- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

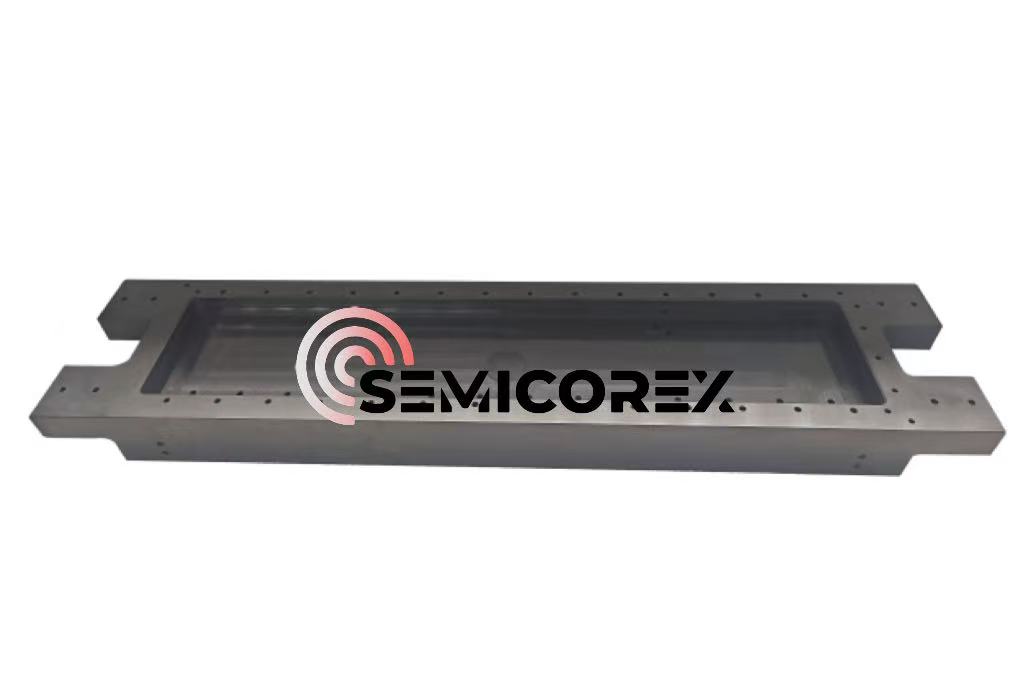

What is the silicon carbide aerostatic slideway?

2025-11-10

Silicon carbide aerostatic slideway is an advanced guideway system that combines the material properties of silicon carbide and aerostatic technology. Servicing as the optimal solution for high-precision, high-reliability and long-term motion systems, silicon carbide aerostatic slideway is widely used in the field like cutting-edge manufacturing, scientific research instruments.

From the material perspective, high-performance silicon carbide material exhibits exceptional stability, relying on a suite of fabulous inherent properties. These properties specifically include high rigidity, strong chemical stability, ultra-low coefficient of thermal expansion, excellent wear resistance as well as superb corrosion resistance, all of which render it a preferred material for a wide range applications in state-of-the-art manufacturing fields. Fabricated from high-purity silicon carbide, the silicon carbide aerostatic slideway inherits the aforementioned material advantages inherently, enabling stable operation even under complex and harsh operating conditions.

In terms of its structure, silicon carbide aerostatic slideway adopts a non-contact structure. By utilizing the gas hybrid hydrostatic and hydrodynamic effect, silicon carbide aerostatic slideway achieves smooth movement free from friction and vibration. After undergoing precision machining, it demonstrates exceptional straightness and flatness specifications. Combined with its non-contact operation, this precision results in an extremely low friction coefficient, which effectively minimizes the risk of mechanical wear. To maintain the long-term high-precision operation of the equipment, silicon carbide aerostatic slideway is equipped with a grating scale closed-loop feedback system to ensure high-precision displacement positioning. These ingenious designs significantly extends the service life of silicon carbide aerostatic slideway, and greatly lowers the cost of equipment maintenance.

Application scenarios of silicon carbide aerostatic slideway

1. Semiconductor Manufacturing: it is used in wafer stage positioning for photolithography machines, coordinate measuring machines, panel inspection equipment, optical processing equipment, and battery production equipment.

2. Precision Measurement: It is used in coordinate measuring machines, position turntables.

3. Other High-End manufacturing applications: it is used in aerospace simulation platforms, automotive precision instruments, laser processing equipment, and biochip manipulators.

Semicorex offers high-quality silicon carbide components. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com