- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Isostatic Graphite Manufacturers, Suppliers, Factory

- View as

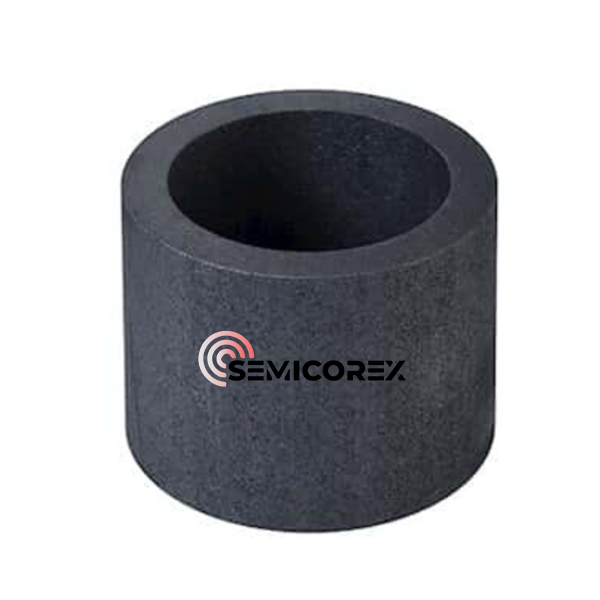

Graphite Bushing

Semicorex Graphite Bushing, with its unique material characteristics and adaptability, plays a critical role in enhancing the performance and longevity of mechanical systems, underscoring its significance in modern engineering and manufacturing processes.

Read MoreSend InquiryGraphite Ring

Semicorex Graphite Ring's ability to withstand extreme conditions and ease of installation make them an indispensable component in industries such as hydraulics, pneumatics, and heat exchangers.

Read MoreSend InquiryHigh-purity Graphite Crucible

Semicorex High-purity Graphite Crucible's applications range from semiconductor manufacturing to metal casting and jewelry making, illustrating its versatility and indispensability.

Read MoreSend InquiryGraphite Bipolar Plate

Semicorex Graphite Bipolar Plate is an indispensable component in modern energy systems, offering a blend of superior electrical conductivity, thermal management, and mechanical strength. Its application in PEM fuel cells and flow batteries highlights its critical role in advancing clean energy technologies.

Read MoreSend InquiryRefined Graphite Mold

Semicorex Refined Graphite Mold is a versatile and efficient tool in various industrial casting and molding processes. Its high purity, low thermal expansion, and excellent surface finish make it a preferred choice for applications requiring precision and quality.

Read MoreSend InquiryGraphite Seed Chunk

The Graphite Seed Chunk plays a critical role in the production of electronic-grade polysilicon, particularly within the heating systems of single crystal furnaces.

Read MoreSend Inquiry