- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

SiC Crystals Prepared by PVT Method

2025-11-05

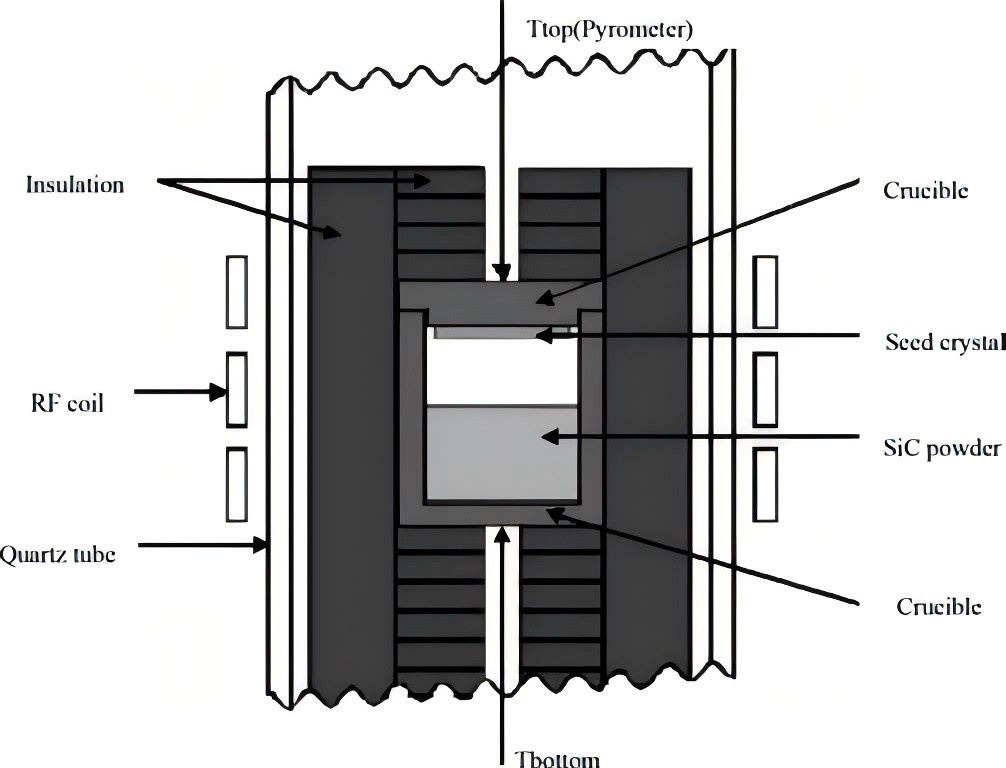

The mainstream method for preparing silicon carbide single crystals is the physical vapor transport (PVT) method. This method mainly consists of a quartz tube cavity, a heating element (induction coil or graphite heater), graphite carbon felt insulation material, a graphite crucible, a silicon carbide seed crystal, silicon carbide powder, and a high-temperature thermometer. The silicon carbide powder is located at the bottom of the graphite crucible, while the seed crystal is fixed at the top. The crystal growth process is as follows: the temperature at the bottom of the crucible is raised to 2100–2400 °C through heating (induction or resistance). The silicon carbide powder at the bottom of the crucible decomposes at this high temperature, producing gaseous substances such as Si, Si₂C, and SiC₂. Under the influence of the temperature and concentration gradients within the cavity, these gaseous substances are transported to the lower-temperature surface of the seed crystal and gradually condense and nucleate, ultimately achieving the growth of the silicon carbide crystal.

The key technical points to note when growing silicon carbide crystals using the physical vapor transport method are as follows:

1)The purity of the graphite material inside the crystal growth temperature field must meet the requirements. The purity of graphite parts should be less than 5×10-6, and that of the insulation felt should be less than 10×10-6. Among these, the purity of B and Al elements should be below 0.1×10-6, as these two elements will generate free holes during silicon carbide growth. Excessive amounts of these two elements will lead to unstable electrical properties of silicon carbide, affecting the performance of silicon carbide devices. At the same time, the presence of impurities may lead to crystal defects and dislocations, ultimately affecting the quality of the crystal.

2)The seed crystal polarity must be correctly selected. It has been verified that the C(0001) plane can be used to grow 4H-SiC crystals, and the Si(0001) plane is used to grow 6H-SiC crystals.

3)Use off-axis seed crystals for growth. The optimal angle of the off-axis seed crystal is 4°, pointing towards the crystal orientation. Off-axis seed crystals can not only change the symmetry of crystal growth and reduce defects in the crystal, but also allow the crystal to grow along a specific crystal orientation, which is beneficial for preparing single-crystal crystals. At the same time, it can make the crystal growth more uniform, reduce internal stress and strain in the crystal, and improve crystal quality.

4)Good seed crystal bonding process. The back side of the seed crystal decomposes and sublimates at high temperature. During crystal growth, hexagonal voids or even microtube defects can be formed inside the crystal, and in severe cases, large-area polymorphic crystals can be generated. Therefore, the back side of the seed crystal needs to be pretreated. A dense photoresist layer with a thickness of about 20 μm can be coated on the Si surface of the seed crystal. After high temperature carbonization at about 600 °C, a dense carbonized film layer is formed. Then, it is bonded to a graphite plate or graphite paper under high temperature and pressure. The seed crystal obtained in this way can greatly improve the crystallization quality and effectively inhibit the ablation of the back side of the seed crystal.

5) Maintain the stability of the crystal growth interface during the crystal growth cycle. As the thickness of silicon carbide crystals gradually increases, the crystal growth interface gradually moves towards the upper surface of the silicon carbide powder at the bottom of the crucible. This causes changes in the growth environment at the crystal growth interface, leading to fluctuations in parameters such as the thermal field and carbon-silicon ratio. Simultaneously, it reduces the atmospheric material transport rate and slows down the crystal growth speed, posing a risk to the continuous and stable growth of the crystal. These problems can be mitigated to some extent by optimizing the structure and control methods. Adding a crucible motion mechanism and controlling the crucible to move slowly upwards along the axial direction at the crystal growth rate can ensure the stability of the crystal growth interface growth environment and maintain a stable axial and radial temperature gradient.

Semicorex offers high-quality graphite components for SiC crystal growth. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com