- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Ceramics Insulator Manufacturers, Suppliers, Factory

We'll dedicate ourselves to offering our esteemed customers together with the most enthusiastically thoughtful solutions for Ceramics Insulator,Carbide Seal Ring,Bearing Seal,Graphite Bush Rings,Sic Seal Ring, "Passion, Honesty, Sound service, Keen cooperation and Development" are our objectives. We have been here anticipating good friends all over the environment!

Ceramics Insulator, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Hot Products

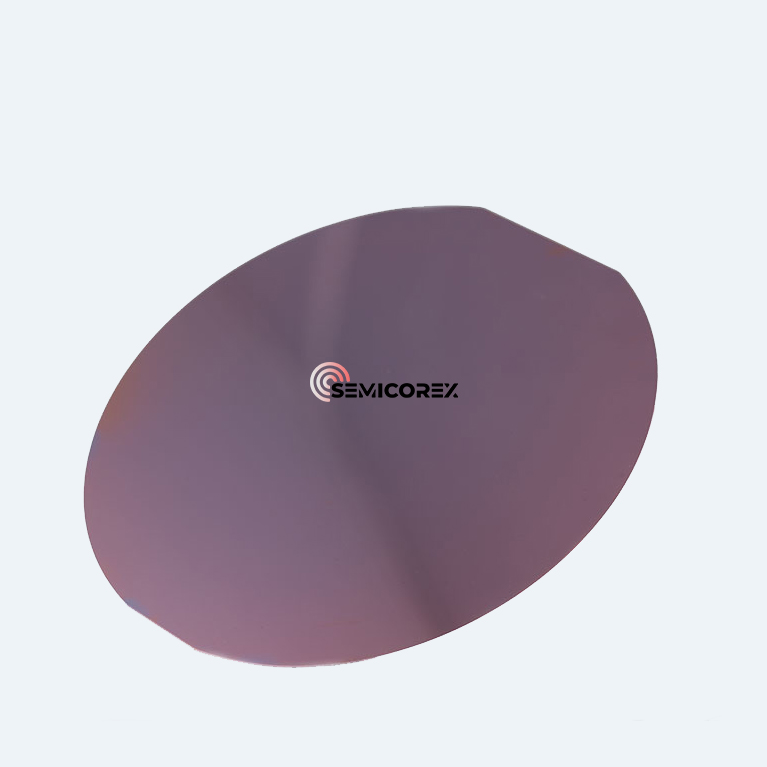

SiC Coated PSS Etching Carrier

Wafer carriers used in epixial growth and wafer handling processing must endure high temperatures and harsh chemical cleaning. Semicorex SiC Coated PSS Etching Carrier engineered specifically for these demanding epitaxy equipment applications. Our products have a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner in China.Gas Inlet Ring for Semiconductor Equipment

Semicorex is a large-scale manufacturer and supplier of Silicon Carbide Coated Graphite Susceptor in China. We focus on semiconductor industries such as silicon carbide layers and epitaxy semiconductor. Our Gas Inlet Ring for Semiconductor Equipment has a good price advantage and cover many of the European and American markets. We look forward to becoming your long-term partner in China.Second Half Parts for Lower Baffles in Epitaxial Process

Semicorex Second Half Parts for Lower Baffles in Epitaxial Process, meticulously engineered components designed to revolutionize the performance of your semiconductor devices. Specifically tailored for the intake system of LPE reactors, these semi-cylindrical fittings play a pivotal role in enhancing the epitaxial growth process. Semicorex is committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.Alumina Ceramic Wafer Chucks

Semicorex Alumina Ceramic Wafer Chucks not limited to a single industry; their unique properties make them suitable for a wide range of applications. In the semiconductor sector, they are used for holding wafers during chip fabrication. In the chemical industry, their corrosion resistance makes them ideal for handling aggressive substances. Environmental applications benefit from their stability and resistance to wear, while their mechanical properties are leveraged in the development of functional materials.We at Semicorex are dedicated to manufacturing and supplying high-performance Alumina Ceramic Wafer Chucks that fuse quality with cost-efficiency.Silicon Carbide Ceramic Structural Parts

Semicorex Silicon Carbide Ceramic Structural Parts, gained from grains of silicon carbide bonded together by sintering, find extensive usage in the automotive, mechanical, chemical, semiconductor, space technology, microelectronics, and energy sectors, fulfilling critical roles in diverse applications across these industries. Due to their remarkable properties, Silicon Carbide Ceramic Structural Parts have become an ideal material for harsh conditions characterized by high temperatures, high pressures, corrosion, and abrasion, providing reliable performance and longevity in challenging operational environments.**Silicon Carbide Sleeve

Semicorex Silicon Carbide Sleeve is commonly used as a wear-resistant and corrosion-resistant liner for equipment such as cylinders, pumps, valves, sliding bearings, and grinder drums.