or very high vacuum levels.

Because fused quartz can withstand high heat and cryogenic low temperatures, quartz provides additional utility beyond merely being a condensable trapping method. Some laboratories utilize quartz cold traps as intermediate heat exchangers, optical instruments in cryogenic spectroscopy systems, or as barriers against corrosive gases and/or particulate-fouled gases. The strength of fused quartz provides a long service life with minimal maintenance by allowing these traps to endure severe operational conditions without distortion, breakage, and/or loss of their sealing ability.