- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Introduction To Three Type Of Oxidation Processes

2025-10-19

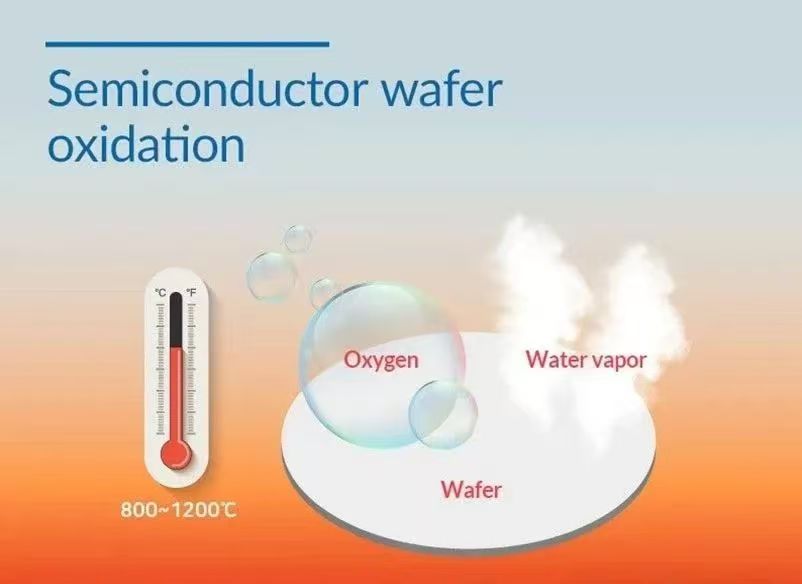

Oxidation process refers to the process of providing oxidants (such as oxygen, water vapor) and thermal energy on silicon wafers, causing a chemical reaction between silicon and the oxidants to form a protective silicon dioxide (SiO₂) film.

Three type of oxidation processes

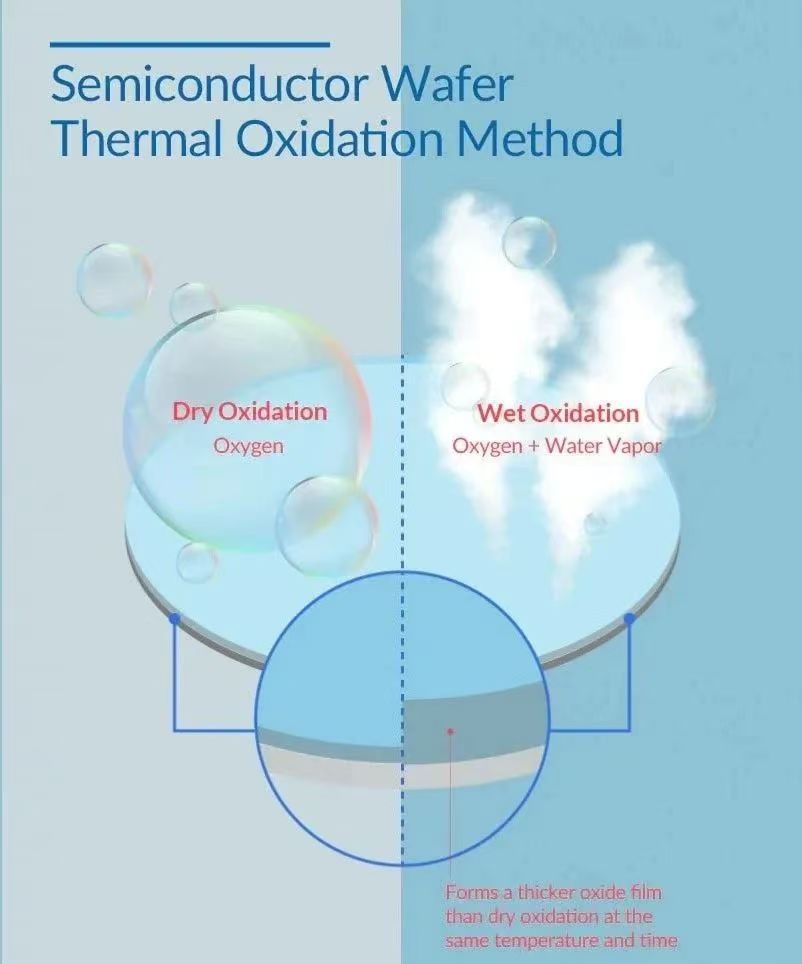

1.Dry oxidation:

In dry oxidation process, wafers are subjected to a high-temperature environment enriched with pure O₂ for oxidation. Dry oxidation proceeds slowly because oxygen molecules are heavier than water molecules. However, it is advantageous for the production of thin, high-quality oxide layers because this slower rate enables more precise control over the thickness of the film. This process can produce a homogeneous, high-density SiO₂ film without producing undesirable byproducts like hydrogen. It is suitable for the production of thin oxide layers in devices that require precise control over oxide thickness and quality, such as MOSFET gate oxides.

2.Wet Oxidation:

Wet oxidation operates by exposing silicon wafers to a high-temperature water vapor, which triggers a chemical reaction between silicon and the vapor to form silicon dioxide (SiO₂). This process produces oxide layers with low uniformity and density and produces undesirable by-products such as H₂, which are typically not used in the core process. This is because the growth rate of the oxide film is faster because the reactivity of water vapor is higher than that of pure oxygen. Therefore, wet oxidation are usually not used in the core processes of semiconductor manufacturing.

3.Radical Oxidation:

In the radical oxidation process, the silicon wafer is heated to a high temperature , at which point oxygen atoms and hydrogen molecules combine to form highly active free radical gases. These gases react with the silicon wafer to form a SiO₂ film.

Its standout advantage is high reactivity: it can form uniform films in hard-to-reach areas (e.g., rounded corners) and on low-reactivity materials (e.g., silicon nitride). This makes it well-suited for manufacturing complex structures like 3D semiconductors that demand highly uniform, high-quality oxide films.

Semicorex offers high-quality SiC parts for diffusion processes. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.