- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

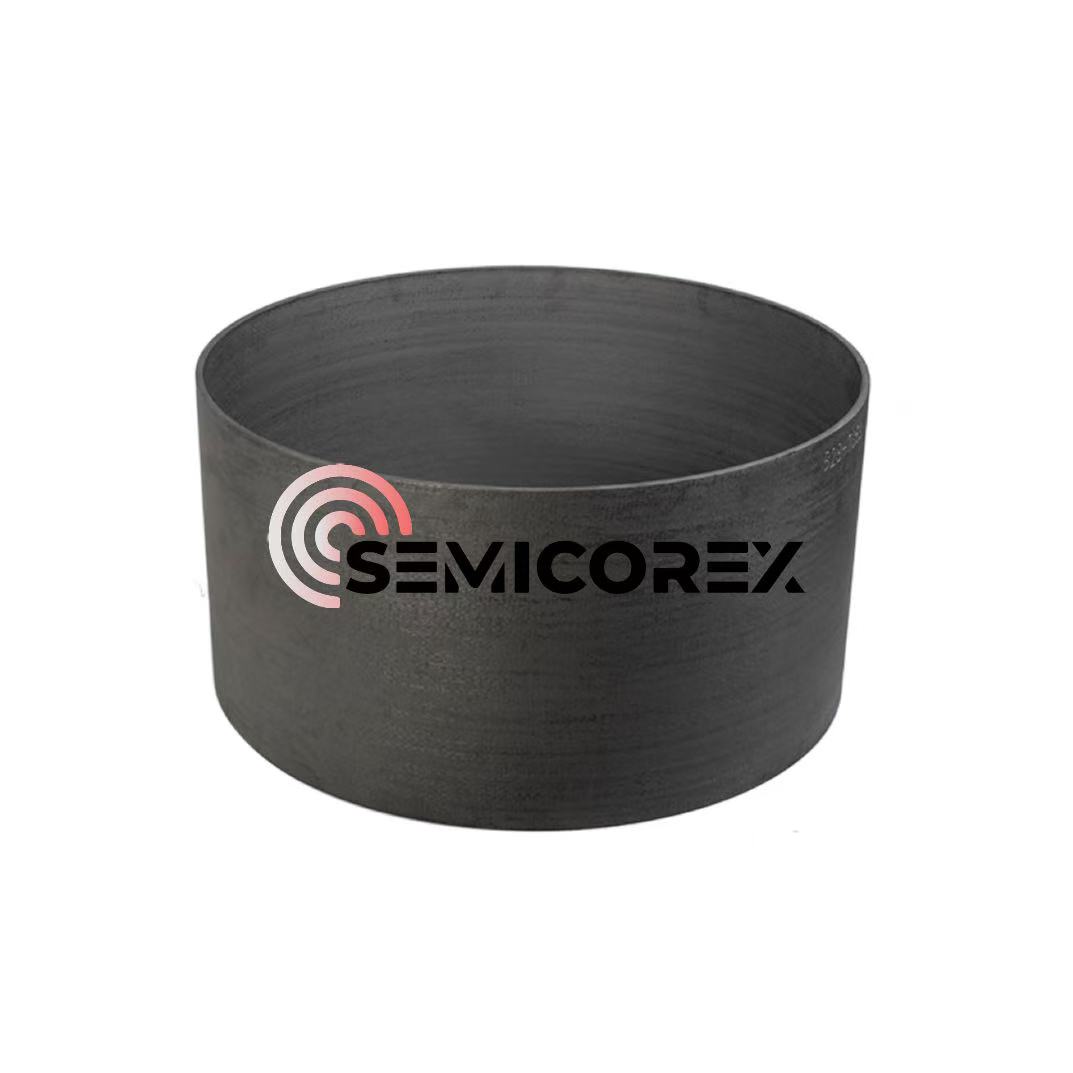

C/C Thermal Insulation Cylinders

C/C thermal insulation cylinders are the high-performing thermal insulation components used in the thermal field system for single-crystal silicon growth, serving both thermal insulation and support functions. With exceptional thermal insulation performance, excellent structural strength, and competitive price, Semicorex C/C thermal insulation cylinders stand as the ideal option for your high-quality crystal growth processes.

Send Inquiry

C/C thermal insulation cylinders, along with crucibles, heaters, flow guide tubes, and crucible shafts, constitute the thermal field system required for crystal growth. C/C thermal insulation cylinders are commonly installed around the heaters in the high-temperature crystal growth furnace to create a thermal insulation layer that can significantly prevent heat loss of semiconductor materials within the crucible.

Because carbon-carbon composites have extremely low thermal conductivity, they can effectively reduce heat transfer between the thermal field and the external environment. C/C thermal insulation cylinders are made from carbon-carbon composites, delivering exceptional thermal insulation property and creating a stable and uniform thermal field for crystal growth process. This consistent thermal environment directly enhance crystal quality (e.g., reduced defects, improved uniformity) and increase production yields.

In addition to their thermal insulation performance, C/C thermal insulation cylinders also deliver reliable mechanical support for adjacent components (such as crucibles and heaters), ensuring the structural stability and operational reliability of the entire thermal field during high-temperature processes. Their material properties of low-density and lightweight offer many benefits to end users in actual operations, facilitating a more convenient on-site replacement process and enhancing operational efficiency in production.

To better serve our valued customers, Semicorex supports custom configurations of C/C thermal insulation cylinders, including size, shape, and structural details, to seamlessly match a variety of single crystal furnace designs.